When working with agricultural equipment, knowing how each part functions and connects is essential for smooth operation and maintenance. Every machine consists of several key elements that work together to ensure its effectiveness and longevity. Recognizing these components and understanding their roles can help users optimize performance and reduce the likelihood of costly repairs.

Illustrations and detailed manuals serve as valuable tools for identifying individual parts and understanding their placement. A clear representation of these components enables operators to troubleshoot, maintain, and replace parts when necessary. This knowledge is crucial for keeping the equipment in top working condition and preventing unexpected breakdowns during critical tasks.

Understanding the Components of Hesston 530 Baler

Every piece of machinery is made up of various crucial elements that each serve a specific function. Knowing how these elements work together helps in ensuring smooth operation and timely maintenance. Each component contributes to the overall efficiency of the machine, from the feed system to the output mechanism. Familiarity with these key parts makes it easier to spot potential issues before they affect performance.

Mechanical systems such as the drive, feed rollers, and collection mechanisms are integral to the success of any agricultural tool. These parts must be regularly checked to maintain peak productivity. Additionally, components like clutches and hydraulic systems play significant roles in controlling the machine’s movement and function. Understanding the interaction between these various elements allows for better troubleshooting and more informed maintenance practices.

Identifying Key Parts in the Diagram

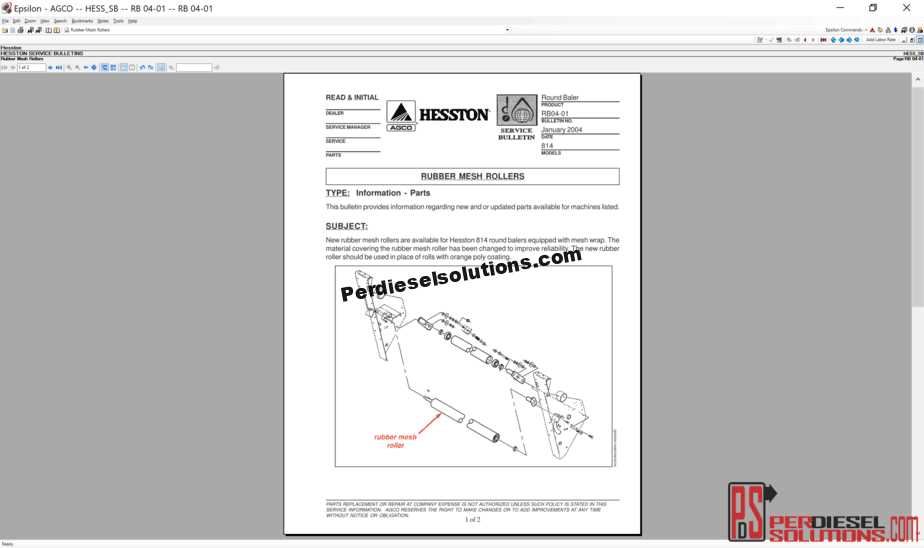

Understanding the key components depicted in a machine schematic is essential for effective maintenance and repair. Recognizing the major elements allows for easier troubleshooting and ensures that all parts are properly accounted for during any work process. In this section, we will break down the primary components to focus on and provide guidance on their function and positioning within the system.

Primary Components to Focus On

The most critical elements of the system can be identified by looking for larger, more central components. These often serve as the main operational parts that facilitate the overall function. Some of these include mechanisms that enable motion, control, or adjustment, which are crucial for the smooth running of the machine.

Understanding the Interactions

Once the key parts are identified, it’s important to understand how they interact. Proper coordination between different components ensures efficiency and prevents breakdowns. Pay particular attention to the connections and how power or material flows through the system, as these areas are often where failures or malfunctions occur.

How to Maintain Machine Components

Proper maintenance of critical machine elements is vital for ensuring longevity and peak performance. Regular inspection and care can prevent unexpected malfunctions and reduce the need for costly repairs. This section outlines key steps to follow in maintaining the most important components, ensuring your equipment operates smoothly over time.

Regular Inspections and Lubrication

Routine checks are essential for identifying wear and tear before they lead to bigger issues. Ensure that moving parts are regularly lubricated to reduce friction and extend their lifespan. Inspect the gears, belts, and other mechanical parts for signs of damage or excessive wear.

Cleaning and Adjustments

Keep all components free from dirt, debris, and buildup that can hinder their function. Clean the internal parts thoroughly and adjust settings as needed to ensure proper alignment and operation. Proper cleaning and calibration can drastically improve efficiency and prevent premature breakdowns.