For efficient pool operation, it is crucial to understand the inner workings of the control mechanism responsible for directing the flow of water. This system consists of several key elements that work together to maintain optimal performance and filtration. Recognizing each component’s role ensures smoother maintenance and repair tasks, preventing potential issues and extending the lifespan of the equipment.

Identifying and learning about each piece of this system allows pool owners to perform basic troubleshooting and improve their understanding of how water flow is managed. Familiarity with the layout and function of these components contributes to making informed decisions when it comes to repairs or upgrades.

In this guide, we will break down the essential elements of the control system, explaining their functions and how they interact. With this knowledge, you will be able to handle minor adjustments and recognize when professional assistance is required for more complex issues.

Understanding Pool Control System Components

In a well-maintained pool, the flow management mechanism plays a crucial role in ensuring smooth water circulation and filtration. This system is composed of several key components that each serve a specific purpose, helping to control the direction and pressure of the water. Familiarity with these elements helps users understand how water flow is adjusted during routine maintenance and repairs.

Main Components and Their Functions

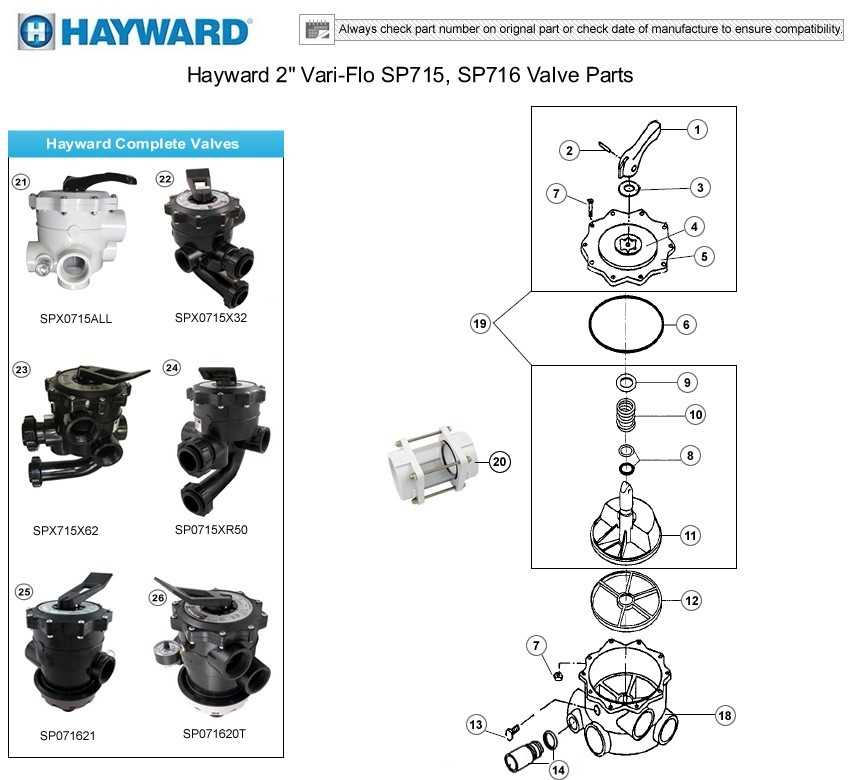

Each component in the flow control mechanism has a distinct function. The primary role of the system is to switch between different filtration settings, such as filtering, backwashing, and rinsing. Components like the rotating mechanism, seals, and control handles allow for easy adjustments to these settings, ensuring optimal pool cleanliness. Understanding how each part interacts within the system can help diagnose potential issues early, preventing costly repairs.

Common Problems and Maintenance Tips

Proper maintenance of the flow management system is essential for long-term functionality. Common problems, such as leaks or difficulty switching between settings, can often be traced back to worn seals or misaligned components. Regular cleaning, lubrication, and careful inspection of each part ensure the system operates smoothly. Identifying worn or damaged elements early on can prevent more serious breakdowns and improve the overall efficiency of the pool’s filtration process.

How to Identify Valve Parts and Functions

Understanding the individual components of your pool’s flow control system is essential for effective maintenance and troubleshooting. Each element within the system plays a specific role, from regulating water flow to switching between filtration modes. By recognizing and identifying these components, pool owners can ensure that everything is functioning correctly and address any potential issues before they become major problems.

