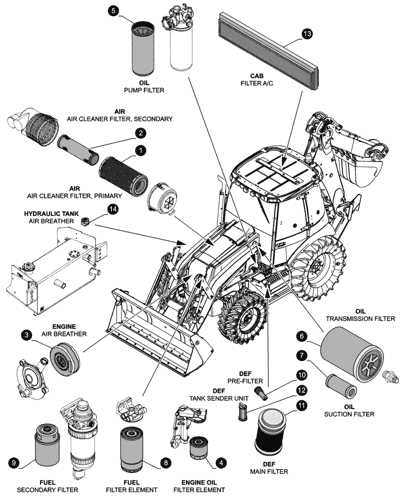

Understanding the inner workings of construction equipment is crucial for efficient maintenance and repair. When it comes to machinery used in digging and lifting tasks, knowing how different systems function together can save time and prevent costly errors. An overview of the various elements that make up such machines helps operators and mechanics ensure smooth operation.

Recognizing the key components involved in the machine’s operation is essential for troubleshooting or replacing parts. These systems, connected through intricate assemblies, perform specific tasks that enable the vehicle to work effectively in demanding environments. Understanding their relationship can make repairs more straightforward and reduce downtime.

One of the most useful tools for this purpose is a comprehensive reference that clearly shows the location and function of each essential part. By using such resources, users can quickly pinpoint issues and ensure that everything is functioning as intended.

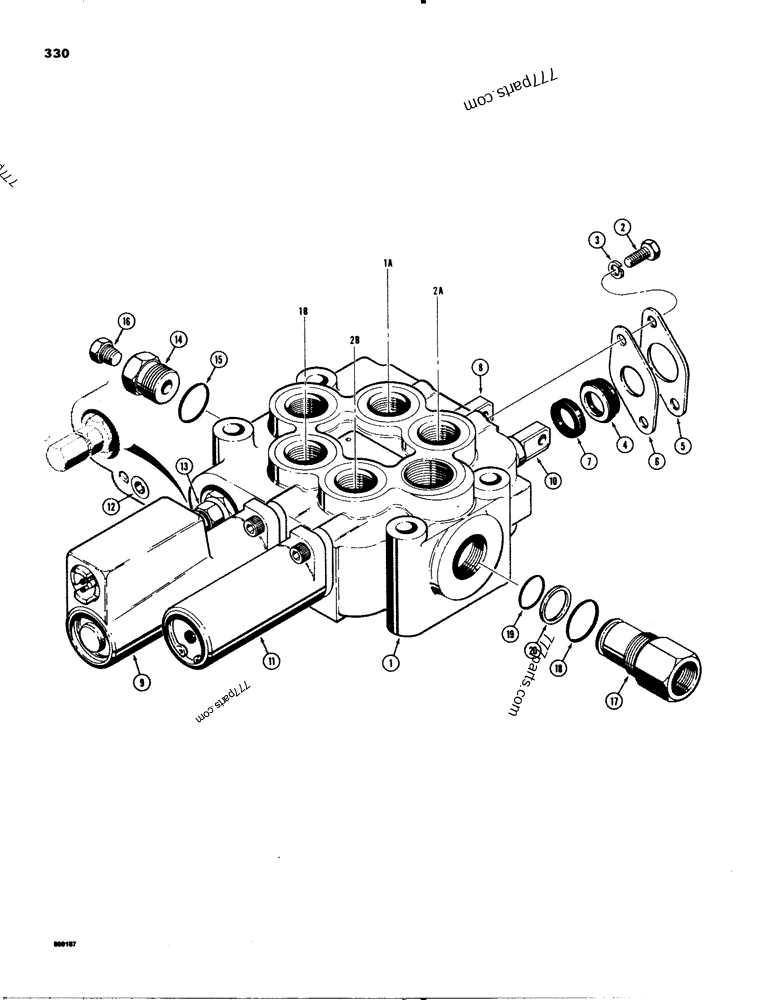

Understanding the Hydraulic System Components

For machinery used in construction and excavation tasks, efficient power transmission is vital to ensure the equipment operates at its full potential. The system responsible for transferring force within the vehicle plays a key role in enabling movement and control. This mechanism relies on a series of interconnected elements that function together to deliver the necessary power to the machine’s operational systems.

