In various mechanical systems, several crucial elements work together to provide smooth and effective operation. These components, each with its distinct role, are essential for the overall functionality of the machinery. A clear understanding of how they interact can help in troubleshooting, maintenance, and performance enhancement.

To grasp the full scope of these mechanisms, it’s important to explore each key segment individually. By breaking down their functions and visualizing how they fit together, one can gain insight into the precise engineering behind the system’s efficiency.

Recognizing the importance of each part allows for a better approach to repairs and improvements. Understanding the structure also paves the way for optimizing performance in the long run, ensuring that every piece fulfills its purpose seamlessly.

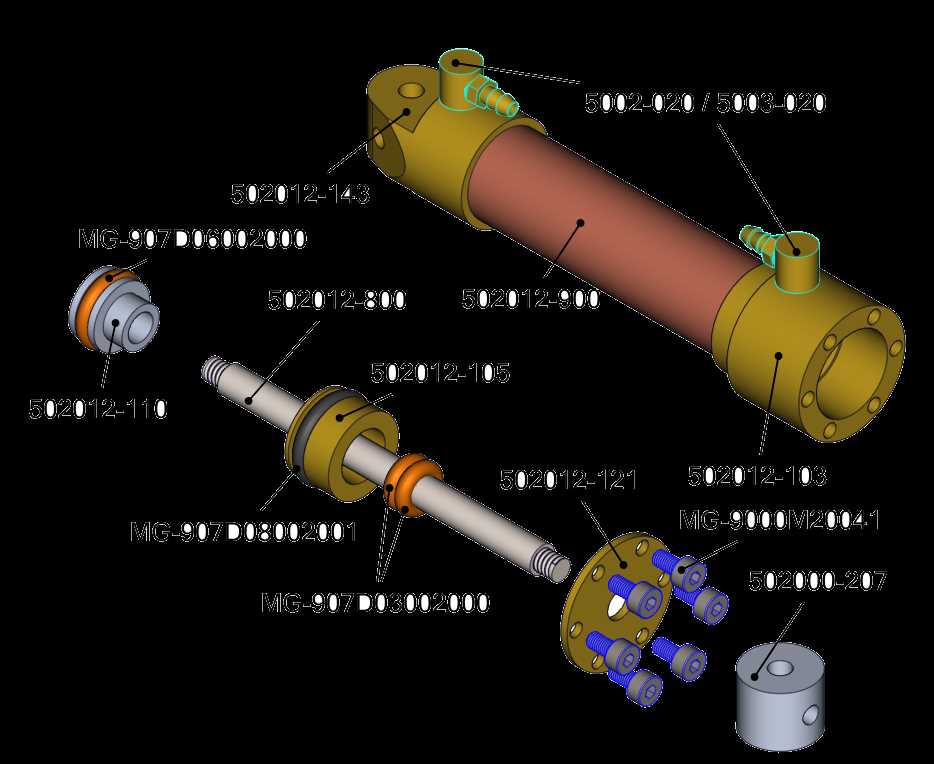

Hydraulic Cylinder Key Components Overview

In every mechanical system, there are essential elements that allow for controlled movement and force. These components must work together efficiently to ensure the system performs optimally under various conditions. A deep understanding of these key elements is critical for anyone involved in maintenance, repair, or performance analysis of these systems.

Main Structural Elements

The primary structural elements of the system are responsible for providing the framework that supports all other components. These include the casing, which houses the internal mechanisms, and the connecting structures that facilitate movement. Each piece must be crafted to withstand high pressures and stress, ensuring that the entire system operates without failure.

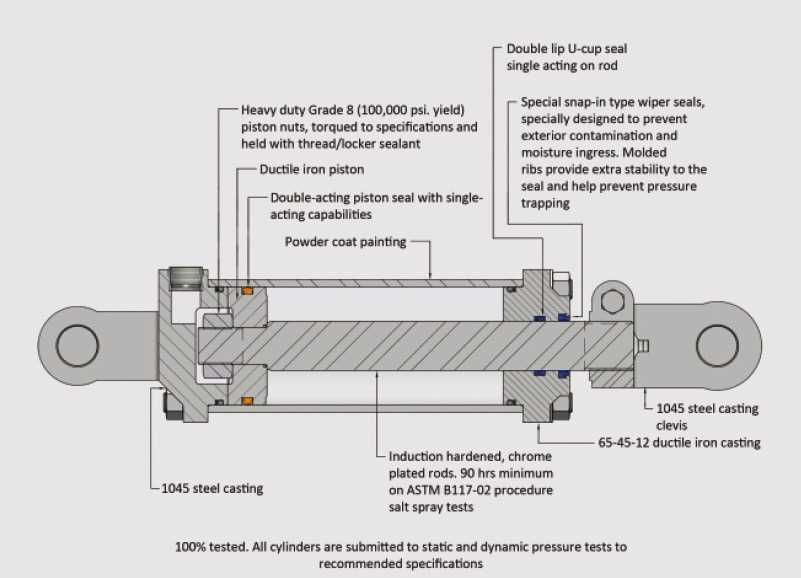

Functional Components and Their Roles

Within the system, several functional components play specific roles in converting energy into motion. These include seals, rods, and pistons, each contributing to the system’s efficiency and longevity. Seals prevent leaks and ensure pressure is maintained, while the rod and piston work in tandem to produce linear motion, making the system capable of precise and powerful movements.

Detailed Diagram of Hydraulic Cylinder Parts

To fully comprehend how a mechanical system functions, it is crucial to understand the intricate layout of its key elements. These components work in harmony, and a clear representation of their arrangement can provide valuable insights into their roles and interactions. Each part plays a distinct function, contributing to the overall performance and efficiency of the system.

By examining the layout of the internal and external elements, it becomes evident how each piece contributes to the movement and energy transfer. The arrangement ensures that all components operate in unison, achieving the desired force and motion with precision. This detailed structure is essential for troubleshooting and maintaining system reliability over time.

Functions of Each Hydraulic Cylinder Part

Each component in a mechanical system serves a specific purpose, contributing to the overall function and efficiency. Understanding the role of every individual part is essential to appreciating how the entire system operates seamlessly. By focusing on each element, it becomes possible to optimize performance and address potential issues more effectively.

Key Functions of Essential Components

Each segment of the system has a specialized function that supports the overall process. Here are the primary roles of the core components:

- Seals: These prevent fluid leaks and maintain internal pressure, ensuring the system remains efficient.

- Pistons: Responsible for transferring force, the pistons create linear motion by moving within the housing.

- Rod: The rod connects to the piston and transmits the generated force, driving the mechanical movement.

Supporting Functions for Optimal Operation

In addition to the main functional components, there are several supporting elements that ensure smooth operation:

- Housing: The outer structure that encases and protects internal elements, allowing for pressure buildup and safe operation.

- Connectors: These allow for the attachment of the system to other mechanical devices, enabling synchronized movement.