When it comes to ensuring the longevity and efficiency of agricultural machinery, having a clear understanding of its inner workings is crucial. Knowing where each component fits and how they interact can prevent costly mistakes during maintenance and repairs.

In this section, we will explore the intricate assembly of a popular piece of equipment, offering insight into how different parts are arranged. By following this guide, you will be able to identify each section’s purpose and make informed decisions when servicing the machine.

Having access to a detailed visual representation of the machine is invaluable for both beginners and experienced technicians. It simplifies the process of troubleshooting, ensuring that repairs are performed accurately and efficiently. Knowledge of each individual part and its function is key to maximizing performance and extending the machine’s lifespan.

Understanding the Assembly Overview

Knowing how the various components of a machine fit together and work in unison is essential for proper operation and maintenance. This section offers a comprehensive view of how the elements interact, ensuring that technicians and operators can make well-informed decisions when dealing with repairs or upgrades.

Visual Representation of the Machinery

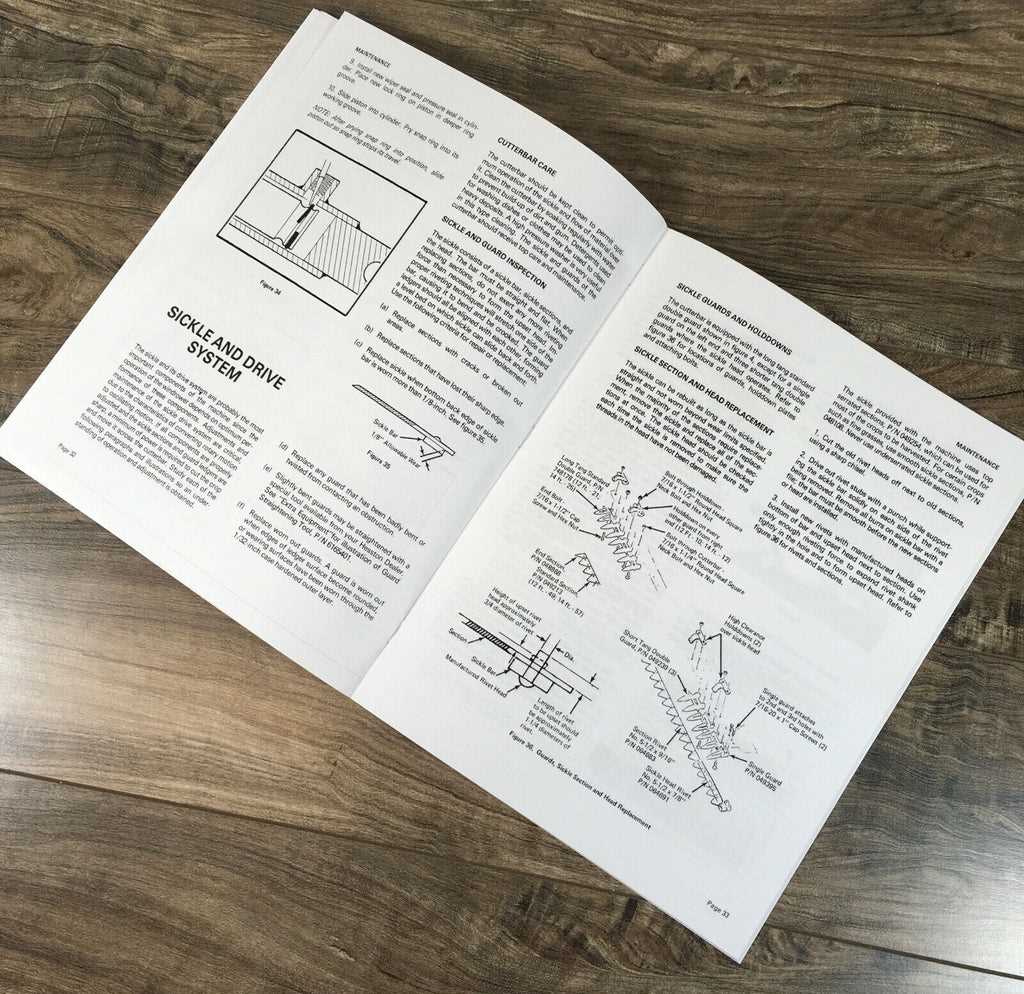

One of the most effective tools for understanding any machine’s structure is a clear, labeled illustration. These visuals provide a quick reference for locating and identifying individual sections. They help to highlight how each part contributes to the overall functionality, making it easier to diagnose issues and perform precise repairs.

Interpreting the Key Components

Each machine consists of a variety of sections, each serving a unique role. By studying these sections closely, operators can gain a deeper understanding of the device’s capabilities. A thorough grasp of each component’s function ensures smooth operation and simplifies troubleshooting when problems arise.

Essential Parts for Machine Maintenance

Proper upkeep of any machinery relies on understanding which components need regular attention. Regular maintenance ensures optimal performance and extends the machine’s lifespan. This section focuses on the key elements that require frequent inspection and servicing to avoid breakdowns and ensure smooth operation.

Some of the most crucial components for routine care include the drive system, the hydraulic components, and the cutting or harvesting mechanisms. These areas are prone to wear and tear, and keeping them in good condition is essential for uninterrupted functionality. Timely replacement of damaged or worn-out elements in these systems is critical to preventing more extensive damage.

Additionally, lubrication plays a vital role in minimizing friction between moving parts. Regularly checking fluid levels and ensuring that all gears and bearings are properly lubricated can significantly reduce the risk of mechanical failure.

How to Interpret the Machinery Illustration

Understanding a detailed visual guide is key to maintaining and repairing any complex machine. These illustrations provide a clear overview of how each section is constructed, showing how different components fit together and interact. Proper interpretation ensures that technicians can identify problems quickly and accurately.

Decoding the Visuals

Each section of the diagram typically includes labels, numbers, and arrows pointing to specific components. It’s important to familiarize yourself with these symbols, as they often represent unique parts or connections. By following the flow of the diagram, you can gain insight into the machine’s structure and pinpoint potential areas of concern.

Identifying Common Issues

Once you understand how the components are arranged, it’s easier to identify common wear-and-tear areas. The guide will often highlight the most critical parts that require frequent attention. Knowing where these parts are located allows for efficient troubleshooting and helps prevent unnecessary downtime.