Main Elements of the Power Transmission System

At the heart of this system are components such as pumps, valves, and actuators, which work in unison to regulate pressure and direct fluid flow. These elements are designed to handle the heavy demands of construction environments, ensuring that the machine can perform a wide range of tasks, from lifting to digging. Understanding how each component contributes to the overall system allows for more effective maintenance and troubleshooting.

Role of the Control Mechanisms

The control mechanisms govern the direction and speed of fluid flow within the system, allowing operators to precisely manage the machine’s actions. These controls, when functioning optimally, ensure smooth and responsive operation, crucial for tasks that require high levels of accuracy. Regular checks on these controls are necessary to avoid issues that might lead to delays or system malfunctions.

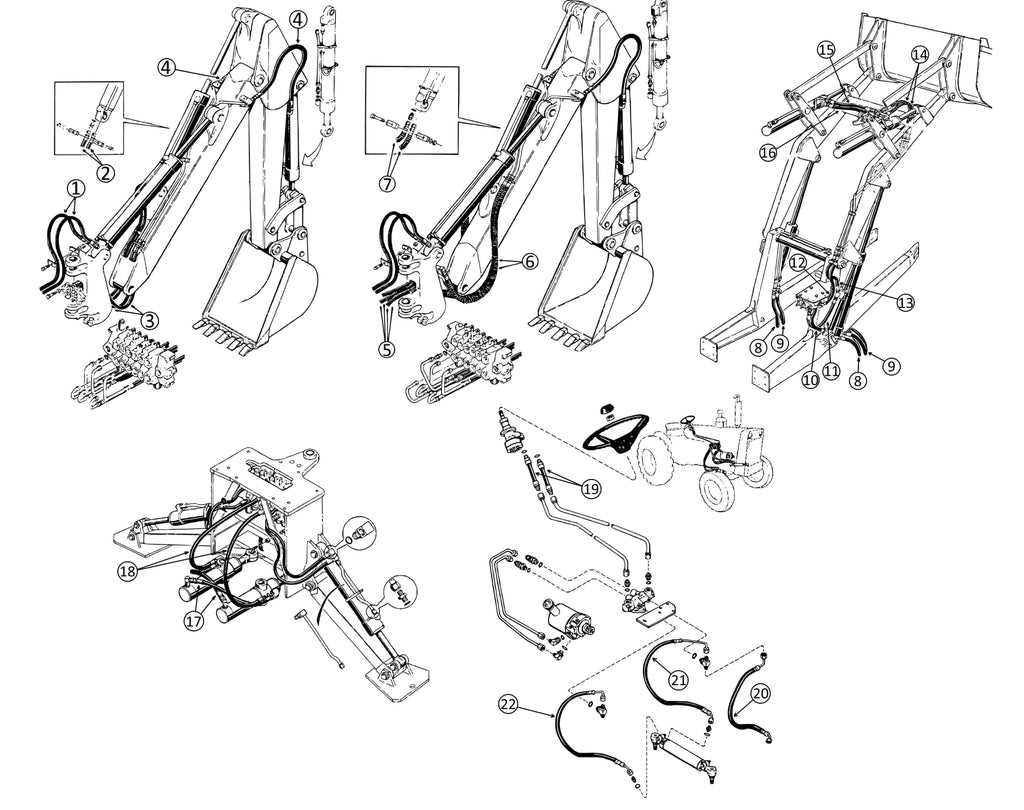

Key Parts of Construction Equipment

The functionality of a construction vehicle relies heavily on its internal components, each serving a specific purpose to ensure smooth operation. Every element plays a critical role in enabling the machine to perform its tasks efficiently. Identifying and understanding these components is essential for proper maintenance, repair, and overall equipment longevity.

Primary Components of the Machine

Various systems and structures within the vehicle contribute to its operational capabilities. The following list highlights some of the essential components:

- Engine: Powers the vehicle and drives all other functions.

