Every refueling station relies on a complex system of interconnected components that work together to ensure smooth operation. These mechanisms are designed to deliver fuel safely and efficiently to vehicles. A closer look at how each element functions provides valuable insights into the overall process and its maintenance requirements.

The equipment involved is made up of various essential elements, each with a specific role to play in the operation. From the initial flow of liquid to the final delivery to the vehicle, each part contributes to the system’s accuracy and reliability. Understanding how these components work together can help identify potential issues and improve the longevity of the entire setup.

Understanding Fuel Dispenser Components

Refueling systems consist of various key elements that enable the controlled transfer of liquids to vehicles. These components interact seamlessly to ensure the process is safe, efficient, and precise. Each section plays a critical role in maintaining the integrity of the operation, from regulating the flow to ensuring accurate measurement and preventing leaks.

Among the most vital parts are the mechanisms responsible for controlling the flow rate and the safety features designed to shut off or adjust delivery when needed. The structure also includes elements for monitoring and measuring the quantity dispensed, ensuring that every transaction is recorded accurately. Each piece is built to withstand the wear and tear of constant use, guaranteeing long-term reliability and minimizing the risk of malfunctions.

Key Parts of a Fuel Dispenser System

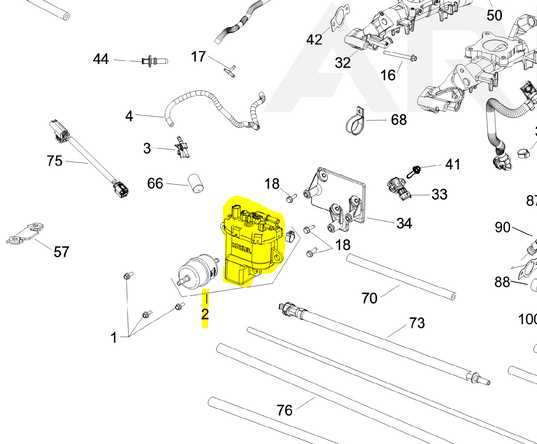

The system used for liquid transfer at service stations is composed of several crucial components that work together to ensure proper functionality. Each element is designed to fulfill a specific role in managing the flow, monitoring the quantity, and ensuring the safety of the entire process. Understanding these key pieces helps in identifying potential areas for maintenance and improvement.

Among the primary components are the flow control valves, which regulate the liquid’s movement, and the metering devices, which measure the exact amount dispensed. Additionally, safety mechanisms, such as automatic shut-off systems, play a vital role in preventing overflows or accidents. These elements, along with others, form the backbone of a reliable and efficient refueling operation, providing accuracy and consistency every time the system is used.

How Fuel Dispensers Work Internally

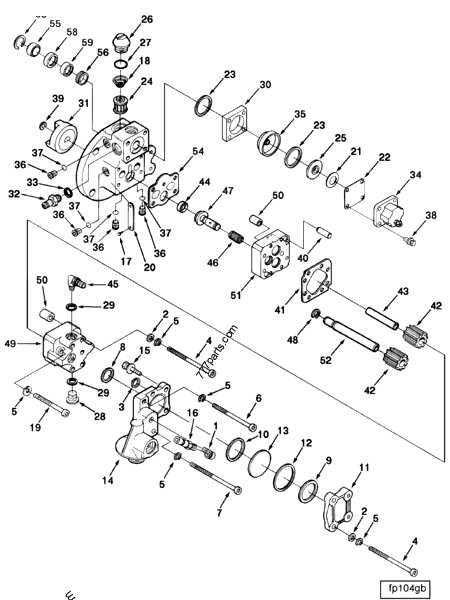

The internal workings of liquid dispensing systems are designed to ensure a smooth, accurate, and secure transfer process. These systems are carefully engineered to handle various functions simultaneously, from controlling the flow of liquid to monitoring the total amount dispensed. Understanding how the internal mechanisms interact can provide a clearer picture of how each element contributes to the system’s overall efficiency.

The process begins as the operator activates the system, initiating a sequence of actions. Key functions are carried out by different components that work together in the following order:

- Flow Control: Valves are opened to allow the liquid to flow through the system, with adjustments made to regulate the rate.

- Measurement: A metering unit tracks the amount dispensed, ensuring the correct quantity is transferred to the vehicle.

- Safety Features: Sensors and automatic shut-off mechanisms monitor the delivery, halting the process if any irregularities are detected.

These internal systems work in unison, allowing for a fast and safe transaction with minimal risk of error or malfunction. Regular maintenance and understanding of how each part functions are essential for ensuring the system operates at peak performance over time.