Every appliance designed for producing frozen cubes consists of several key elements that work in tandem to deliver the desired outcome. Recognizing how these components interact can help you maintain, troubleshoot, and optimize the device’s efficiency. In this guide, we will take a closer look at the various functions and roles each element plays within the system.

Exploring the key features reveals how different mechanisms are connected to ensure smooth operation. By examining the layout of these components, users can pinpoint issues, identify replacement needs, and understand the machine’s overall design.

Recognizing potential malfunctions is crucial when facing performance challenges. A thorough understanding of how each part contributes to the freezing process can help in early detection of faults, ultimately aiding in repairs and prolonging the lifespan of your appliance.

Key Components of an Ice Maker

In any appliance designed to produce frozen cubes, there are several essential elements that contribute to its efficient operation. Understanding these features allows users to troubleshoot and maintain the unit effectively, ensuring its longevity and reliable performance. Below are the critical components that work together in the process.

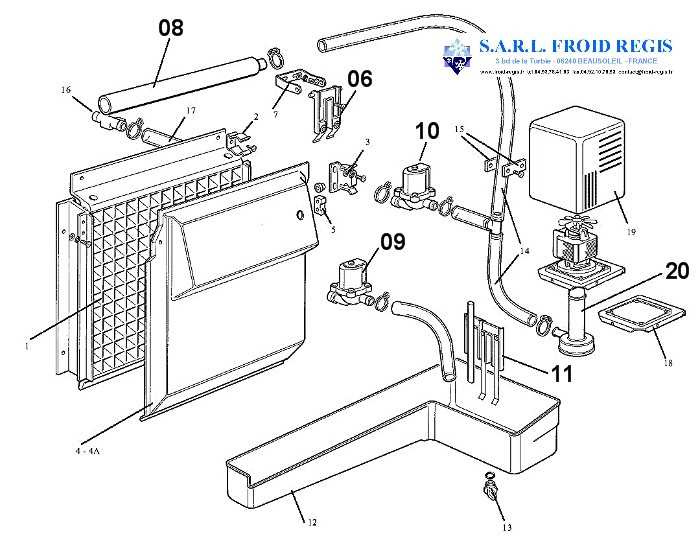

- Water Reservoir – The initial holding tank where water is stored before being frozen into cubes.

- Heating Element – A component responsible for slightly warming the frozen cubes to help release them from the mold.

- Evaporator – The area where cold temperatures are generated, initiating the freezing process.

- Compressor – A crucial part that circulates the refrigerant, maintaining the necessary cold environment within the unit.

- Water Valve – Controls the flow of water from the reservoir to the freezing compartment when needed.

Each of these elements plays a specific role in the freezing cycle, ensuring that the appliance works smoothly and produces consistent results. Understanding their individual functions can greatly help when performing maintenance or diagnosing any potential issues.

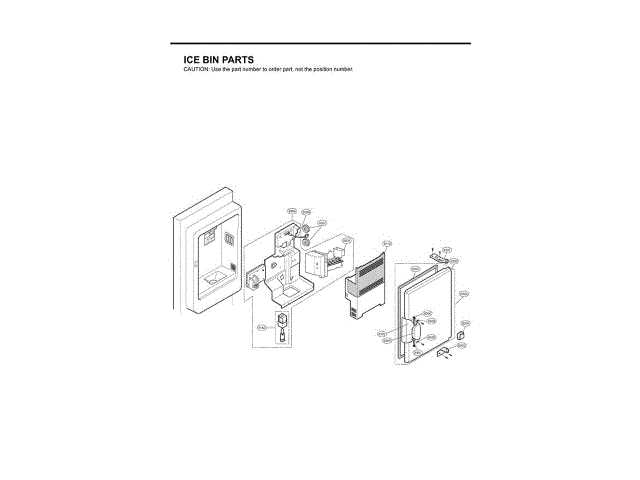

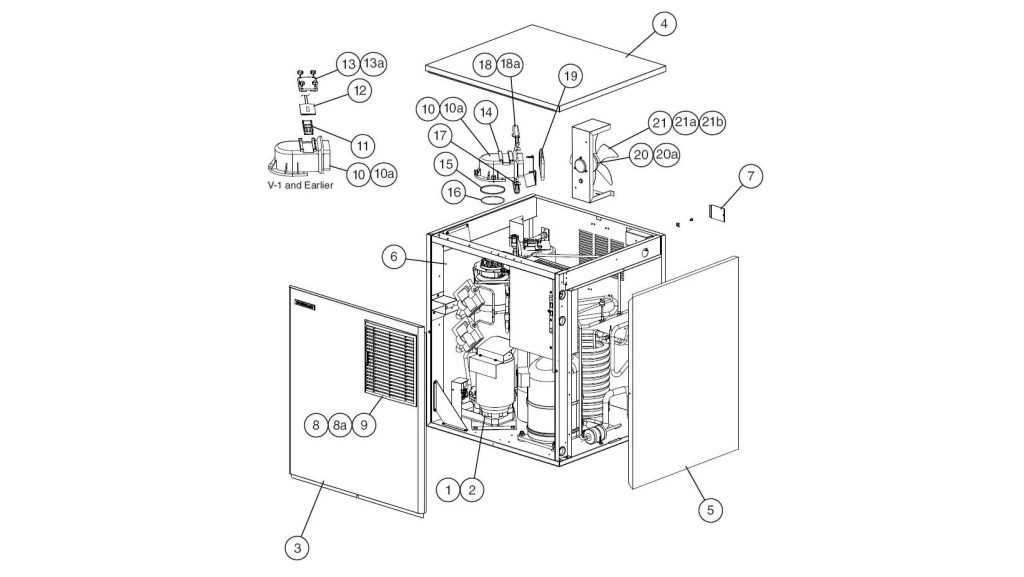

How to Identify Ice Maker Parts

Recognizing the individual components of a freezing appliance is crucial for maintenance, repair, and troubleshooting. Each element has a unique role in the operation, and identifying them allows for more accurate diagnosis and effective interventions when issues arise. Knowing what each feature looks like and how it functions within the system is key to ensuring smooth performance.

Start by locating the most accessible elements, such as the water inlet valve and control panel, which are usually easy to identify by their placement and connections. Once these are recognized, move on to other internal components like the evaporator or compressor, which might require a closer inspection or even disassembly of the unit for a better view.

Using a reference guide or a manual specific to your unit model can significantly help in identifying each element, as components may differ slightly between designs. Paying attention to markings, labels, or visual cues can also guide you in distinguishing the features and understanding their role within the overall system.

Common Ice Maker Repair Issues

Appliances designed for producing frozen cubes are subject to wear and tear, and over time, certain issues can arise that affect their performance. These problems may range from minor inconveniences to more significant malfunctions that require professional intervention. Recognizing these common issues early can help prevent further damage and ensure the unit operates at its best.

Water Flow Problems

A frequent issue is improper water flow, which can result from a clogged valve or a malfunctioning water supply. This can prevent the appliance from filling with enough liquid to produce the desired frozen cubes. Checking the water inlet valve and ensuring that the supply line is clear often resolves this issue.

Freezing Cycle Failures

If the freezing process isn’t occurring as expected, it could be due to issues with the refrigerant or the evaporator. Inadequate cooling may indicate a problem with the compressor or a refrigerant leak, both of which typically require professional repair or replacement to restore functionality.