Proper knowledge of the internal components of refrigeration units is essential for efficient maintenance and repair. Whether you’re a technician or a user, understanding the layout of crucial machine elements can save both time and money. By familiarizing yourself with the system, you can easily pinpoint issues, identify worn-out pieces, and make informed decisions about replacement or service needs.

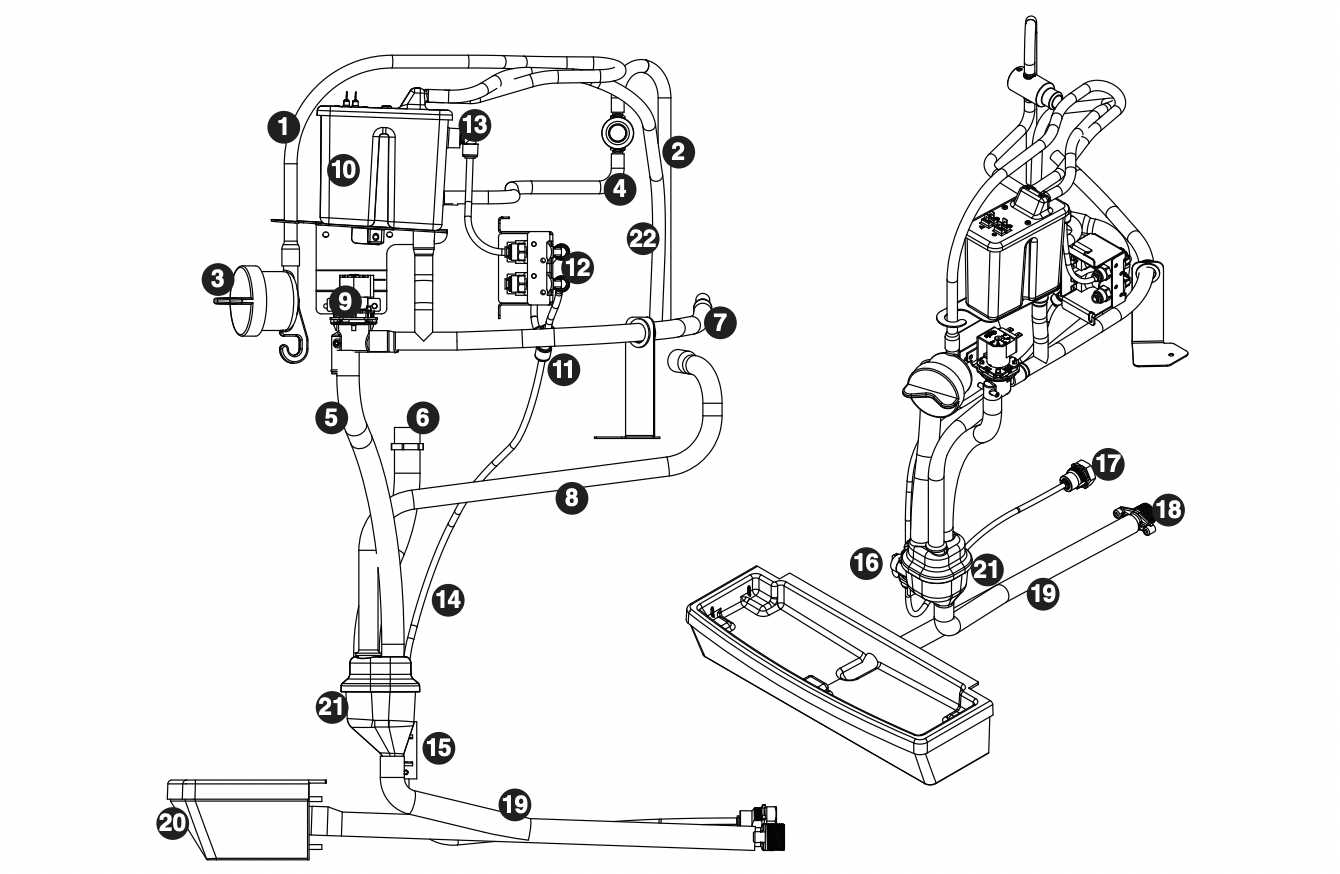

Each cooling system consists of various key elements, each playing a specific role in the production and preservation of ice. Knowing their locations and functions allows for smoother troubleshooting and ensures long-term performance. A visual representation of these components can help you see how they work together to form a reliable and efficient unit.

