When it comes to maintaining farming machinery, having a clear understanding of the individual components is crucial for effective repairs and overall machine longevity. Each piece of equipment relies on a network of parts working seamlessly together to perform specific tasks. Identifying these parts and their functions can significantly improve your ability to troubleshoot and maintain the machinery.

By exploring the layout of key components, you can gain a better understanding of how they interact and how to address potential issues. A well-detailed overview can make maintenance tasks more straightforward and help avoid costly repairs or downtime. Recognizing where each piece fits and how it functions in the bigger picture allows for more efficient operation.

Effective management of your machine ensures that it continues to deliver optimal performance throughout its lifespan. Whether you are a seasoned operator or a newcomer to agricultural equipment, having a comprehensive understanding of the machinery’s inner workings is essential for long-term success.

Understanding Hesston 3717 Tedder Components

Farming machinery consists of numerous essential elements that work together to achieve a smooth, efficient operation. Each component plays a specific role, contributing to the machine’s overall functionality. Knowing these elements and how they interconnect is vital for successful maintenance and troubleshooting.

Typically, agricultural equipment incorporates rotating arms, gears, and drive systems that interact to perform their designated tasks. Each of these elements must be carefully aligned and maintained to ensure the machinery operates at peak efficiency. Understanding where each piece fits within the machine’s framework helps pinpoint issues quickly and streamline repairs.

Regular inspections and a solid understanding of each component’s function enable operators to identify wear and tear before it leads to more significant problems. In turn, this can reduce downtime and increase productivity on the field. Whether for daily operations or emergency repairs, a clear grasp of the equipment’s makeup is essential for maintaining consistent performance.

