When dealing with heavy-duty machinery designed to handle large, tough materials, it’s essential to have a clear understanding of the different elements that make up the equipment. Proper knowledge of these components allows for easier troubleshooting, maintenance, and efficient operation. Each piece is carefully designed to work in tandem with others, ensuring optimal performance over time.

The structure of such machines often includes various mechanical parts that are interdependent. Identifying these components and understanding their arrangement can help operators spot potential issues before they become serious problems. Familiarity with these internal structures aids in making informed decisions when it comes to repairs or replacements, ultimately extending the lifespan of the machinery.

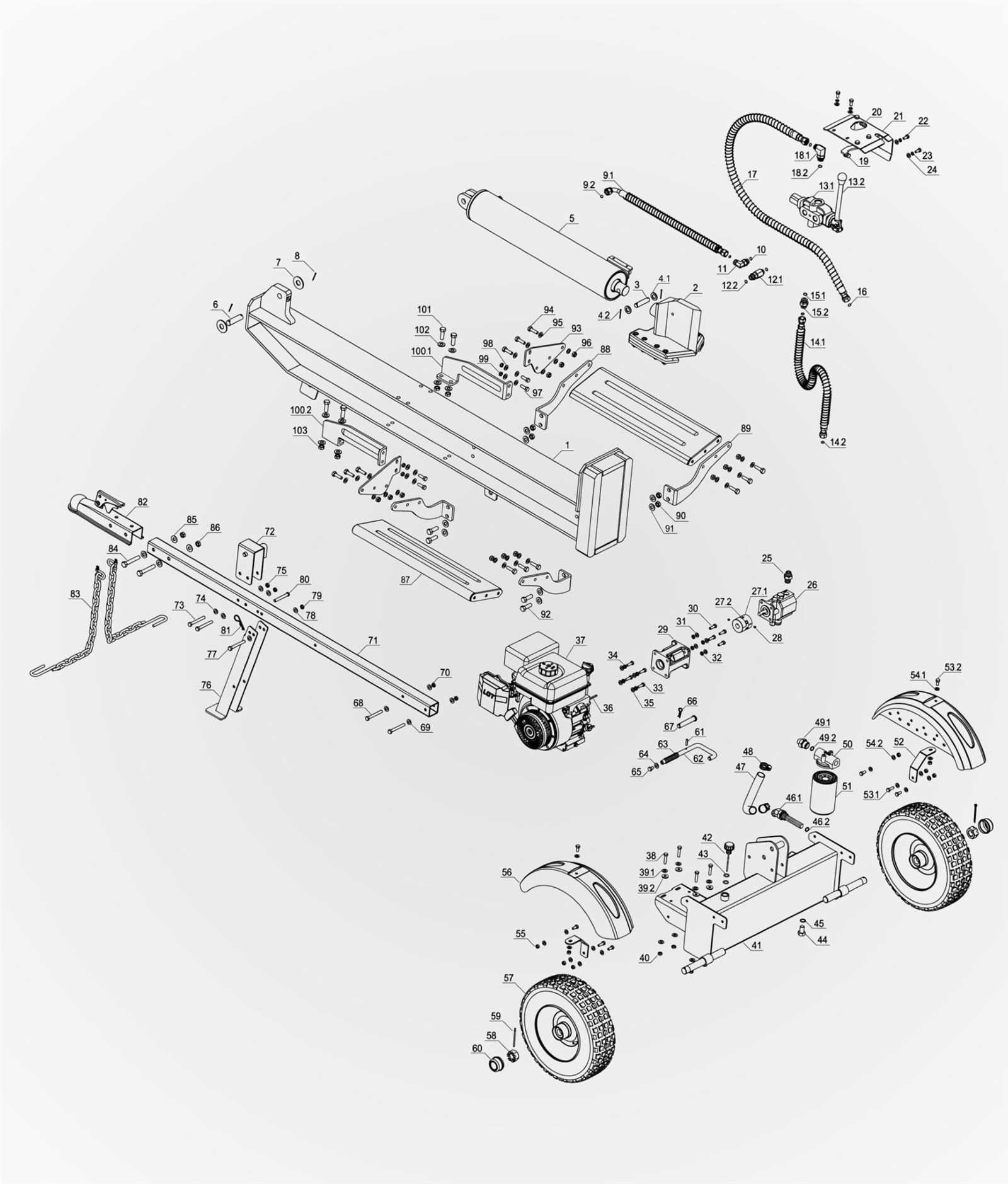

Visualization of the configuration is key to navigating through the assembly. A detailed illustration of the layout provides a quick reference for identifying each segment and its specific role. This kind of visual guide simplifies the process for both new and experienced users, ensuring they can maintain and operate the machinery safely and effectively.

