When it comes to maintaining complex refrigeration equipment, understanding the internal structure and arrangement of its key elements is crucial. Recognizing how each component interacts can significantly improve the efficiency of your maintenance and troubleshooting efforts.

By learning the layout of essential components, users can easily identify individual parts and comprehend their specific functions. This knowledge empowers users to perform repairs, make adjustments, and ensure optimal performance without relying heavily on external support.

Maintenance becomes more manageable when one is familiar with the arrangement and connections between parts. With the right insights, even intricate machinery can be understood and managed with greater confidence.

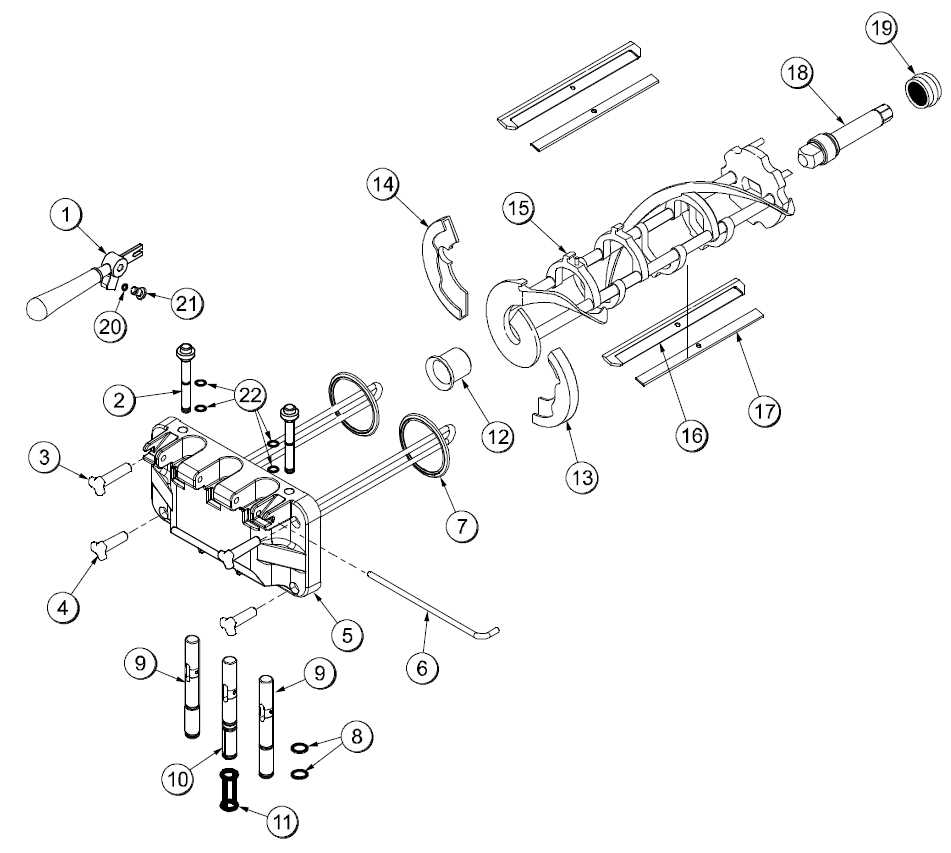

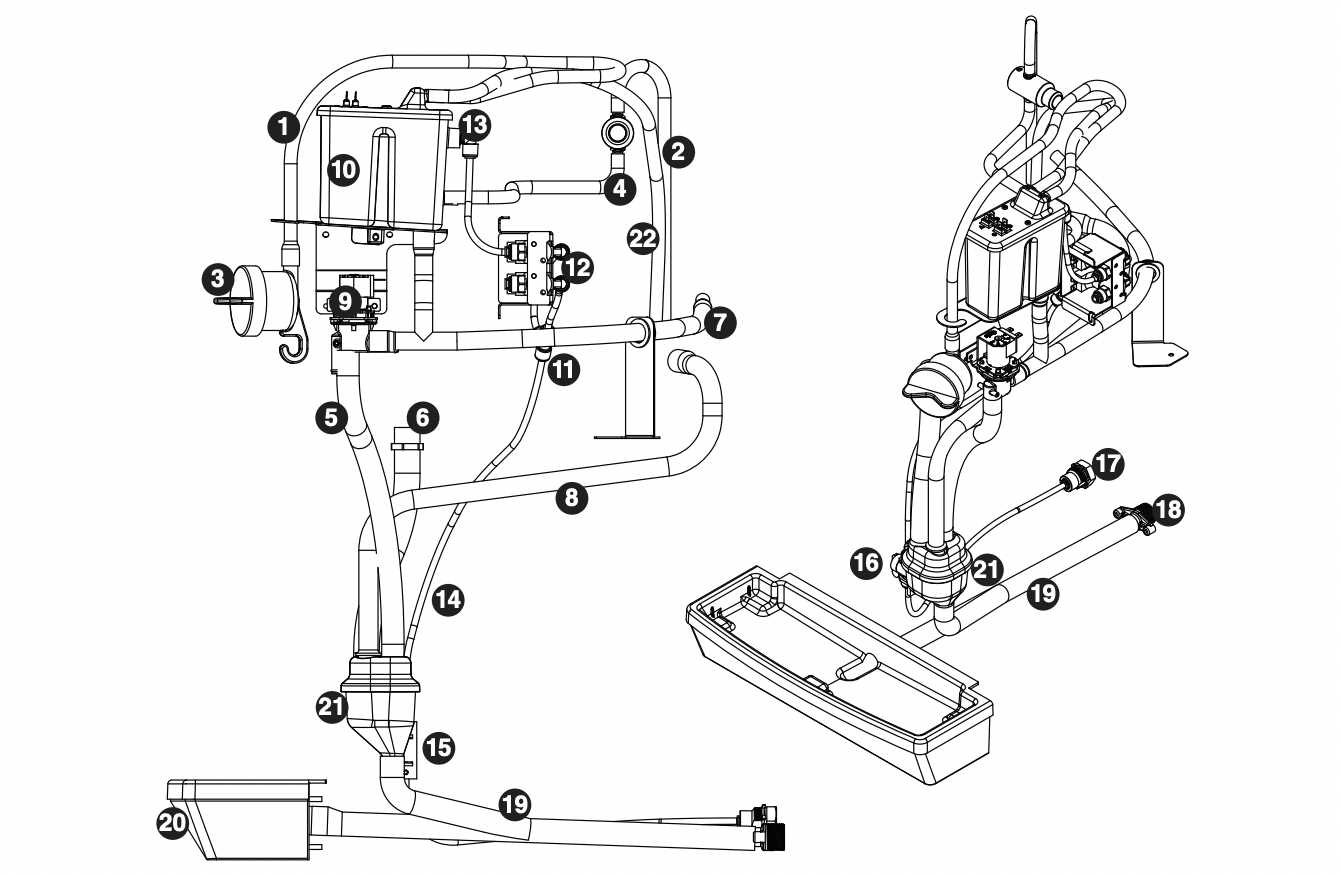

Understanding Component Layout

To ensure smooth operation and effective troubleshooting, it is essential to grasp the arrangement and function of various internal elements within your equipment. A clear understanding of how these components are structured allows for better management, identification, and resolution of issues that may arise during use.

Each element plays a specific role in the overall function of the system, and their interconnections are key to maintaining performance. Recognizing how components fit together provides a foundational knowledge for both routine maintenance and emergency repairs, making it easier to address problems as they occur.

Familiarity with the layout not only enhances the ability to pinpoint potential issues but also ensures that users can perform optimally, reducing downtime and maximizing efficiency. Understanding this system architecture empowers users to take proactive steps in keeping the equipment running at its best.

