Understanding the inner workings of a spray system is crucial for ensuring its efficiency and longevity. A clear visual representation of the components allows users to easily identify, troubleshoot, and maintain their equipment. By familiarizing yourself with the key elements, you can optimize performance and reduce the likelihood of costly repairs.

Proper maintenance and care of each individual component help to prevent wear and tear that can lead to operational failures. Knowing the exact function of each part and its relationship with others is essential for keeping your sprayer in top condition. Whether you’re a professional or a DIY enthusiast, this guide provides you with all the necessary information to manage your equipment effectively.

By using an accurate breakdown of the system, you can quickly identify any issues and address them before they turn into major problems. With this knowledge, you’ll be better prepared to ensure smooth operations and extend the lifespan of your sprayer.

Understanding Key Components of the Sprayer System

In order to properly operate and maintain a spraying device, it’s essential to grasp the different elements that make up the system. Each component plays a vital role in ensuring the equipment runs smoothly and efficiently. From the pump to the spray gun, every part has its specific function, contributing to the overall performance and durability of the machine.

For instance, the pump is responsible for pressurizing the material, enabling it to flow through the hose and out of the nozzle with force. The spray gun, on the other hand, controls the delivery and pattern of the material being sprayed. Understanding how each of these components works together allows for more precise maintenance, reduces the risk of malfunctions, and ensures optimal results every time.

Familiarizing yourself with the system’s components not only helps in recognizing potential issues but also empowers you to troubleshoot and replace parts when needed. Proper care and knowledge of the key elements can significantly extend the lifespan of your equipment, preventing unnecessary repairs and downtime.

