When working with complex kitchen machinery, it’s essential to have a clear understanding of its internal components. Knowing how each piece functions ensures smooth operation and efficient performance. Whether you’re troubleshooting an issue or performing maintenance, familiarizing yourself with the structure of your equipment can prevent unnecessary breakdowns.

Identifying individual components plays a crucial role in ensuring that your device runs at its best. Each part has a specific function, and recognizing them helps you manage repairs and replacements effectively. In this section, we’ll guide you through the key elements that make up your appliance.

Having a solid grasp of the internal structure allows you to maintain your equipment properly and extend its lifespan. By being proactive about upkeep, you can avoid costly repairs and enhance the longevity of your machine.

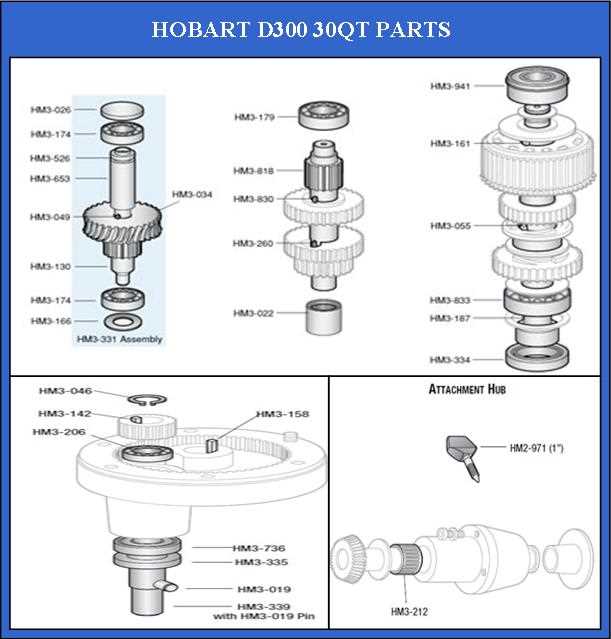

Understanding Hobart Mixer Components

The inner workings of a professional kitchen machine involve a variety of key elements that contribute to its efficiency. Each component plays a specific role in ensuring smooth operation, from processing ingredients to maintaining consistent performance. These pieces work together to create a seamless experience, making it essential to recognize their functions and interrelationships.

The central unit is the powerhouse, responsible for driving the system, while auxiliary parts support functionality, such as attachments for different tasks. The rotating mechanism and mixing tools enable thorough incorporation of ingredients, while protective features ensure safe use during high-demand tasks. Understanding each element’s contribution can improve maintenance and operational efficiency.

Careful attention to the assembly allows for optimal performance, as well as preventing unnecessary wear and tear. Regular checks and timely replacements of worn-out components help maintain the longevity of the equipment, ensuring it remains reliable for long-term use in demanding environments.

Key Parts of Hobart Mixer Explained

The essential components include:

- Drive System – This mechanism powers the machine and enables movement of different parts, such as the mixing tools and bowl lifts.

- Mixing Attachments – These are interchangeable tools, such as whisks, paddles, and hooks, used for different preparation tasks like kneading, beating, or stirring.

- Speed Control – A system that allows the user to adjust the rotation speed, providing flexibility for various recipes and tasks.

- Bowl Support – The frame or bracket that holds the mixing bowl securely in place during operation.

- Motor – The engine that drives the movement of the machine’s internal components, ensuring powerful operation for heavy-duty mixing tasks.

Each element plays a critical role in ensuring that the machine functions smoothly. Regular inspection and understanding of how these parts interact can prolong the lifespan of the equipment and ensure its effectiveness in a high-volume kitchen environment.

How to Identify and Replace Parts

Recognizing when a component needs replacement and knowing how to properly replace it is essential for maintaining the functionality of any professional kitchen equipment. By understanding the key components and their roles, users can more easily identify issues that may arise over time. This process ensures that the machine continues to operate at its peak performance and avoids unnecessary downtime.

The first step in identifying a faulty part is observing any irregularities in the operation, such as unusual noises, reduced efficiency, or failure to operate. Once the issue is pinpointed, it’s important to examine the component for visible wear or damage, such as cracks, rust, or broken parts.

To replace a damaged component:

- Turn off the machine and disconnect it from the power source to ensure safety during maintenance.

- Access the affected part by removing any protective covers or panels as necessary.

- Remove the faulty component by unscrewing or unfastening it from its position.

- Install the new component by securing it in place, ensuring it is properly aligned with the system.

- Test the machine to verify that the replacement part is functioning correctly.

Remember, using high-quality replacement components and following the manufacturer’s instructions ensures the longevity and efficiency of the equipment. Regular inspections and prompt replacement of damaged items will help prevent more significant issues down the line.