When it comes to power tools, knowing the key components and how they fit together is essential for smooth operation. Every machine has a unique structure, and familiarizing yourself with it can make troubleshooting and repairs much easier. Understanding the essential elements of your device allows you to keep it in optimal condition, ensuring longevity and reliability.

Proper maintenance starts with knowing the different components and their functions. With a clear overview of how each piece interacts with the others, you can quickly identify potential issues before they become major problems. Whether you’re performing routine upkeep or tackling a specific malfunction, having a detailed understanding of the tool’s structure is vital.

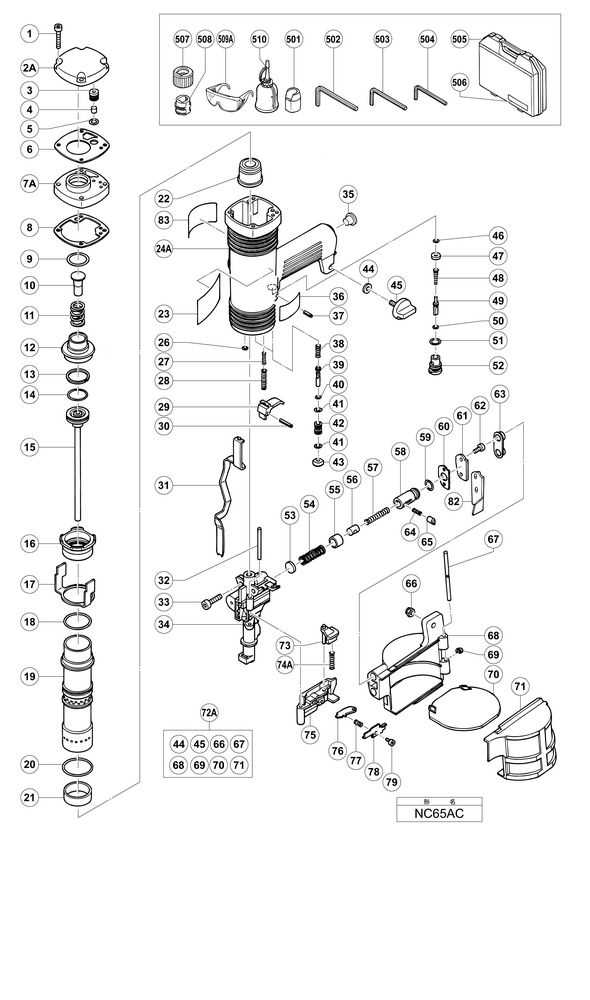

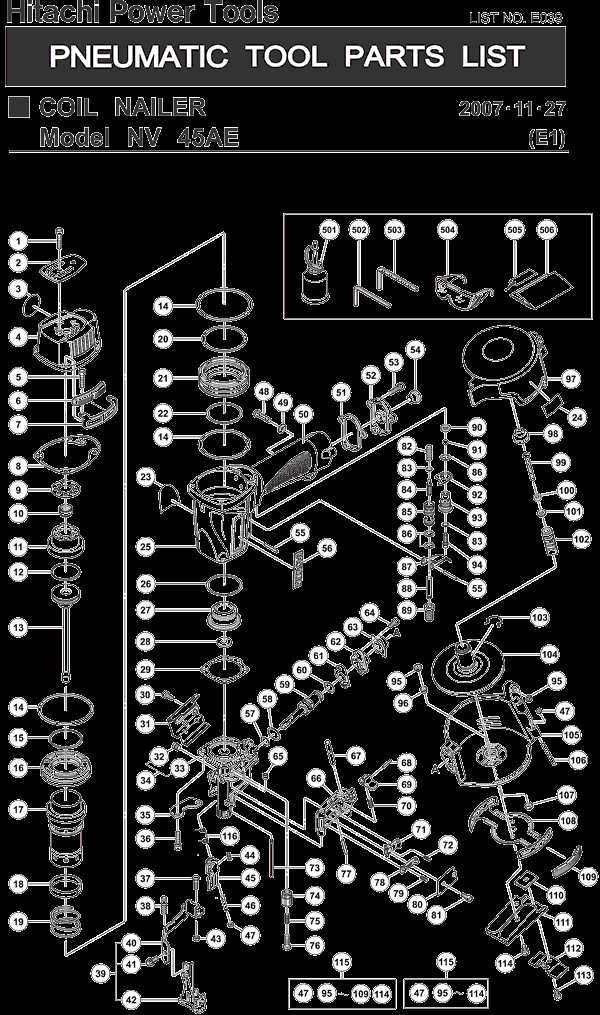

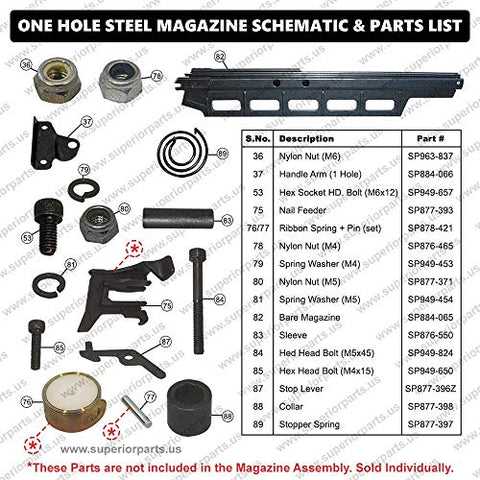

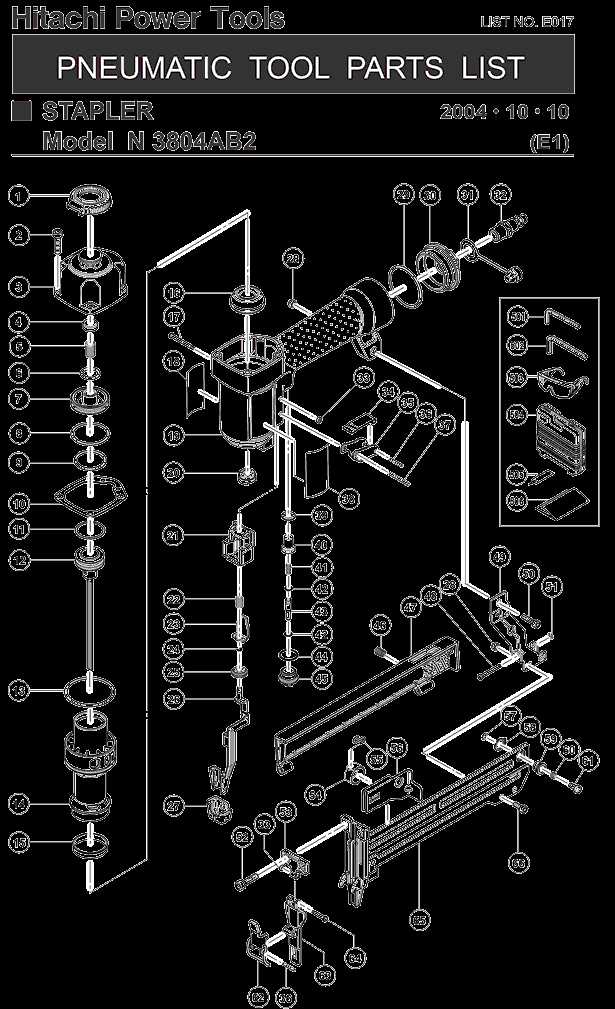

By referring to detailed illustrations and guides, you can navigate through each segment confidently. These resources help in recognizing each part’s role and can serve as a useful reference during repairs or adjustments. Mastering the mechanics of your tool will not only save time but also improve its overall performance.

Understanding Hitachi Nail Gun Components

Every tool has a collection of vital elements that work together to ensure efficiency and performance. By recognizing the different sections within your device, you can grasp how each part contributes to its overall function. This knowledge is not only valuable for troubleshooting but also for ensuring smooth and continuous operation.

Key Elements and Their Functions

Each component in your device plays a specific role, from providing power to delivering precision. These components work in harmony to create the force needed for each task. Identifying each element’s purpose helps understand how they interact and why certain parts may need attention during maintenance or repair.

Common Issues to Look Out For

Understanding the layout of your tool also prepares you for common issues that may arise. Familiarity with the setup makes it easier to spot worn-out or malfunctioning sections, allowing for quicker repairs and minimizing downtime. Regular inspection and awareness of each component’s condition can keep your device in top working order.

