When working with machinery, understanding the internal structure and layout of its critical elements is essential for efficient operation and repair. A clear overview of each individual component provides insight into how the system functions and how to troubleshoot potential issues. This knowledge is particularly useful for both novice users and experienced technicians looking to maintain or repair their equipment.

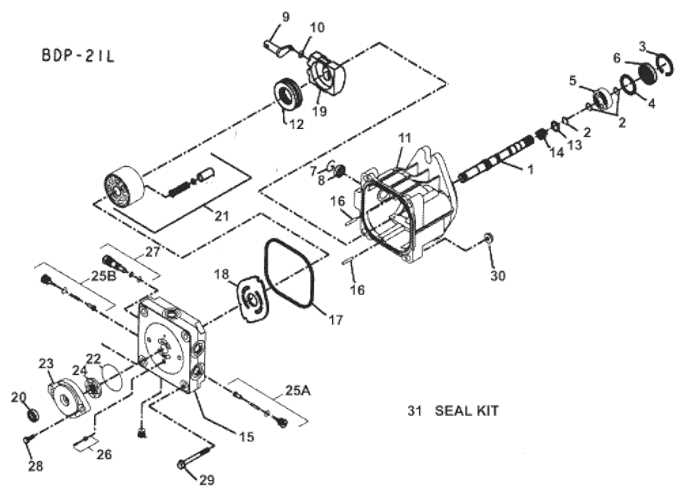

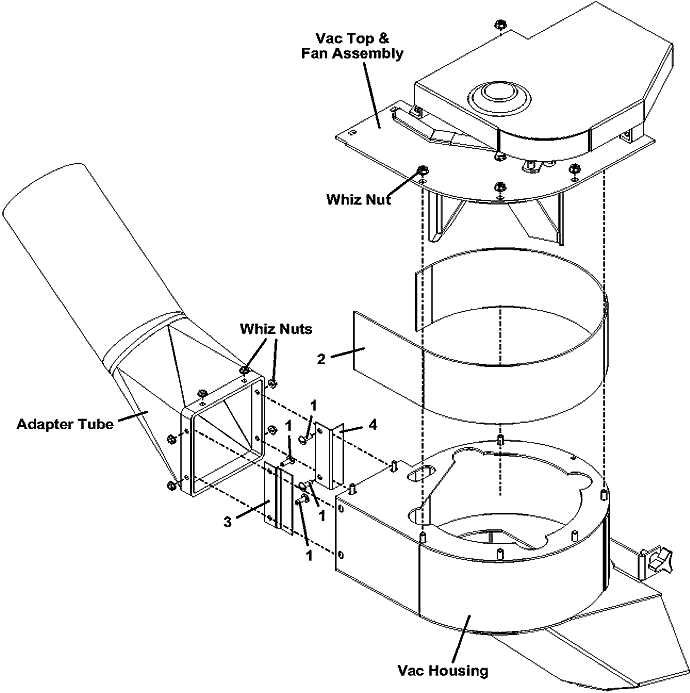

Accurate diagrams offer an essential visual representation of each piece’s location and function within the system. By having a detailed map of all relevant components, users can confidently approach any maintenance tasks, knowing exactly where each part fits into the overall mechanism.

Proper care and attention to these components can significantly extend the lifespan of the equipment. Regular checks and understanding common issues based on component placement ensures smoother operation and fewer breakdowns. Emphasizing the importance of routine inspections, this guide will help you stay on top of necessary maintenance, ensuring peak performance at all times.

Understanding Key Components

To ensure optimal performance and longevity of any equipment, it is crucial to have a comprehensive understanding of its core elements. Each individual component plays a significant role in the overall functionality, and being familiar with how they work together can make troubleshooting and maintenance much more efficient. Identifying the function and location of each part will help users make informed decisions when it comes to repairs or replacements.

Critical Mechanical Elements

The machinery’s mechanical components are the backbone of its functionality. These elements typically include moving parts responsible for driving the system, such as engines, gears, and pulleys. Understanding the layout and interactions of these mechanical parts ensures that any wear and tear is detected early, preventing larger, more costly issues. Keeping these elements well-lubricated and properly adjusted can help maintain smooth operation.

Electrical and Control Systems

Alongside the mechanical structure, the electrical and control systems are vital in coordinating the machine’s operations. These components include wiring, sensors, and switches that facilitate communication between the machine’s internal elements. Understanding how these systems interact with the mechanical parts allows for better control and diagnostic capabilities. Regularly inspecting the wiring and connections is essential for preventing electrical failures that could halt the machine’s performance.

Key Elements Explained

Understanding the critical components of any machinery is essential for efficient use and maintenance. Each part serves a specific purpose, contributing to the smooth operation of the overall system. In this section, we will explore the main elements that are integral to the functioning of the machine, providing insight into their roles and how they interact with one another.

Drive and Power Mechanisms

The driving and power systems are fundamental to the operation of the machine. These include the engine and transmission components responsible for converting energy into motion. Properly maintaining these elements ensures that the machine runs smoothly and that its power output remains consistent. Regular checks and adjustments to these systems can help prevent performance degradation and unexpected breakdowns.

Control and Safety Features

The control system coordinates the machine’s operations, allowing the user to manage its functions with precision. This system typically includes switches, levers, and electronic controllers that regulate power and speed. Safety mechanisms, such as emergency stops and sensors, are integrated into the control system to protect both the user and the equipment. Ensuring these components are in optimal condition is crucial for safe operation.

Maintenance Tips for Key Components

Regular maintenance is crucial to ensure that machinery continues to operate efficiently and effectively. By performing routine checks and taking preventive measures, users can avoid costly repairs and extend the lifespan of the equipment. This section offers valuable tips for maintaining the critical components, focusing on lubrication, adjustments, and proper care to keep everything running smoothly.

Lubrication and Cleaning

Keeping moving parts well-lubricated is essential for reducing friction and preventing wear and tear. Regularly applying the appropriate lubricants to gears, pulleys, and other mechanical elements ensures smooth operation and helps avoid overheating. Additionally, cleaning the components after each use removes dirt and debris that can contribute to damage over time. Using the right cleaning solutions and techniques can significantly improve the machine’s longevity.

Inspection and Adjustments

Periodic inspections are key to identifying potential issues before they become major problems. Check for signs of wear, cracks, or loose connections in both mechanical and electrical components. Adjustments to belts, tension, or other settings may be necessary to maintain peak performance. Ensuring that all connections are tight and secure will also help avoid malfunctions during use.