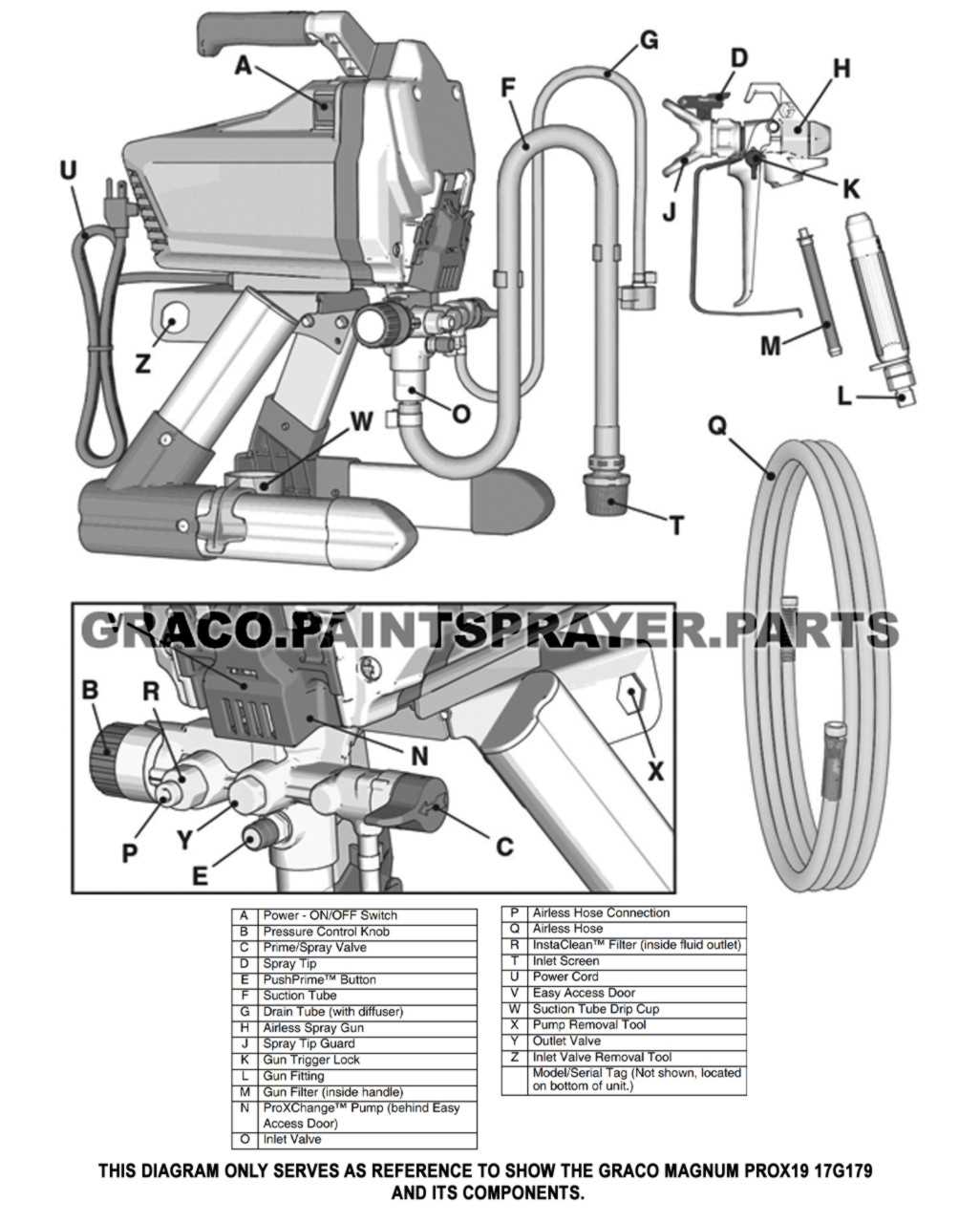

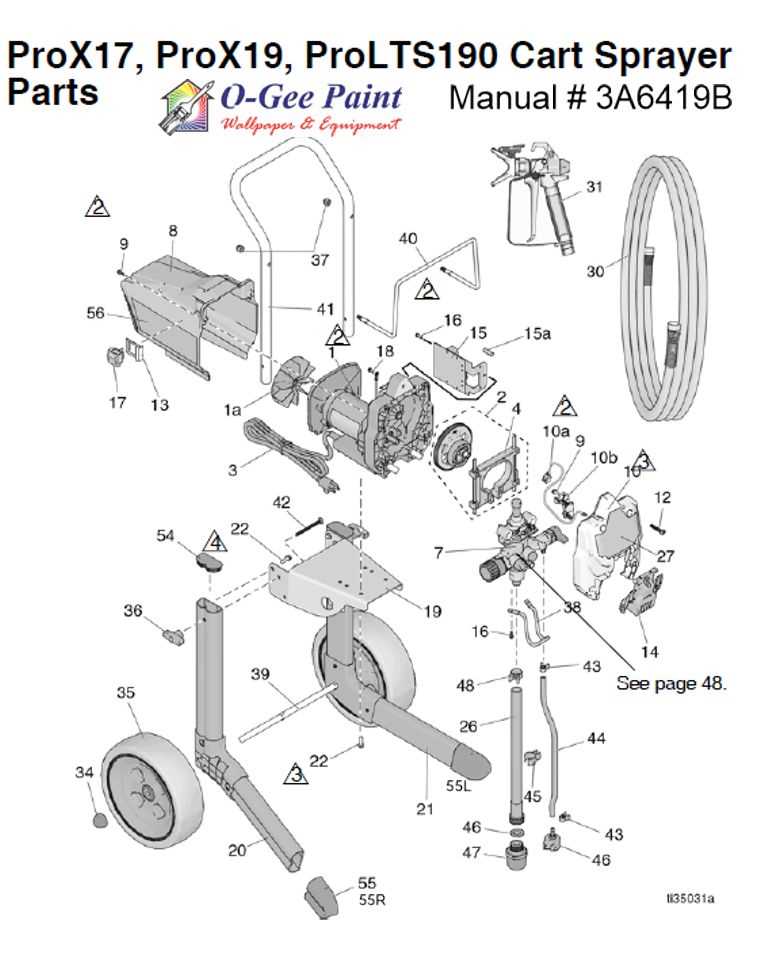

Identifying Key Parts in the Diagram

Recognizing the essential components of your sprayer system is crucial for effective maintenance and troubleshooting. A well-organized visual guide helps you pinpoint each part and understand its role within the overall setup. By studying the layout, you can quickly locate individual elements, making it easier to assess their condition and replace them when necessary.

Each section of the system serves a unique purpose, from the pressure control mechanism to the spray nozzle. For example, the intake valve regulates the flow of liquid, while the motor controls the pressure needed for proper spraying. Understanding where each component is located within the system allows for quicker repairs and more efficient operation.

Once you identify and familiarize yourself with the key components, it becomes much easier to identify any potential issues and take proactive steps to address them. This knowledge not only simplifies the repair process but also helps optimize performance, extending the life of your equipment.

How to Maintain Your Sprayer Components

Proper maintenance is key to ensuring the longevity and optimal performance of your spraying system. Regular inspection and care of the different elements prevent malfunctions and reduce the need for costly repairs. A well-maintained sprayer not only works more efficiently but also delivers better results and extends the lifespan of each component.

Regular Cleaning and Inspection

Cleaning the system after every use is essential. Residue buildup can clog components, affecting performance. Pay special attention to the intake valve, nozzle, and hose, as these areas are most prone to blockages. Regularly inspect for any signs of wear, cracks, or leaks, especially in high-pressure areas. This proactive approach can help you identify issues early and address them before they cause major disruptions.

Lubrication and Replacement of Worn Components

Applying appropriate lubricants to moving parts ensures smooth operation and reduces friction. Be sure to replace any worn-out seals, gaskets, or other components that could impact the efficiency of the system. Keeping spare parts on hand can save time and prevent delays when a replacement is needed. Regularly check and replace filters as well to maintain proper fluid flow and prevent dirt and debris from damaging internal components.