- Frame: Supports the structure and houses other essential components.

- Boom: Facilitates movement and lifting of materials.

- Bucket: Used for digging, lifting, and moving materials.

- Transmission: Manages the vehicle’s speed and direction.

Functional Systems Involved

In addition to the main components, the vehicle contains several systems that work together to provide control and power to the machine:

- Power Steering: Allows for smooth turning and directional control.

- Brake System: Ensures safety by controlling speed and stopping the vehicle.

- Electrical System: Powers lights, indicators, and other necessary functions.

- Cooling System: Prevents overheating of the engine and other vital parts.

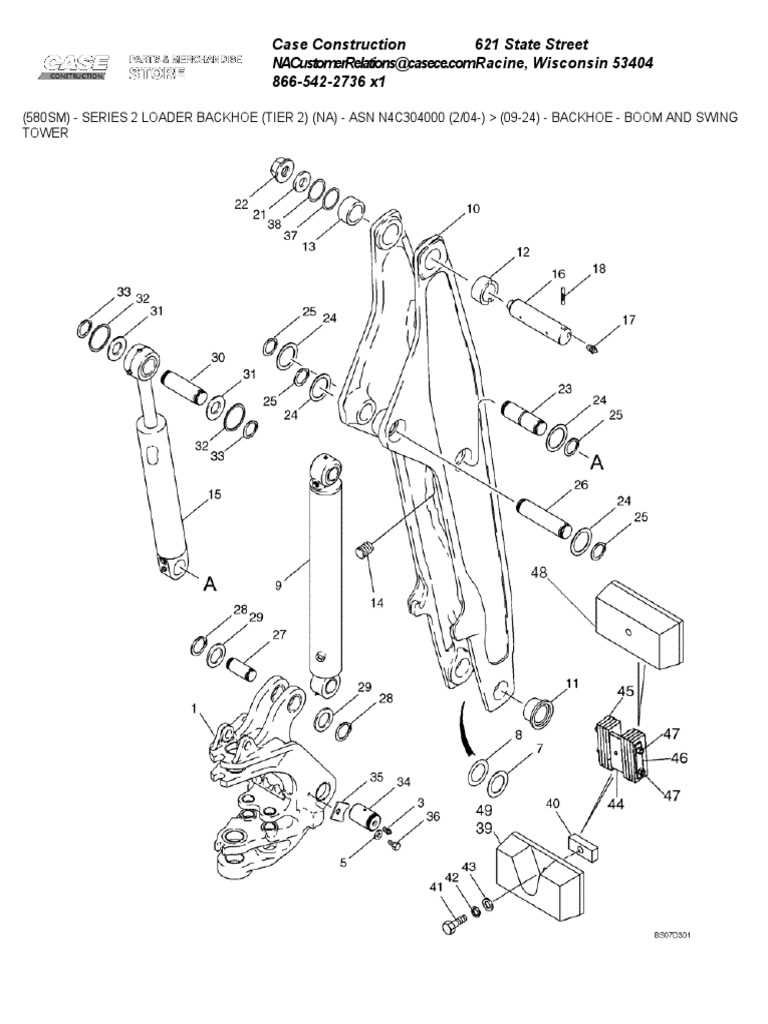

How to Use the Parts Diagram Effectively

Understanding how to navigate and utilize reference guides is key for anyone working with construction equipment. These guides provide valuable information on the internal structure of a machine, allowing users to identify each component and its function. By following the right approach, operators and mechanics can quickly locate specific parts, saving both time and effort during maintenance or repairs.

Start by familiarizing yourself with the layout of the reference guide. Typically, these guides are organized into sections that focus on different systems of the machine. By recognizing the grouping of related components, users can narrow down their search and identify the part they need to work on.

It’s also important to pay attention to the labels and identifiers used in the guide. These will help you match each component with its real-world counterpart. Ensuring that you’re looking at the right system or section makes troubleshooting much easier and more accurate, avoiding unnecessary confusion.