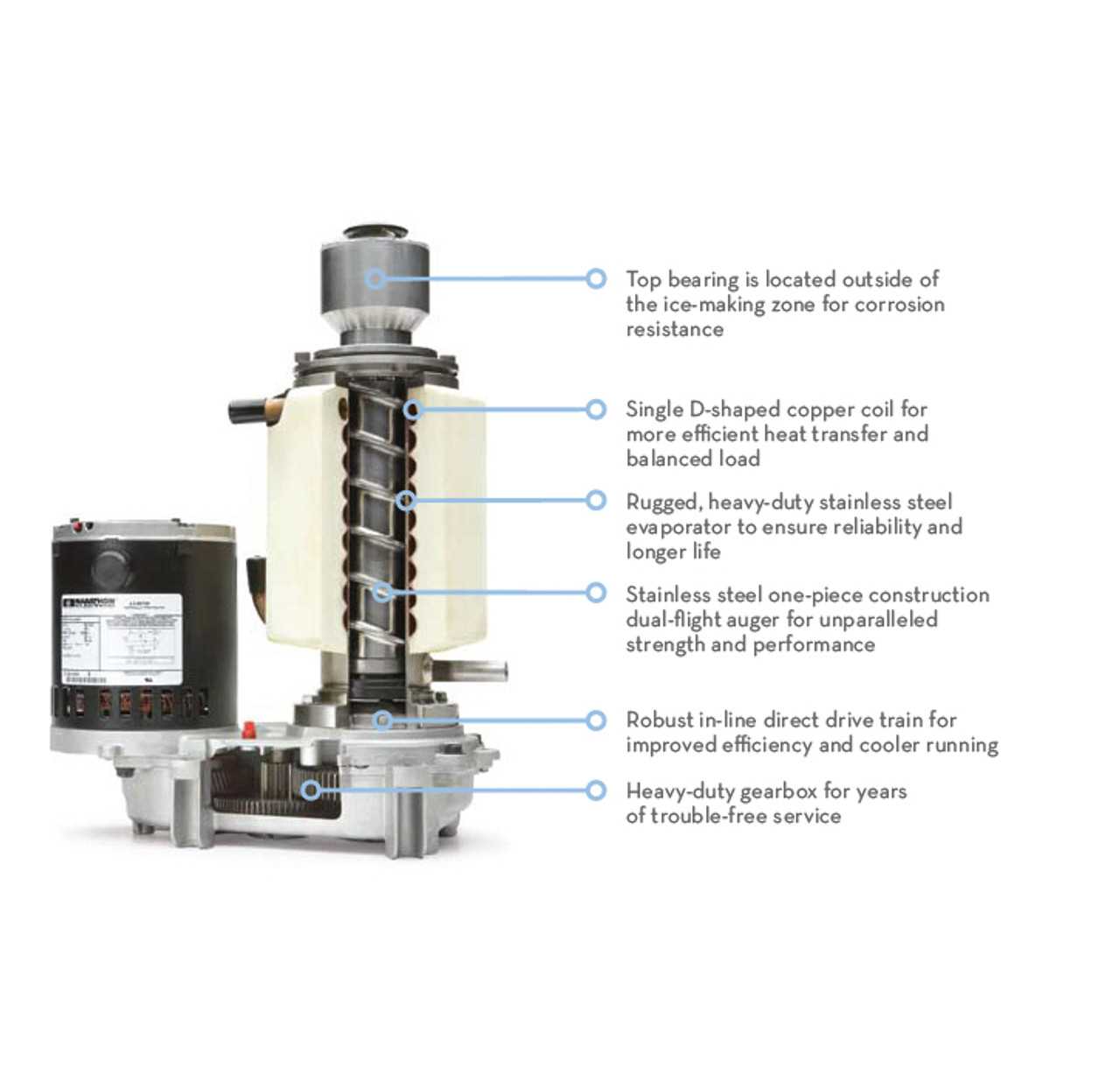

Essential Elements for Efficient Maintenance

Proper upkeep of any complex system requires attention to its core components, which are responsible for its smooth operation. Knowing the most critical elements that require regular inspection and care ensures that the system remains functional and performs at its best. Without this knowledge, maintenance becomes more challenging and less effective.

Key Elements to Inspect Regularly

Among the crucial components are those that directly affect performance and longevity. Regularly checking these parts can prevent costly breakdowns and reduce the need for extensive repairs. Pay special attention to areas such as the water delivery mechanism, cooling units, and filtration systems, as these are often the first to wear out due to constant use.

Importance of Regular Maintenance

By focusing on the essential elements, you can keep the system running smoothly. Timely intervention in these areas can extend the lifespan of the equipment, improve efficiency, and save time and money in the long run. Understanding which components are vital will guide your maintenance practices and ensure that your system operates reliably.

How to Read the Component Layout

Understanding how to interpret the layout of internal system elements is crucial for efficient troubleshooting and maintenance. A clear comprehension of the visual guide allows users to quickly identify each part’s position and connection, helping them locate issues with precision. Mastering this skill is an essential step in ensuring the equipment runs smoothly.

Begin by familiarizing yourself with the overall structure and symbols used in the guide. Recognizing the common representations for each component will enable faster navigation and better understanding of their interrelations. This knowledge empowers users to make informed decisions during both routine maintenance and urgent repairs.

Focus on key areas such as flow paths and connections between major components. These sections often indicate how each part interacts with others and help in diagnosing problems that might not be immediately obvious. Being able to read this visual map effectively ensures a more efficient repair process and minimizes downtime.