When it comes to maintaining and repairing your watercraft, having a clear understanding of its core components is essential. This knowledge allows you to address any mechanical issues quickly and efficiently. Whether you’re a seasoned boater or a first-time owner, knowing how each part functions ensures optimal performance and longevity of your vessel.

Identifying individual components is key to diagnosing problems. Each element of your boat works in harmony with others, and sometimes a small malfunction in one part can cause a larger issue. With a visual reference of the system’s layout, you can easily pinpoint where a malfunction might lie and act accordingly.

Being able to troubleshoot common problems with confidence is crucial. This guide will walk you through the essential parts of the system, how they interact, and how to fix common issues. Having this knowledge on hand will save you time, money, and frustration when dealing with mechanical failures.

Understanding Gator Tail Parts and Functions

Every boat is made up of several integral components, each serving a specific role to ensure smooth operation and efficiency. Understanding the individual elements and how they work together is key to optimizing performance. By examining the function and design of each section, one can gain insight into how they contribute to the overall functionality of the watercraft.

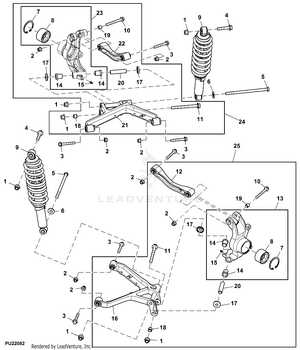

The propulsion system plays a vital role in determining the speed and maneuverability of the vessel. It consists of mechanisms that convert energy into forward motion, making it possible to navigate various water conditions. Connected to this system, the steering apparatus allows for precise directional control, offering the captain the ability to adjust the boat’s course with ease.

Additionally, the structural framework ensures that the boat remains stable and resilient in different environments. This component supports the other systems and protects the vessel from damage. To maintain smooth operation, the control elements must be regularly serviced, as they regulate power distribution and contribute to overall efficiency.

Finally, the housing and mounting elements are essential for securing these systems in place. These components provide the necessary foundation for other parts to operate effectively, ensuring durability and long-lasting performance.

