Understanding the internal structure of complex machinery is essential for effective maintenance and repair. Every element plays a specific role in the overall operation, ensuring smooth functionality and efficiency. Proper knowledge of these components can lead to quicker diagnostics and more informed decision-making when issues arise.

The detailed layout of all interconnected parts allows users to grasp how each piece contributes to the system’s performance. Recognizing the function of each part helps in troubleshooting and optimizing the machinery for peak performance.

Efficient maintenance and precise repairs are only possible when one understands the intricate relationships between each element. This guide offers a clear representation to facilitate a deeper understanding of how the system works and what needs attention during servicing.

Understanding the HL94K Components

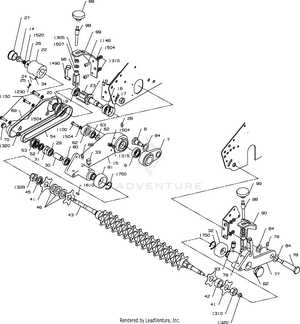

In any mechanical system, a deep understanding of its individual elements is crucial for effective operation and troubleshooting. Each component has a unique role, contributing to the overall efficiency and reliability of the system. By studying the structure and function of these elements, users can gain valuable insights into how the entire system performs under different conditions.

Exploring the Key Elements

The system is built upon several core elements that work in tandem to ensure smooth operation. These components are designed to interact with each other seamlessly, with each serving a specific function that supports the overall objective. Recognizing these relationships is vital for both routine maintenance and addressing potential issues as they arise.

How Components Influence Performance

Each individual element affects the performance and longevity of the system. Understanding how these parts function together allows users to make informed decisions when optimizing or repairing the equipment. Proper management of each component ensures the system operates at peak capacity, extending its lifespan and improving its reliability over time.

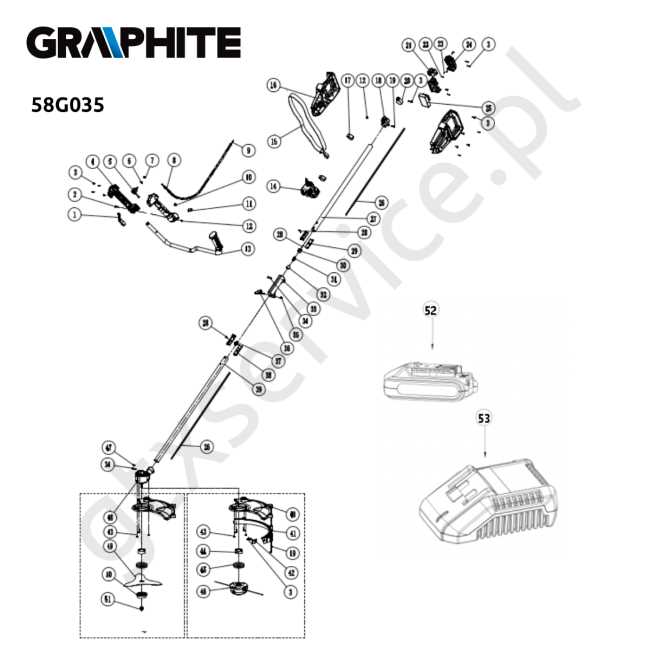

Identifying Key Parts in the Diagram

Recognizing the essential components of a mechanical system is an important step in understanding its overall functionality. Each piece plays a critical role, and being able to identify them ensures that users can navigate the system with confidence. Knowing the key elements helps in troubleshooting, maintenance, and ensuring optimal performance.

To effectively pinpoint these components, it’s necessary to focus on the main structures that contribute to the system’s operation. These include the central units responsible for controlling the process and the smaller elements that support functionality. Familiarity with these parts makes it easier to diagnose potential issues and carry out repairs as needed.

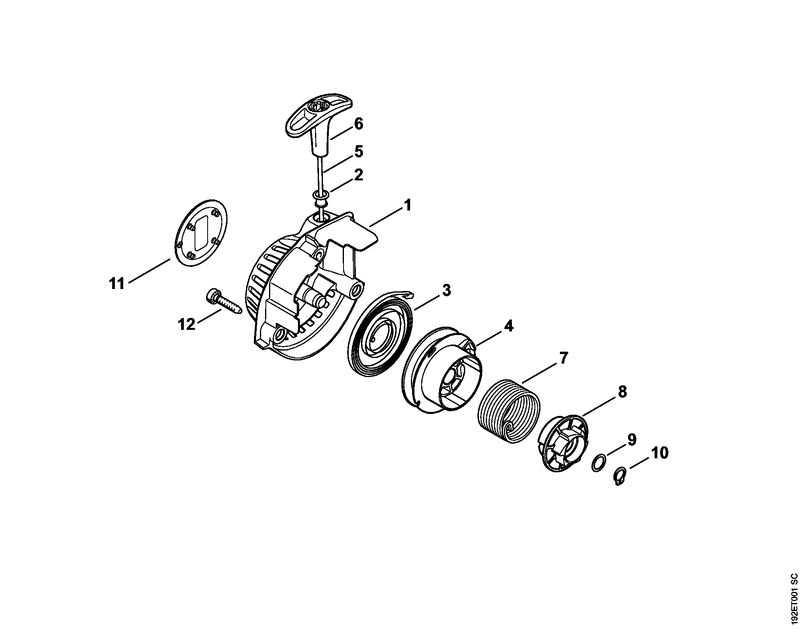

How the HL94K Components Work Together

The functionality of any system depends on how its individual elements interact with each other. A well-designed machine relies on the harmonious operation of its various components, each contributing to the overall process. Understanding how these elements collaborate ensures better management, troubleshooting, and optimization.

Collaboration of Core Units

The primary units in the system work in unison to control and regulate the operation. Each core element performs a specific task, while simultaneously supporting the functions of other parts. This interaction creates a balanced workflow, allowing the system to operate smoothly without disruptions.

Supporting Components and Their Role

Smaller components play a crucial role in supporting the larger units. Though they may not have as prominent a function, they provide necessary assistance that enhances the overall performance. By ensuring that all parts are functioning properly, users can maintain a high level of efficiency and extend the life of the system. Efficient coordination of all elements is key to achieving optimal results.