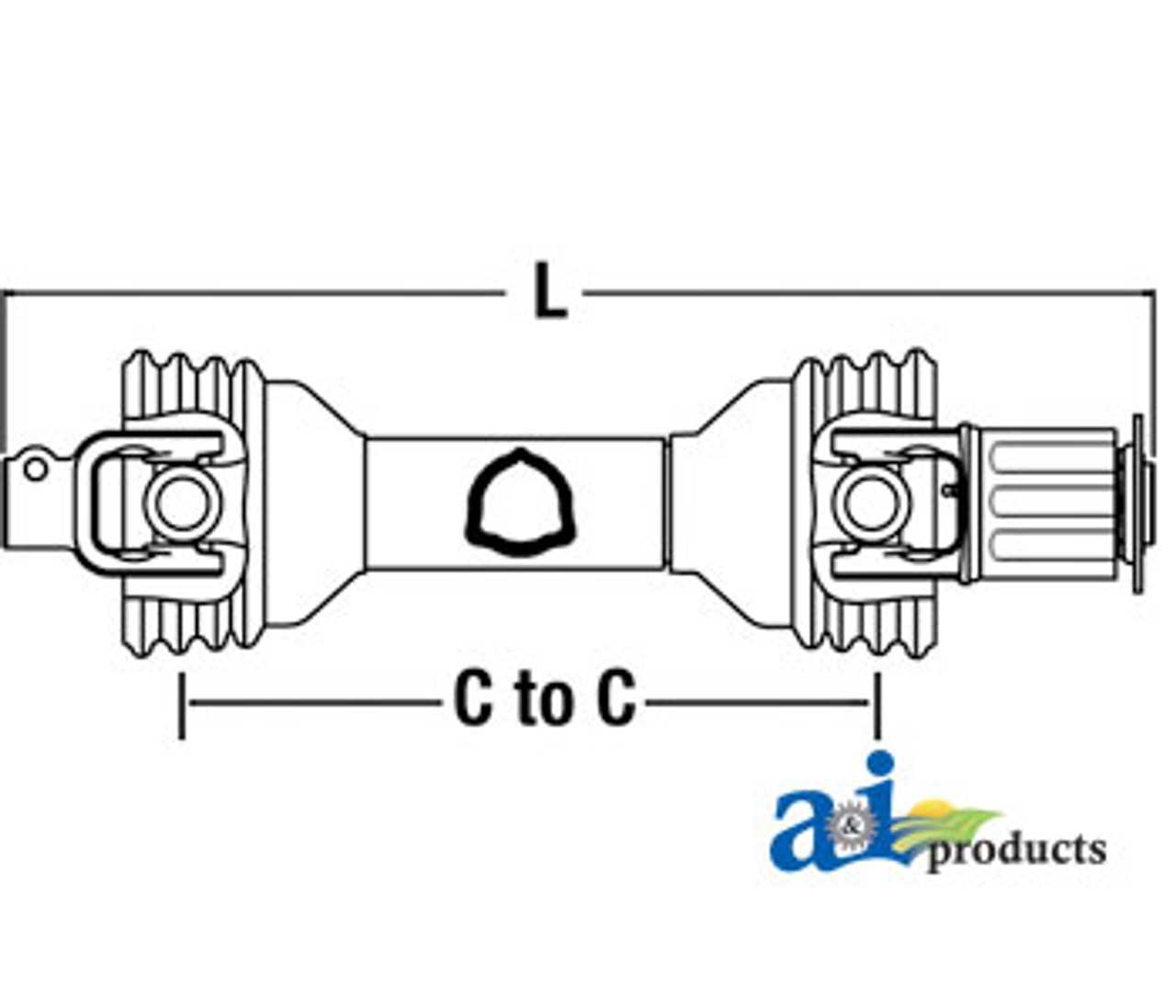

How to Read the Parts Diagram

Understanding the layout of a machine’s components is essential for effective troubleshooting and repairs. A detailed illustration showing the different elements of the equipment can help users identify each piece’s location and its function. By learning to read this visual guide, operators can more easily locate issues, order replacements, or conduct necessary maintenance tasks.

Identifying Key Elements

Start by identifying the main groups of components, such as the drivetrain or the hydraulic system. These sections will often be highlighted or labeled to help users differentiate between the various parts. Understanding these groupings is crucial because it allows you to focus on specific areas when diagnosing a problem or performing maintenance.

Understanding Part Numbers and Labels

Each component is typically assigned a unique identifier or part number, which makes it easier to find exact replacements. Labels and arrows in the diagram guide you through the layout, showing where each part connects or interfaces with other elements. Becoming familiar with these references helps streamline the maintenance process and ensures you have the right parts when needed.

Common Maintenance Tips for Hesston 3717

Regular upkeep of agricultural machinery ensures longevity, optimal performance, and smooth operation. It involves basic tasks that can prevent costly repairs and downtime. Consistent inspection and care of key components should be a priority to maintain efficiency during each use. Below are some essential practices to follow to keep your equipment in top condition throughout its service life.

1. Lubrication and Greasing

One of the most important maintenance steps involves keeping moving parts properly lubricated. This minimizes friction, prevents wear, and reduces the risk of malfunction. Make sure to regularly apply grease to the designated grease points as outlined in the user manual. Pay extra attention to components that endure heavy loads or constant movement, such as bearings and gears.

2. Inspection of Belts and Cables

Examine all belts and cables for signs of wear, cracking, or fraying. Damaged belts can lead to operational failures or inefficiency, while compromised cables may cause control issues. Ensure that belts are correctly tensioned to avoid slipping or over-stretching, and replace any that show significant signs of damage.

Regular monitoring of these components is key to preventing unexpected breakdowns and ensuring smooth operations throughout the season. Be proactive in replacing parts before they fail completely to avoid interruptions to your work schedule.

3. Cleaning After Use

Debris, dirt, and plant matter can accumulate on the machine during operation. These particles can interfere with the machine’s function, leading to overheating or clogging. After each use, thoroughly clean the equipment, especially areas prone to buildup, such as the drive system and fan mechanisms. Using compressed air or a pressure washer can help remove stubborn residue.

By adhering to these simple but effective maintenance tasks, you can extend the lifespan of your machinery and improve its overall performance.