Every complex tool consists of various elements working in harmony to ensure smooth operation. Recognizing each of these components is essential for proper use and maintenance. In this section, we will explore the essential elements that make up the device, giving you a clearer understanding of how it functions and how each part contributes to its overall performance.

Proper knowledge of internal mechanisms can greatly improve your efficiency when handling the tool. Familiarizing yourself with the structure of the equipment helps in troubleshooting, identifying wear and tear, and performing maintenance tasks. Whether you’re assembling or disassembling the tool, understanding the key components will make these processes more straightforward.

By the end of this guide, you’ll gain a comprehensive overview of the various essential parts and their respective functions. This knowledge will enable you to make informed decisions about repair, replacement, and overall care for the tool, enhancing its longevity and reliability.

Understanding the Tool’s Internal Components

Every high-performance tool is made up of multiple intricate elements that work together seamlessly. A thorough understanding of these individual components is crucial for anyone looking to maximize their tool’s efficiency and longevity. By familiarizing yourself with each part, you will gain a deeper insight into its functionality and how it contributes to the overall operation.

Key elements of any mechanical system often include drive mechanisms, safety features, and user interface components. Each of these plays a specific role in ensuring smooth operation and reducing the likelihood of malfunctions. Recognizing the location and purpose of each piece makes troubleshooting easier and allows for faster identification of issues.

Proper maintenance of these components is vital for preserving the tool’s functionality. Regular inspections and replacements of worn parts can prevent costly repairs and extend the device’s useful life. Understanding the layout and construction of these internal elements equips you with the knowledge needed to perform basic repairs and ensure optimal performance over time.

Detailed Breakdown of the Tool’s Components

Every tool comprises several crucial elements, each designed to perform a specific function. Understanding the intricate relationship between these individual parts helps in identifying potential issues and ensures proper usage and maintenance. In this section, we will delve into a detailed analysis of each major component and its role in the overall functionality of the device.

Drive Mechanism and Power System

The drive mechanism is at the heart of any tool, converting energy into the motion required for operation. It typically includes gears, motors, and power transfer elements that ensure smooth and efficient movement. A well-maintained drive system minimizes friction and wear, contributing to the tool’s longevity and performance.

Safety and Control Features

Safety is paramount when working with mechanical tools. The control features and safety mechanisms are designed to prevent accidents and malfunctions. These components include trigger systems, locking mechanisms, and protective shields that allow for safe operation, making it essential to understand their function and ensure they are in optimal condition.

How to Identify the Tool’s Components

Recognizing and identifying each component within a mechanical tool is essential for efficient operation and effective troubleshooting. Knowing where each part fits and how it functions helps prevent errors and makes maintenance easier. Here are some key steps to help you identify the internal elements of your tool.

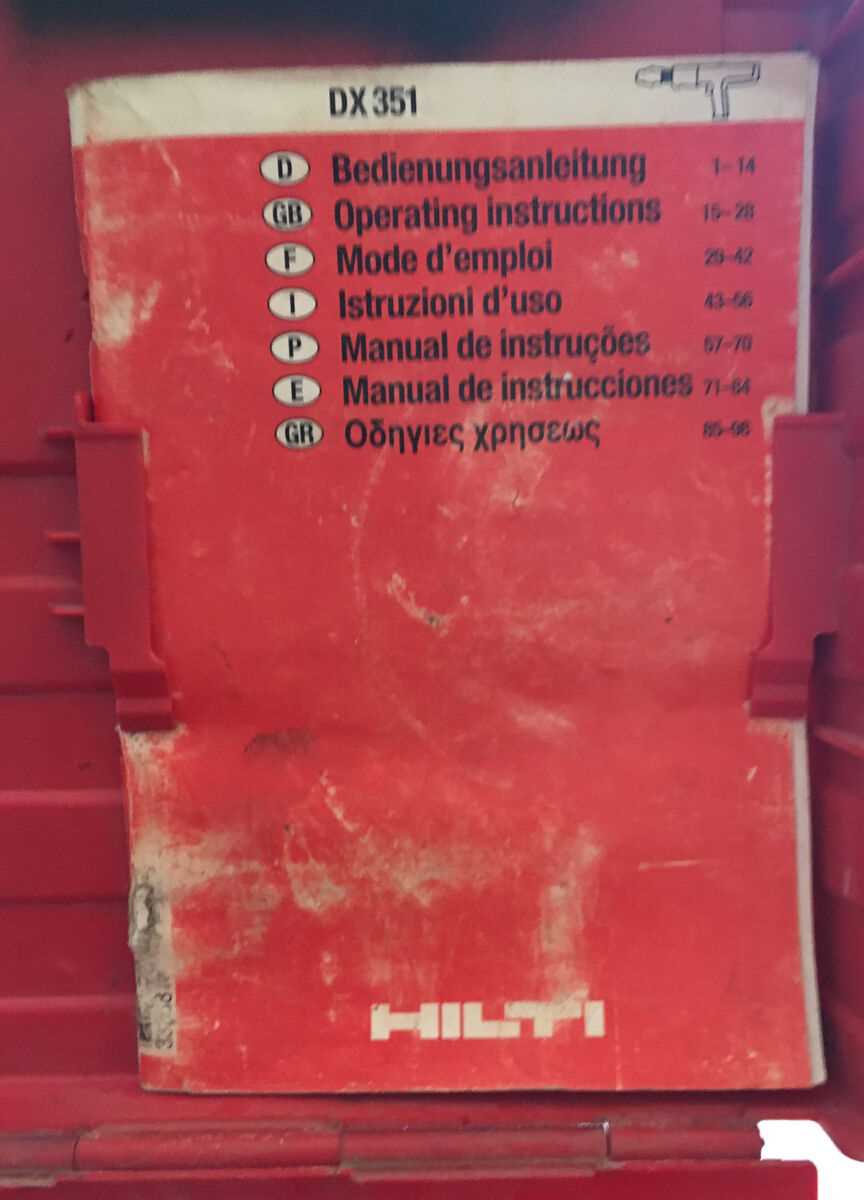

- Consult the User Manual – Always refer to the official user manual for a comprehensive overview of the components. This will provide detailed information on each part, including its location and function.

- Examine the Tool’s Assembly – Carefully disassemble the tool to get a clear view of all its parts. Take note of how each component connects with others to understand their individual roles.

- Use Visual Aids – Visual diagrams and exploded views can be extremely helpful in pinpointing each element. These resources are often available online or in repair guides.

When identifying parts, always make sure to check for any markings or labels on the components, as these can provide valuable information regarding their specifications and model compatibility.