Understanding Machine Components

Proper functioning of any heavy-duty equipment relies on the seamless operation of its individual components. Each part plays a vital role in ensuring smooth performance and longevity. Understanding these components is essential not only for safe operation but also for efficient maintenance and timely repairs. The better one understands the layout and purpose of these elements, the easier it becomes to identify and resolve potential issues.

Main Structural Elements

The foundation of any machine consists of key structural elements that support and stabilize its overall functioning. These components must be sturdy and resistant to wear, ensuring that the equipment can withstand rigorous tasks. Key components include:

- Frame: The core structure that holds all other parts together, offering support and balance.

- Hydraulic System: Powers the movement of various mechanical components, providing force for operations.

- Power Unit: The engine or motor that drives the entire mechanism, delivering the energy required for operation.

Mechanical Components

In addition to the structural elements, mechanical components play a significant role in ensuring the machine functions effectively. These pieces work together to perform specific tasks, from movement to control. Major mechanical elements include:

- Wedge: The tool used to apply force and split material into smaller, manageable pieces.

- Control Levers: Allow the user to direct the movement of key parts, offering precision and flexibility in operation.

- Hydraulic Cylinders: Convert hydraulic fluid pressure into mechanical force, enabling the movement of critical components.

Each of these elements is interconnected and designed to function in harmony. Familiarity with their roles and interactions is critical for keeping the equipment in optimal working condition.

How to Read the Components Layout

Understanding how to interpret a layout of mechanical elements is an essential skill for anyone involved in maintaining or repairing equipment. Such visuals provide a detailed view of each individual piece and its position within the overall structure. By reading the layout correctly, one can easily identify the required components, understand their function, and determine how they interact with others.

Typically, these layouts use clear labeling and numbering systems to distinguish between various components. Each item is often accompanied by a description or part number, allowing users to cross-reference and locate the correct replacement or repair part. Additionally, the orientation of the parts is crucial for understanding how they fit together during assembly or disassembly.

- Start with the Legend: The guide often includes a legend or key, which explains symbols, numbers, and abbreviations used throughout the visual.

- Identify Key Sections: Focus on the major subassemblies of the machine to understand how each segment contributes to the overall operation.

- Follow the Flow: Pay attention to the direction of movement or force in the layout. This helps in understanding the functionality of each part in the larger system.

- Check Part Numbers: Verify part numbers and descriptions to ensure you are referencing the correct components for replacement or troubleshooting.

By familiarizing yourself with this system, you’ll be able to quickly locate issues, perform repairs, and maintain the machine’s efficiency over time.

Common Issues and Replacement Components

Heavy-duty equipment, especially machinery that works under constant stress, often faces a variety of issues over time. Wear and tear, environmental conditions, and prolonged use can lead to malfunctioning of certain elements. Recognizing common problems and knowing which components need replacement is crucial for maintaining optimal performance. Addressing these issues promptly helps avoid more serious damage and costly repairs.

Frequent Problems

Several issues are commonly encountered with such machinery. These problems typically stem from the mechanical stress, lack of proper maintenance, or occasional operational errors. Some of the most frequent issues include:

- Hydraulic Leaks: Often caused by worn-out seals or damaged hoses, leading to a drop in pressure and reduced functionality.

- Faulty Control Mechanisms: Overuse can cause the control levers to become unresponsive or stiff, which can make it difficult to operate the equipment smoothly.

- Worn Components: Regular contact with tough materials can cause key elements, like wedges or blades, to become dull or chipped, impairing their efficiency.

- Engine Performance Issues: Engine-related problems such as irregular power output or overheating are common, especially if regular maintenance has been neglected.

Replacement Components

When issues are identified, replacing faulty components is often the most cost-effective solution. Some commonly replaced elements include:

- Seals and Gaskets: Essential for preventing fluid leaks, these components need replacing regularly to maintain hydraulic pressure.

- Control Handles: These can wear down over time and may need to be replaced for smooth and responsive operation.

- Blades and Wedges: These cutting elements lose their sharpness and effectiveness, requiring periodic replacement to maintain performance.

- Filters and Fluid: Hydraulic fluid and filters should be changed at regular intervals to avoid clogs and ensure the system runs efficiently.

By staying on top of common issues and regularly replacing worn components, users can ensure that their equipment continues to operate at its best, minimizing downtime and extending its lifespan.