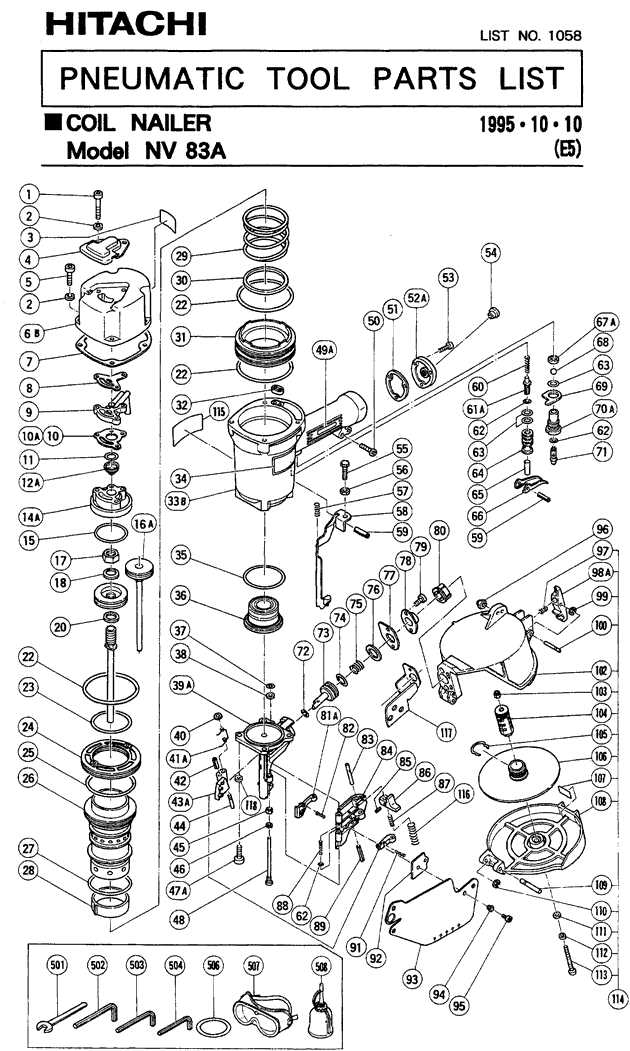

Every complex tool is made up of various essential elements that work together to ensure its optimal functionality. To maintain and repair such equipment, a clear understanding of its individual parts is crucial. This section focuses on providing a detailed view of how each component interacts within the tool’s structure.

Knowing the layout and function of each piece allows users to troubleshoot more effectively and perform repairs with confidence. Whether it’s replacing a worn-out component or identifying a malfunction, having a visual guide makes the process simpler and faster.

Efficient use of these resources will help you save time and reduce unnecessary costs, ensuring your tool remains in top condition for longer periods of use. Understanding each part’s role also empowers you to make informed decisions regarding maintenance and replacement.

Understanding Tool Component Breakdown

When working with any mechanical device, having a clear overview of its internal structure is essential for effective maintenance and repair. A comprehensive representation of a tool’s individual elements allows users to visualize the connection between different components and understand their respective functions. This clarity not only aids in repairs but also enhances the overall efficiency of usage.

Familiarizing yourself with how each segment fits together ensures that you can quickly identify issues and resolve them without unnecessary disassembly or confusion. A well-organized visual reference becomes invaluable, as it acts as a guide when handling the tool during repairs, adjustments, or replacement of damaged parts.

By mastering this tool’s structure, you gain the ability to address problems independently, saving both time and costs associated with professional repairs. Recognizing individual elements and their roles also fosters better long-term care, ensuring reliable operation even after extensive use.

