When it comes to maintaining and repairing garden equipment, knowing how the various components fit together is essential. A clear visual representation can significantly ease the process of identifying parts, making it easier to address issues and replace worn-out components.

In this section, we will explore the key elements of garden machinery and how they are organized. With a better understanding of the internal structure, users can perform maintenance tasks more efficiently and with greater confidence.

Maintenance and repair become much simpler when each part is easily identifiable. By following a detailed breakdown, you can ensure your equipment operates at peak performance for longer periods. This visual guide serves as a helpful tool for owners who want to prolong the life of their machinery while keeping it in optimal working condition.

Understanding the Machinery Breakdown

When working with outdoor equipment, it is crucial to grasp the arrangement of internal components for proper maintenance and repair. A comprehensive layout of the machinery’s structure enables owners to easily locate and assess individual elements, ensuring smoother troubleshooting and part replacement.

Having a clear guide to the various sections and mechanisms within the machine helps users identify issues quickly. It can also serve as a reference for assembling or disassembling the equipment, allowing for more efficient handling of any repairs or upgrades needed.

Familiarizing yourself with the layout empowers users to make informed decisions about which components need attention. This not only improves the performance of the machine but also reduces the time and cost involved in maintaining it. A well-organized representation ensures that each part is placed in its rightful context, contributing to long-lasting functionality.

Key Components of Garden Cultivating Equipment

Understanding the essential elements that make up garden machinery is vital for ensuring its effective use and maintenance. Each section of the machine plays a crucial role in its overall performance, and knowing how these pieces work together is key to troubleshooting or upgrading the equipment.

Some of the most important components include the engine, transmission, and cultivator blades, each contributing to the device’s power, mobility, and efficiency. Proper knowledge of how these elements interact can help users maintain smooth operation and extend the lifespan of their equipment.

Regular inspection of the major elements is necessary for optimal performance. Identifying wear or damage early on can save time and money in the long run. Understanding the function and placement of each part ensures that necessary repairs or replacements are done efficiently and accurately.

How to Read the Equipment Layout

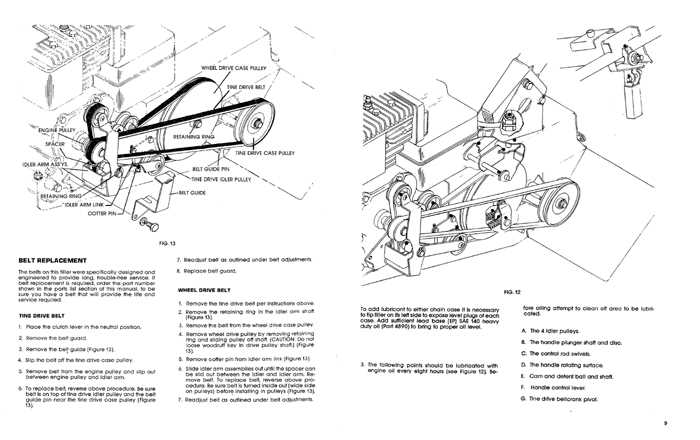

Learning how to interpret a machine’s layout is essential for efficient maintenance and repair. This visual guide provides a detailed representation of the internal components, making it easier to locate and identify each part. Understanding how to read this representation allows users to troubleshoot issues and perform repairs with confidence.

The key to reading such a layout is recognizing the symbols and connections between the various elements. Each section is typically labeled and arranged to reflect the machine’s functional flow, helping you understand the purpose and relationship of each component. Proper familiarity with these markers will allow for quicker identification and smoother operations during repairs.

By following the labeled sections and understanding their placement, users can avoid confusion when working with individual parts. Whether replacing a worn-out component or assembling new parts, interpreting the layout correctly is essential for maintaining the equipment’s performance.