How to Identify Parts in a Diagram

When working with any complex tool, understanding how to navigate its technical illustrations is key to proper maintenance and repair. These visuals provide a detailed look at how each element fits into the overall structure. Recognizing the different sections helps you pinpoint potential issues and make necessary adjustments with ease.

Steps to Read and Interpret Illustrations

The first step is familiarizing yourself with the legend or key, which often labels each component. From there, you can begin tracing the connections between parts, understanding how they function together. These diagrams are meant to be straightforward, so by following the lines and labels, you can easily identify each section and its role within the system.

Common Symbols and Notations

Each diagram uses symbols and notations to represent different components. Understanding these common markings is crucial for accurately interpreting the visual guide. Once you’re familiar with these symbols, you can quickly identify any part you need to inspect or replace, making repairs and maintenance much more efficient.

Common Issues and Maintenance Tips

Regular use of any mechanical tool can lead to wear and tear, which in turn can cause malfunctions or reduce efficiency. Understanding the common problems that arise in these devices is essential for timely repairs and ongoing performance. Simple maintenance practices can go a long way in preventing these issues from escalating into major problems.

One of the most frequent issues is the buildup of dirt or debris, which can clog or hinder the movement of moving parts. Regularly cleaning the tool and inspecting for blockages will help maintain its smooth operation. Additionally, checking for any loose connections or worn-out components can prevent unexpected breakdowns during use.

Proper lubrication is also key to ensuring the longevity of your tool. Dry or insufficiently lubricated sections can cause friction, leading to premature wear. By following a routine maintenance schedule and staying alert to common malfunctions, you can extend the life of your equipment and keep it functioning at its best.