When maintaining or repairing your equipment, knowing how its components are arranged and function together is essential. Understanding the layout and interaction of various elements ensures effective troubleshooting and helps you make informed decisions about replacements or adjustments.

Accurate identification of each element within your machine can prevent unnecessary mistakes during repairs. By exploring the different sections and their roles, you gain a deeper insight into how the system works, making it easier to diagnose issues and perform maintenance tasks efficiently.

Whether you’re a professional technician or a dedicated hobbyist, having a comprehensive overview of your machine’s internal structure can save you time and effort. This knowledge allows for quicker resolutions and enhances the longevity of the equipment, ensuring smooth operation throughout its lifecycle.

Understanding the Mower Components

In any mechanical system, it’s crucial to comprehend how the various elements work together. Each section, whether it’s a drive mechanism or a cutting system, plays a specific role in the overall performance. By understanding how each part interacts, users can diagnose issues more effectively and perform maintenance tasks with confidence.

Key Elements of the Mower

The main components of the machine include the engine, drive belt, blades, and hydraulic system. These work together to ensure smooth operation. The engine powers the system, while the belt transfers motion to the cutting blades. The hydraulic components control lifting and lowering mechanisms, enhancing efficiency during operation.

Importance of Regular Maintenance

Regular inspection and maintenance of each element can significantly extend the lifespan of the machine. Identifying wear and tear early ensures that you can replace or repair parts before they cause more severe damage. Taking the time to understand how each part functions will result in better care and fewer breakdowns over time.

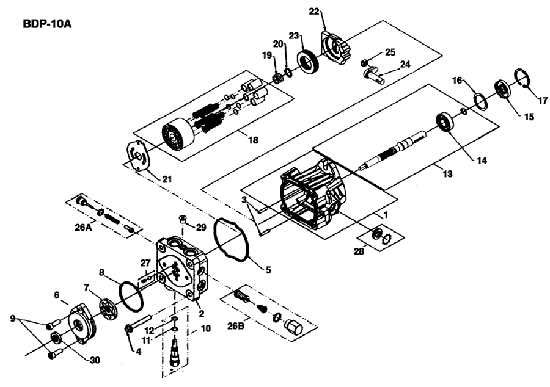

Detailed Breakdown for Easy Maintenance

To keep your machinery running smoothly, it’s essential to know the specific components that make up the system. A thorough understanding of each section, from the engine to the cutting system, allows you to maintain and repair your equipment more efficiently. By breaking down the structure into smaller elements, users can identify which parts need attention during regular checks or when issues arise.

Identifying Key Sections

The engine is the heart of the system, powering the entire unit, while the transmission ensures the correct movement of the wheels and cutting blades. The hydraulic system enables adjustments to various components, like the height of the deck, ensuring precise operation. Additionally, components like belts and pulleys must be kept in good condition for optimal function.

Maintenance Tips for Longevity

Regular cleaning of the components prevents dirt and debris from accumulating, which could otherwise lead to wear. It’s also important to check fluid levels in the engine and hydraulic system periodically. Regular inspections of the belts and blades help detect any signs of damage, ensuring that you can address minor issues before they lead to bigger problems.

How to Identify Spare Components

Identifying the correct replacement elements for your equipment is crucial for effective maintenance. Knowing how to recognize and distinguish between various components ensures that you can order the right parts, preventing delays in repairs and minimizing downtime. Familiarity with each section’s specifications and functionality helps streamline the replacement process.

Recognizing Common Replacements

Common elements that often require replacement include belts, blades, and filters. It’s essential to understand the specifications for each, such as the size, material, and functionality, to ensure compatibility. Checking the model and serial number can help you find the exact matches for the equipment, reducing the chance of ordering incorrect replacements.

Using Manufacturer Resources

Consulting the manual or manufacturer’s website is one of the best ways to identify the correct replacements. These resources typically include detailed descriptions, images, and part numbers, making it easier to locate the components you need. Being thorough in your search and confirming the exact model ensures you’re getting the correct replacements for your equipment’s specifications.