When maintaining a power generator, it’s crucial to understand its components and how they work together. Knowing the structure and functions of each part will ensure smooth operation and help prevent potential issues.

In this guide, we will explore the essential elements of a typical machine, providing insights into each piece’s role. We will also cover how to interpret visual representations of the system, allowing you to easily identify and address any concerns that may arise.

Proper knowledge of the internal setup not only aids in maintenance but also helps in making informed decisions when it comes to repairs or replacements. By familiarizing yourself with these key components, you’ll be able to extend the lifespan of your equipment and avoid common pitfalls.

Understanding the parts will empower you to troubleshoot effectively, ensuring your generator operates at its best for years to come.

Understanding the Generator Components

To ensure optimal performance, it’s essential to become familiar with the key elements that make up a generator. Each component plays a specific role in providing reliable power and efficiency. Gaining a clear understanding of these components allows users to troubleshoot issues and perform proper maintenance, keeping the machine running smoothly for years.

Core Components of a Power Generator

The main parts of a generator work together to convert mechanical energy into electrical energy. These include the engine, alternator, fuel system, control panel, and exhaust system. Each part contributes to the overall functionality, ensuring the generator operates effectively when needed. A deeper knowledge of each section helps in understanding how they interact to provide continuous power.

Identifying and Maintaining Essential Elements

Routine inspection and proper care of vital components are crucial for long-term use. Common issues such as fuel line blockages, air filter clogs, and battery wear can be easily spotted and resolved if you know where to look. Regular maintenance keeps the system efficient, preventing unexpected breakdowns and extending the generator’s lifespan.

