Understanding the various components that make up a machine is crucial for its proper maintenance and repair. This section delves into the essential elements that contribute to its overall functionality, providing insight into how each piece interacts to ensure optimal performance. A clear overview of these elements can simplify troubleshooting and guide users through necessary replacements or upgrades.

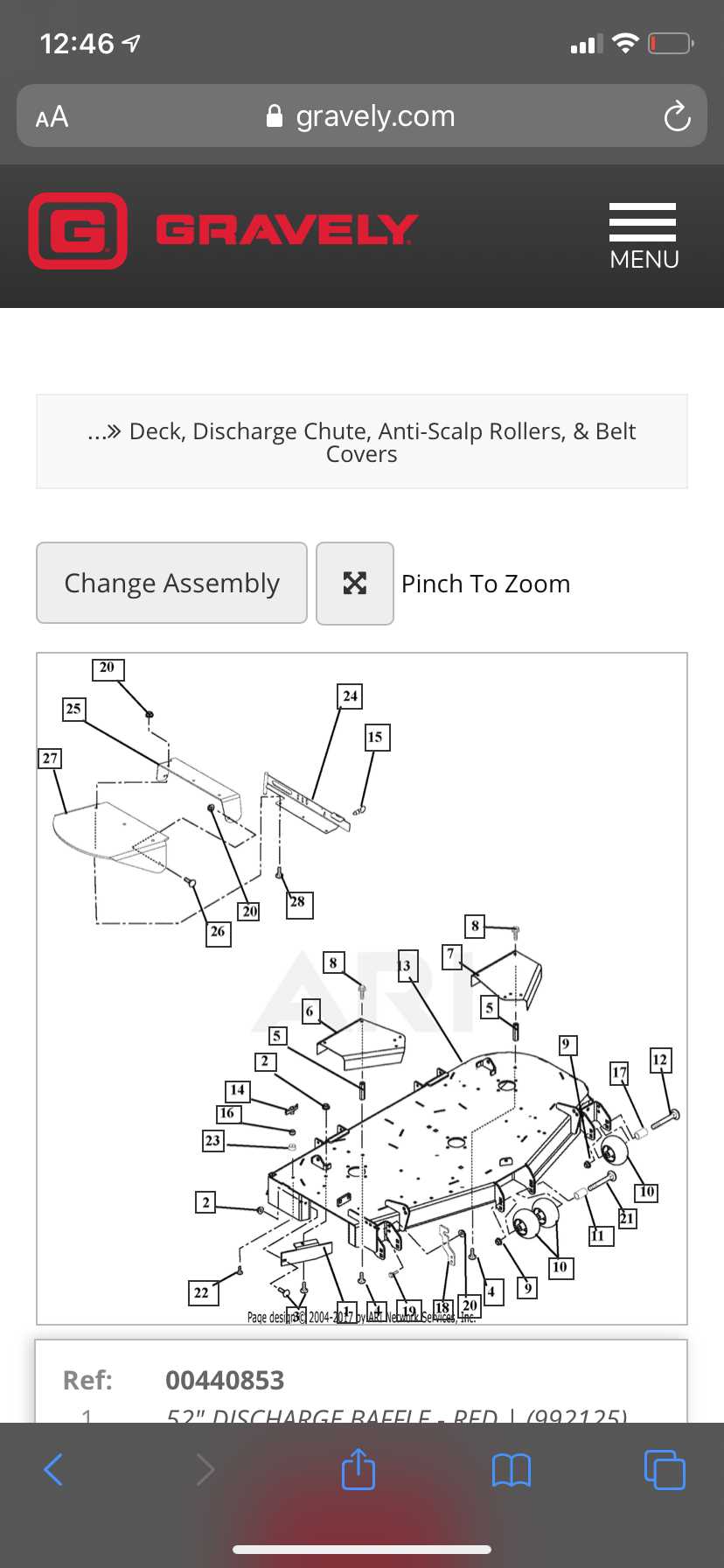

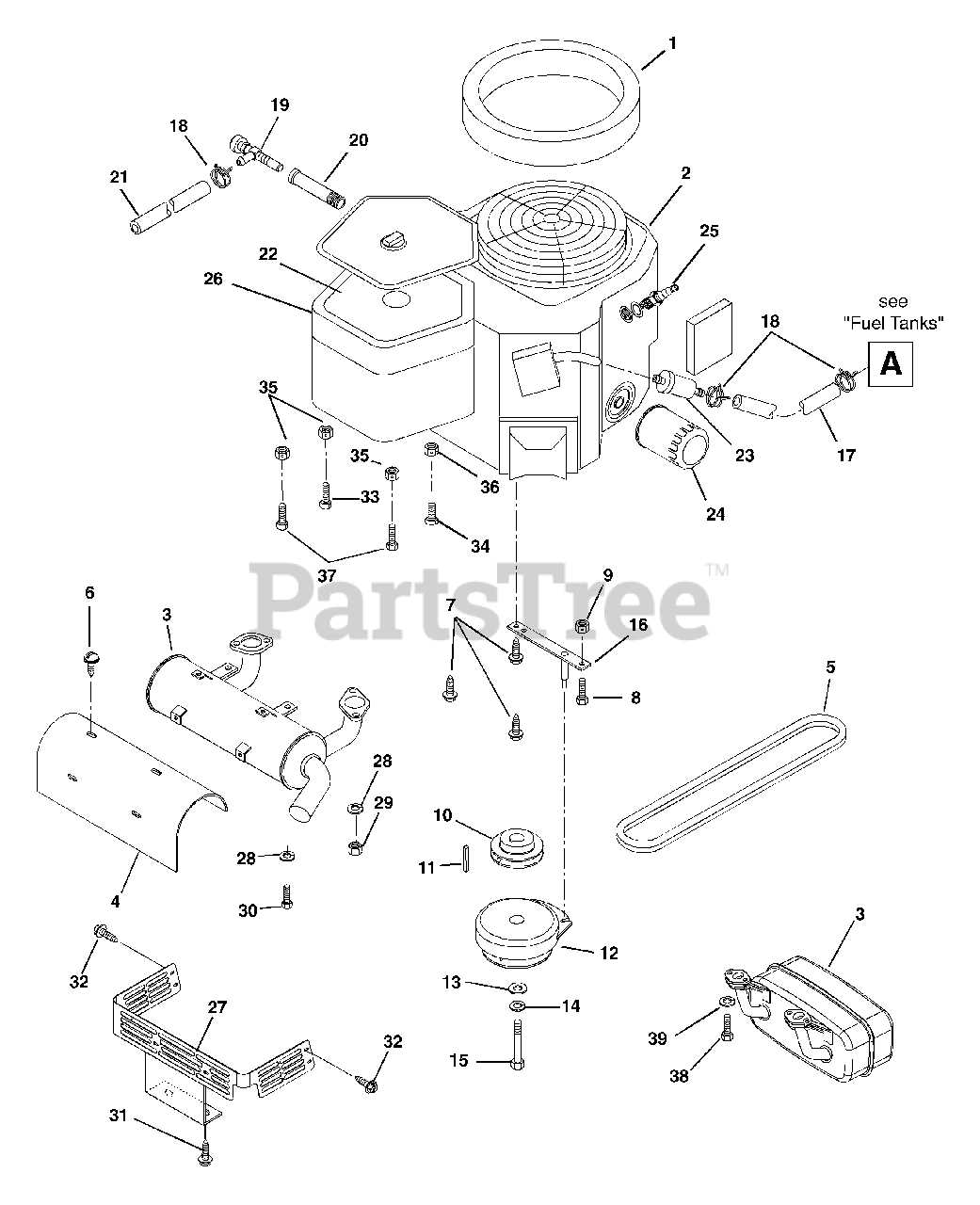

By examining a detailed visual representation, users can identify the specific roles and connections between parts. Such a guide enhances comprehension of assembly and facilitates easier navigation through the intricate system, making it easier to maintain or repair when needed.

Understanding the Machine Components

To effectively maintain and repair any complex machine, it’s essential to grasp how the individual elements interact within the system. This section breaks down the key components that drive the machinery, offering a comprehensive view of how each part plays a crucial role in overall performance. A deeper understanding of these internal systems ensures smoother operations and helps identify potential areas that require attention or improvement.

Key Functional Elements

Each segment of the machine is designed with a specific function in mind. From power transmission to control mechanisms, every part is interconnected, working seamlessly to achieve the desired output. Recognizing the individual contribution of each component can aid in troubleshooting and maintaining the machine’s longevity.

Efficient Maintenance and Care

Proper upkeep begins with an understanding of the critical components. By familiarizing yourself with their layout and function, regular inspections and minor repairs become more manageable. Recognizing wear and tear early on helps avoid more costly repairs and ensures the machinery operates efficiently for an extended period.