Key Components to Look For

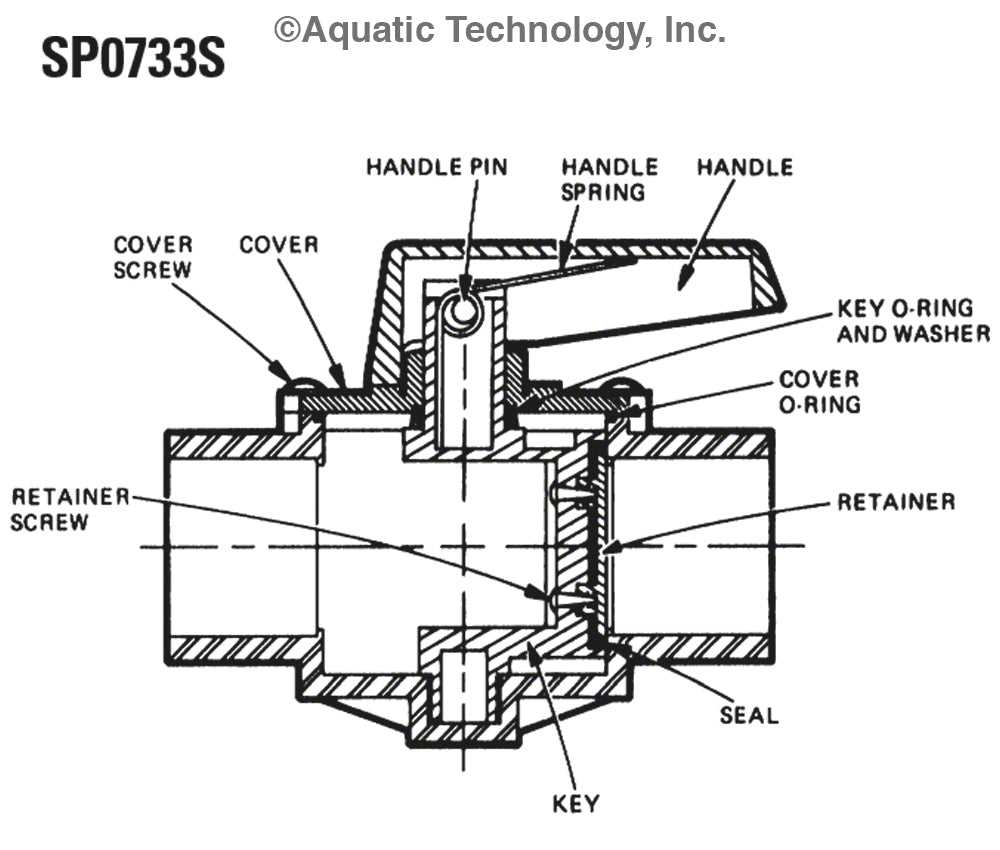

The control system consists of several crucial components, including the rotating handle, seals, and internal mechanisms responsible for adjusting the water flow. The rotating handle allows the user to switch between different filtration settings, while the seals prevent leaks and maintain pressure within the system. Understanding each component’s function helps to pinpoint issues such as leaks or difficulty switching settings.

How to Test Each Component

To test the functionality of each element, begin by inspecting the control handle for smooth movement. If there’s resistance or stiffness, it could indicate a buildup of debris or a worn internal part. Next, check the seals for any visible cracks or damage. Damaged seals often lead to leaks, so replacing them promptly is essential. Finally, observe the system’s performance during each filtration mode to ensure water is flowing as expected. If any settings fail to engage properly, it could signal a malfunction in the internal mechanisms.

Step-by-Step Guide to Valve Maintenance

Proper upkeep of your pool’s flow control system is vital for ensuring it operates efficiently and lasts longer. Regular maintenance prevents potential issues, such as leaks or reduced water flow, that can disrupt the entire filtration process. By following a clear, step-by-step approach, you can keep the system in top condition and avoid costly repairs down the line.

Start by turning off the pool’s pump to ensure safety while working on the system. Next, carefully remove the cover to access the internal components. Inspect the rotating mechanism and seals for any signs of wear or damage. If you notice any cracks, tears, or stiffness, replace the worn parts promptly to maintain proper functioning.

Once the internal components are inspected, clean the entire system to remove any debris or buildup. Use a soft brush to clear any dirt from the moving parts and lubricate the necessary sections to ensure smooth operation. Finally, reassemble the system and test the settings to confirm that the water flow is being properly managed. Regularly repeating this process will help prolong the life of the system and ensure optimal performance for your pool.