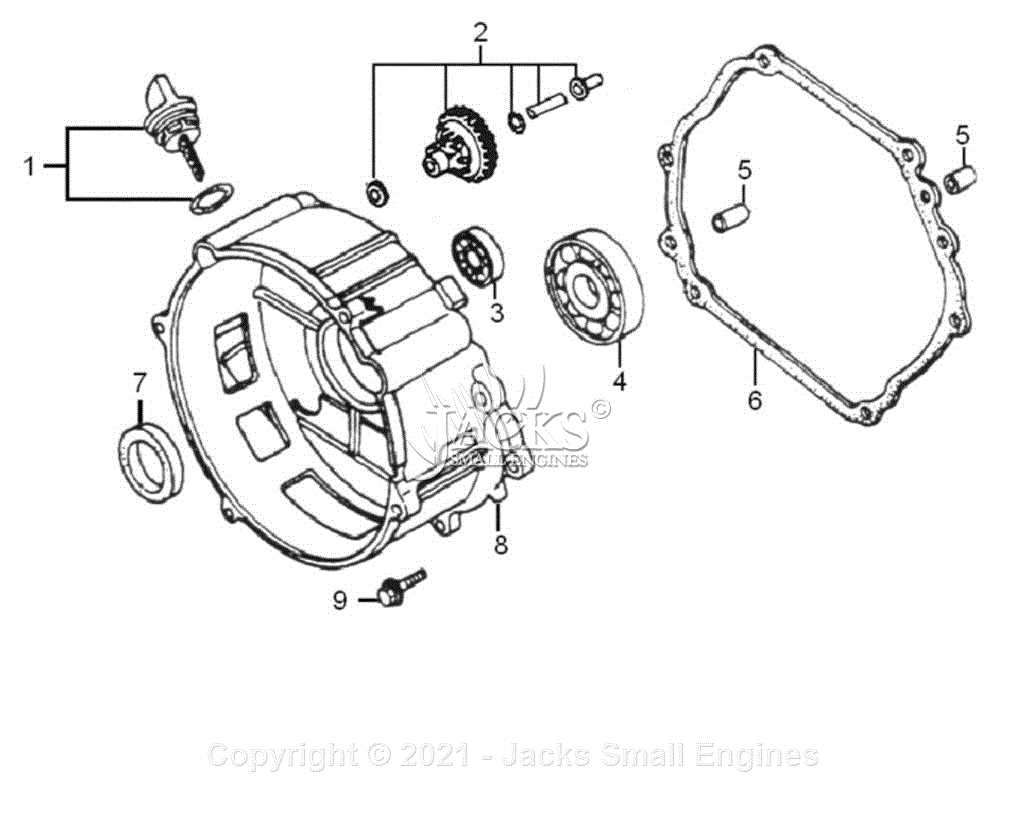

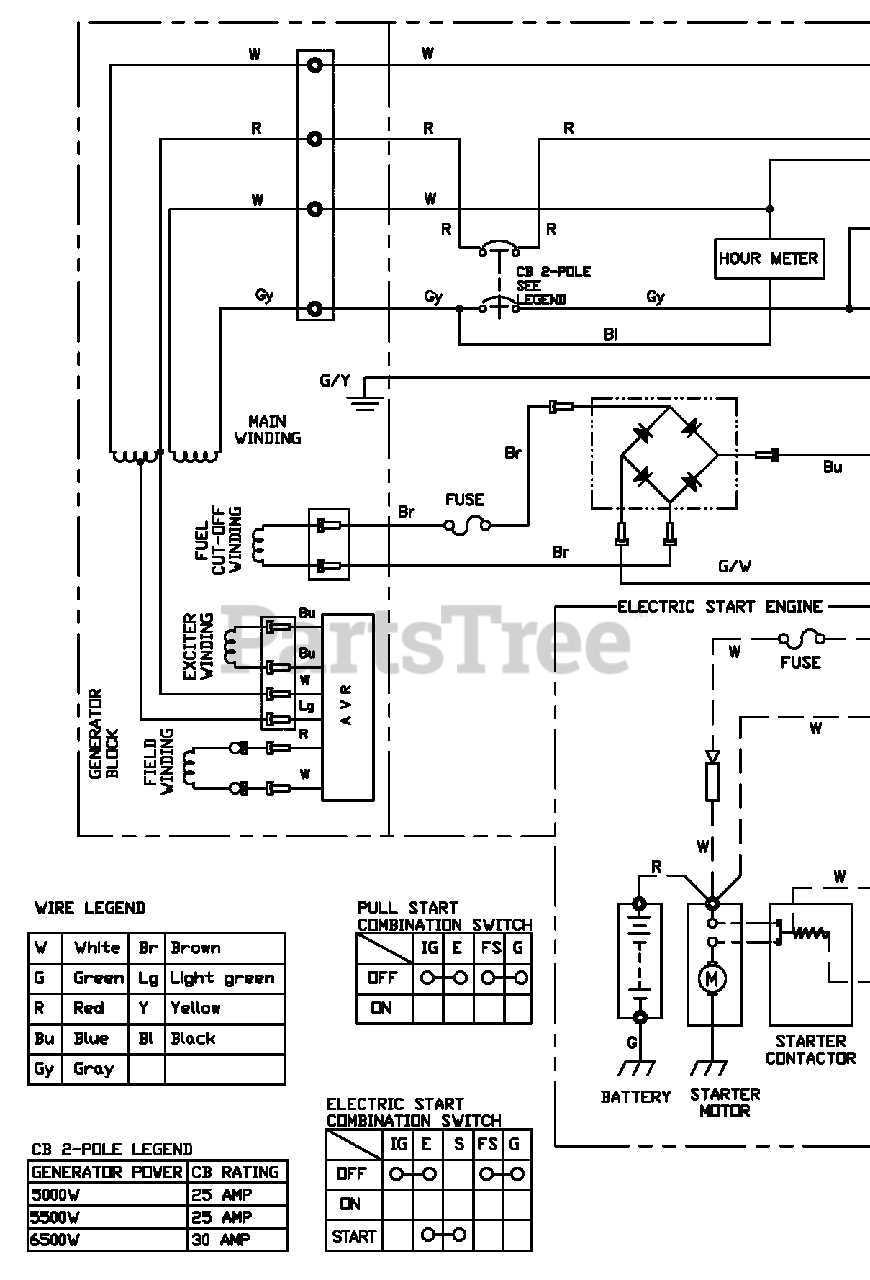

How to Read the Visual Breakdown

Understanding a visual breakdown of a machine is essential for identifying each component and its function. These illustrations or charts are designed to provide a clear view of the system, making it easier to locate and understand individual elements. Knowing how to interpret these diagrams will allow you to quickly identify parts and troubleshoot any issues that arise.

Interpreting the Labels and Symbols

Most visual breakdowns include detailed labels and symbols to describe each part. These indicators usually correspond to specific components and help guide you in identifying them. By paying attention to these details, you can accurately match the labels with the physical parts of the machine. Knowing what each symbol represents ensures you don’t misinterpret the information and make informed decisions during maintenance or repairs.

Following the Layout for Easy Identification

The layout of these visuals is often designed to show how different parts are interconnected. Understanding this arrangement will help you see the flow and function of the system as a whole. Whether it’s the fuel system or the exhaust, recognizing the layout makes it easier to pinpoint specific parts when you need to troubleshoot or replace them. Having a solid grasp of this visual system enables you to act confidently and effectively.

Common Issues and Solutions for Power Generators

Every machine is prone to occasional problems, and power generators are no exception. Understanding the common issues that can arise helps in troubleshooting quickly and efficiently. Addressing these concerns early on can prevent more significant breakdowns and ensure reliable performance when needed most.

One frequent issue is the generator failing to start. This can be due to a variety of factors, such as a dead battery, fuel issues, or spark plug problems. To resolve this, check the battery voltage and connections, inspect the fuel for contamination, and ensure the spark plugs are clean and functioning correctly.

Another common problem is the generator running but not providing sufficient power. This could be caused by an overloaded system or issues with the alternator. To fix this, reduce the load on the generator and check the alternator for any signs of wear or malfunction. Regular maintenance of the engine and its components can help avoid these power-related problems.