Key Components of the Tool

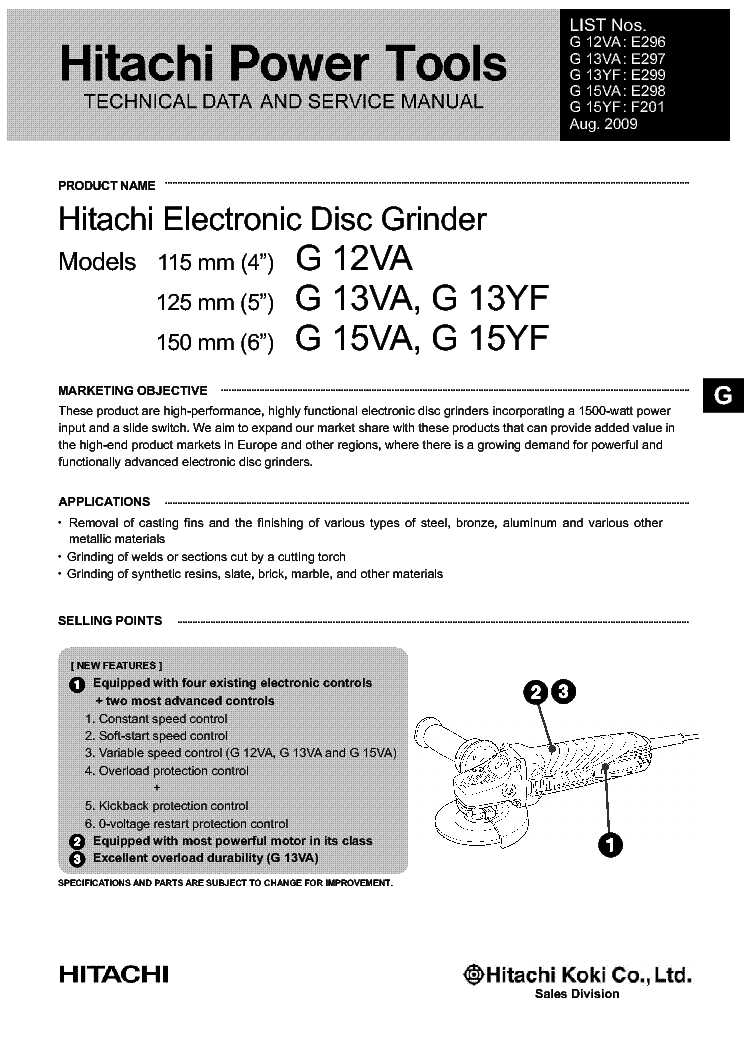

Understanding the key elements of a tool is essential for maximizing its performance and ensuring its longevity. Each component plays a specific role in the overall functionality, and knowing what each part does can make it easier to maintain and troubleshoot. By focusing on the main components, users can achieve smoother operation and faster repairs when needed.

Main Drive Mechanism

The drive mechanism is at the heart of the tool’s operation, providing the necessary force to drive the tool’s functions. This component is crucial for its efficiency, as it directly impacts power transfer and performance. Regular maintenance of the drive system ensures that the tool continues to work seamlessly over time.

Safety and Control Features

Safety is paramount when using any power tool. Control features, including safety mechanisms, are designed to protect both the user and the device. These parts are essential for preventing accidents and ensuring that the tool is used within safe operational limits, enhancing both reliability and user confidence.

How to Use the Parts Diagram Effectively

Utilizing a detailed visual guide of a tool’s structure is essential for accurate repairs and maintenance. It allows users to identify components, understand their interconnections, and locate any issues quickly. To maximize the usefulness of this reference, it’s important to approach it with a methodical strategy that ensures both efficiency and precision during repairs.

Start by carefully reviewing the entire illustration to familiarize yourself with the layout. Identifying the key components and their positions within the device helps establish a clear understanding of how the system operates as a whole. Once you are familiar with the tool’s anatomy, pinpoint the specific area of concern based on the symptoms of the malfunction.

As you follow the guide, make sure to reference the numbers or labels associated with each part. This helps when searching for replacements or troubleshooting. Always cross-check these visual references with the tool in hand, ensuring you are working on the correct components.