Key Components of the Machine

Understanding the essential components of a machine is fundamental to keeping it in optimal working condition. Each element plays a vital role in ensuring that the system functions efficiently. A thorough knowledge of these crucial pieces allows for better maintenance, troubleshooting, and overall longevity of the machine.

Among the key functional units, the engine serves as the heart, providing the necessary power for operation. Other components, such as the transmission system, ensure smooth movement, while control systems facilitate user interaction with the machine. Recognizing how these elements interact is important for making informed decisions regarding repairs and upgrades.

How to Use the Component Layout

Utilizing a visual layout of the system’s components can significantly simplify the maintenance and repair process. This resource helps users identify and understand the relationship between various elements, making it easier to locate specific parts when necessary. By referring to the layout, one can ensure the right steps are taken for troubleshooting, replacement, or adjustments.

Identifying Key Sections

The layout is usually organized by grouping related components, helping users focus on specific areas of interest. Identifying sections based on functionality allows for quicker access to the needed information and ensures that users do not miss any critical elements that could impact performance.

Step-by-Step Troubleshooting

When facing an issue, using the component layout to systematically trace potential problems can be incredibly effective. Start by referring to the sections most likely related to the malfunction, narrowing down the possible causes, and then moving through the remaining sections if needed. This methodical approach enhances problem-solving accuracy and reduces unnecessary delays.