How to Use a Gator Tail Parts Diagram

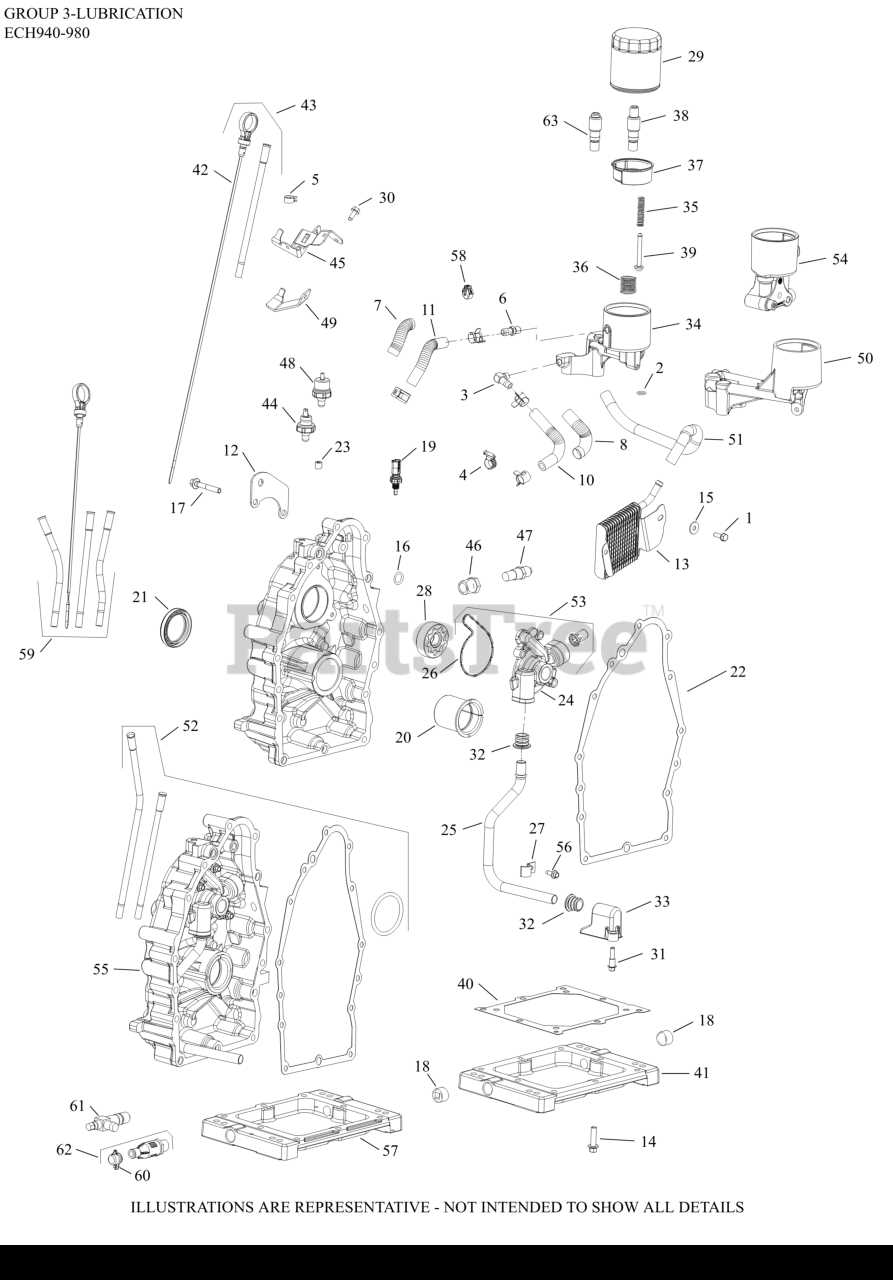

Understanding how to read and interpret technical illustrations is essential when maintaining or repairing any type of machinery. These visuals provide a detailed representation of a system’s components and their relationships, enabling users to identify specific elements and their functions. Properly utilizing such illustrations allows for more efficient troubleshooting and accurate reassembly.

To begin, it’s important to familiarize yourself with the layout of the visual representation. Each component will typically be numbered or labeled, corresponding to a list that explains its function and specifications. By referencing this guide, you can quickly locate the part in question and understand how it interacts with the rest of the system.

Additionally, pay attention to any notes or annotations that highlight special instructions, common issues, or installation tips. These can help you avoid mistakes and ensure the correct procedures are followed. Finally, using this resource in conjunction with the actual unit will provide a comprehensive understanding of how each element fits into the overall structure.

Common Issues and Repairs for Gator Tail Parts

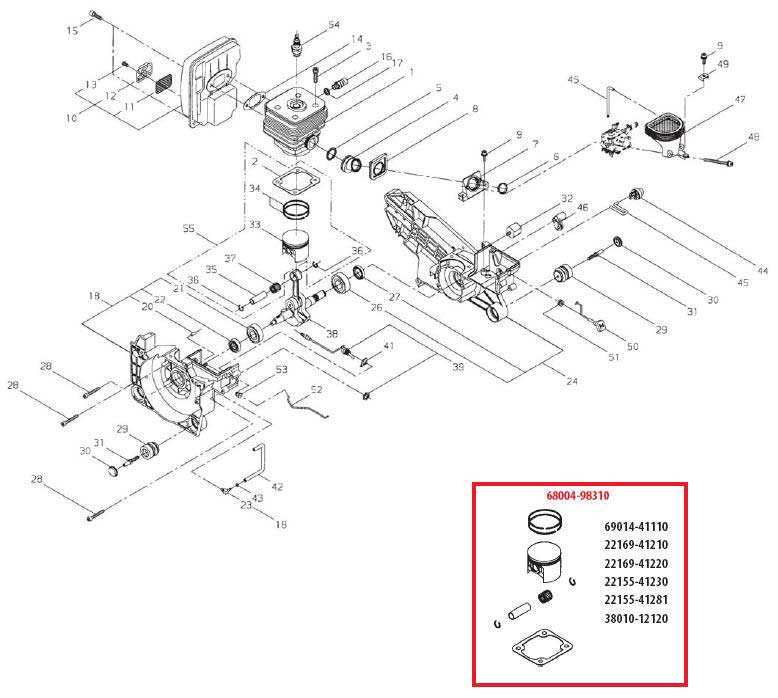

When operating mechanical systems, certain components may experience wear or malfunction due to constant use or external factors. Recognizing common issues early and understanding how to address them can prevent further damage and ensure longevity. Many of the typical problems are related to improper maintenance, environmental conditions, or simply the aging of key elements. Knowing what to look for and how to repair these issues is essential for keeping the unit in top condition.

Mechanical Failures

One of the most common issues is mechanical failure caused by wear on moving parts. Over time, certain elements, such as gears or connectors, may degrade, leading to reduced performance or complete breakdowns. Regular inspection and lubrication can minimize these risks. If a failure occurs, it’s often necessary to replace the worn component with a compatible replacement to restore functionality.

Hydraulic Problems

Another frequent issue arises from the hydraulic system, which can develop leaks or lose pressure. This typically happens due to worn seals or hoses. If you notice a drop in performance or visible leaks, it is important to identify the source of the problem. Replacing damaged seals or tightening loose connections can help restore proper function. In more severe cases, the entire hydraulic system may need to be flushed and refilled to ensure smooth operation.