When it comes to maintaining and repairing your equipment, having a clear view of its individual components is crucial. A detailed map of the machine’s internal structure can simplify repairs, help identify worn-out parts, and ensure smooth operation. This approach enhances the overall experience and efficiency of ownership.

By breaking down the machinery into its main sections, owners can better understand how each part contributes to the overall function. Whether you are troubleshooting an issue or performing routine maintenance, knowing the role of each component is essential for effective repair and upkeep.

Familiarity with each element not only aids in quick fixes but also helps in preventing potential problems. Regular inspection of these parts can save time and money in the long run, ensuring that your equipment remains in top shape.

Understanding Key Components of Your Mower

Every machine is made up of various essential elements that work together to achieve optimal performance. A clear understanding of these components helps ensure proper operation and easier troubleshooting when something goes wrong. Whether you’re an experienced user or a beginner, knowing the function of each individual part is crucial for maintaining your equipment.

The engine, drive system, and cutting mechanism are the primary systems that contribute to the overall functionality of your mower. Each system relies on a variety of specialized components that, when in good condition, ensure efficiency and smooth performance. Identifying and understanding these parts can make routine maintenance more effective and help prevent major issues from developing.

Properly diagnosing problems requires knowing how each piece interacts with the others. With this knowledge, you can identify wear and tear, replace defective items, and keep your mower functioning at its best. Keeping track of the key components and their roles in the system ensures that repairs are done quickly and accurately, saving both time and money.

How to Use the Parts Diagram Effectively

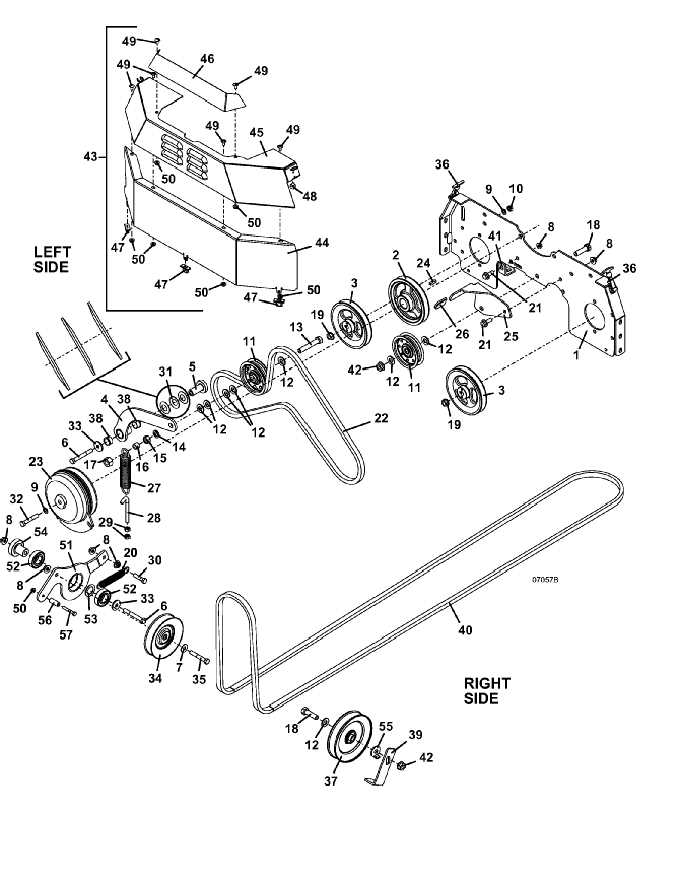

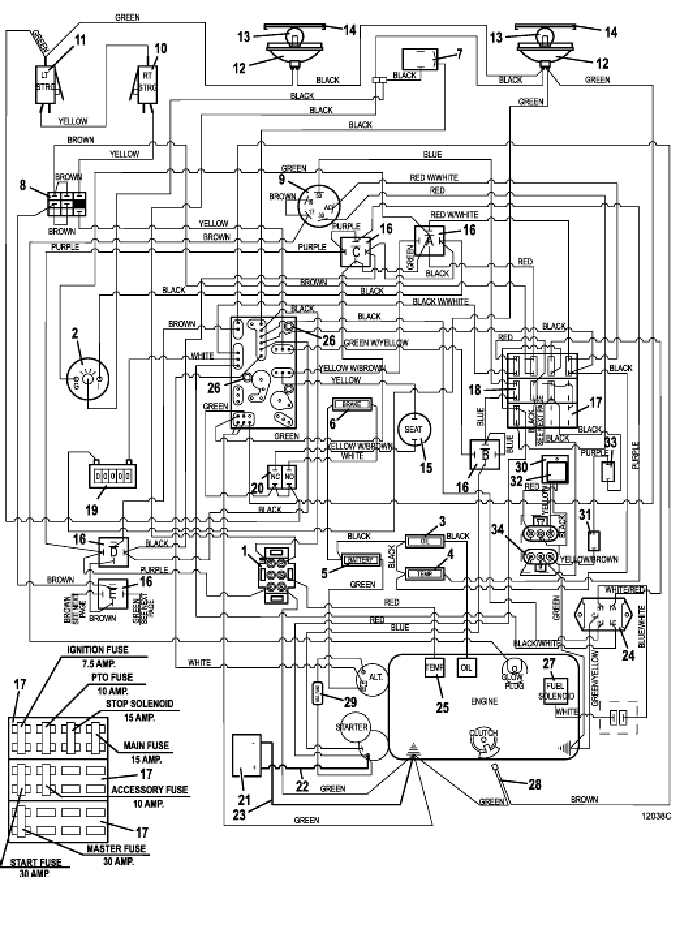

Utilizing a detailed visual reference of your machine’s internal layout is an invaluable tool for both maintenance and repairs. By carefully examining this reference, you can easily identify the exact locations of components and understand their connections. This guide serves as a map to help you navigate your equipment’s design and keep it functioning optimally.

Start by familiarizing yourself with the overall structure. Focus on major sections like the engine, transmission, and cutting mechanisms. Once you have an understanding of these key areas, you can zoom in on smaller components and learn how they contribute to the bigger picture. This process will allow you to troubleshoot problems more effectively and determine which parts need attention.

Attention to detail is essential when using the reference to find specific parts. Pay close attention to the part numbers and labels, as they will guide you to the correct replacement items. Having this knowledge ensures that you select the right components for repairs, saving time and reducing the risk of errors.

Common Issues and Solutions for Your Mower

Like any complex machine, your equipment can encounter issues over time. Recognizing common problems early can help prevent more serious damage and reduce repair costs. By understanding typical faults and their solutions, you can ensure that your mower remains in good working condition for years to come.

One common issue is the failure of the cutting mechanism. Over time, blades can become dull, damaged, or misaligned, causing uneven cuts or poor performance. Regular inspection and sharpening of the blades can prevent this. If blades are beyond repair, replacing them with high-quality alternatives is essential for maintaining efficiency.

Another frequent problem is the malfunction of the drive system. This can manifest as difficulty moving the machine or strange noises during operation. In many cases, the issue can be traced to worn-out belts or gears. Replacing these parts and ensuring proper tension can resolve the issue and restore smooth operation.