Maintenance becomes much simpler when you can quickly identify the individual elements within the setup. With the right resources, you can address minor issues before they escalate into expensive repairs, ultimately extending the lifespan of your equipment.

Understanding Ice O Matic Parts Layout

Efficient operation of refrigeration machines relies on understanding the positioning and function of their individual components. Each piece has a specific role, contributing to the overall performance of the unit. By recognizing these elements and how they interact, users and technicians can troubleshoot more effectively, ensuring smoother operation and quicker repairs when needed.

Each system is organized in a logical layout, where each component is connected to support a specific task. The arrangement helps to simplify maintenance, allowing you to easily spot malfunctions or inefficiencies. Here are some of the main elements that make up the structure:

- Compressor: The heart of the system, responsible for circulating refrigerant through the unit to maintain low temperatures.

- Evaporator: Responsible for cooling and removing heat from the system, allowing ice to form efficiently.

- Condenser: Works to release heat from the refrigerant, ensuring the system doesn?t overheat and loses efficiency.

- Expansion Valve: Controls the flow of refrigerant into the evaporator, regulating the freezing process.

- Water Valve: Ensures the proper water flow for freezing and maintaining the ice-making process.

Understanding the location and function of these components will help in identifying potential issues during routine maintenance. Whether you’re replacing a worn-out element or simply inspecting the system, a clear understanding of how the layout contributes to the operation will guide your decisions. This layout also ensures the smooth flow of energy and refrigerant throughout the system, allowing for uninterrupted ice production.

Key Components of Ice O Matic Machines

Understanding the essential components of refrigeration equipment is crucial for maintaining optimal performance. Each element within the system is designed to work in harmony, ensuring the unit operates smoothly and efficiently. Recognizing these critical parts allows users and technicians to troubleshoot and repair any issues quickly, minimizing downtime and extending the machine’s lifespan.

Among the most important components are the following:

- Compressor: Responsible for circulating refrigerant, the compressor maintains the flow necessary for cooling and ice production.

- Evaporator: This component absorbs heat from the surroundings and cools down the system, aiding in the ice-forming process.

- Condenser: It releases excess heat from the refrigerant, helping the system maintain balance and preventing overheating.

- Water Pump: Ensures the consistent flow of water to the freezing unit, which is essential for creating quality ice.

- Expansion Valve: Regulates the flow of refrigerant into the evaporator, controlling temperature and pressure to optimize the freezing cycle.

- Control Board: The brain of the unit, which monitors and controls the various operations of the system to ensure proper function.

These key elements work together to deliver reliable performance. Proper maintenance and understanding of their roles can prevent costly repairs and improve the efficiency of the machine over time.

How to Read the Ice O Matic Diagram

Understanding the layout of a refrigeration system is essential for effective maintenance and troubleshooting. A visual guide can help technicians quickly identify components, understand their interactions, and pinpoint areas that may need attention. By mastering how to read these illustrations, you?ll be able to make informed decisions about repairs, replacements, and adjustments.

Familiarizing with the Symbols

The first step in interpreting these illustrations is recognizing the common symbols used for each component. Each part of the system, such as the compressor, condenser, or expansion valve, is represented by a specific symbol. These visual representations help you quickly understand what each part does without needing to read through extensive manuals. For example, a circle may represent a pump, while a square could denote a valve or sensor.

Understanding the Connections

Once you?re familiar with the symbols, it?s important to focus on the connections between the components. Lines often indicate the flow of refrigerant, water, or energy throughout the system. Arrows and labels will show the direction of flow, helping you understand the sequence of operations within the unit. This information is crucial when diagnosing any potential faults in the system, as it allows you to trace the path from one element to another.

Take time to review these diagrams as they offer a detailed map of your machine?s inner workings. Knowing how to interpret these illustrations will empower you to carry out repairs and ensure that your equipment runs efficiently.

Step-by-Step Guide for Identifying Parts

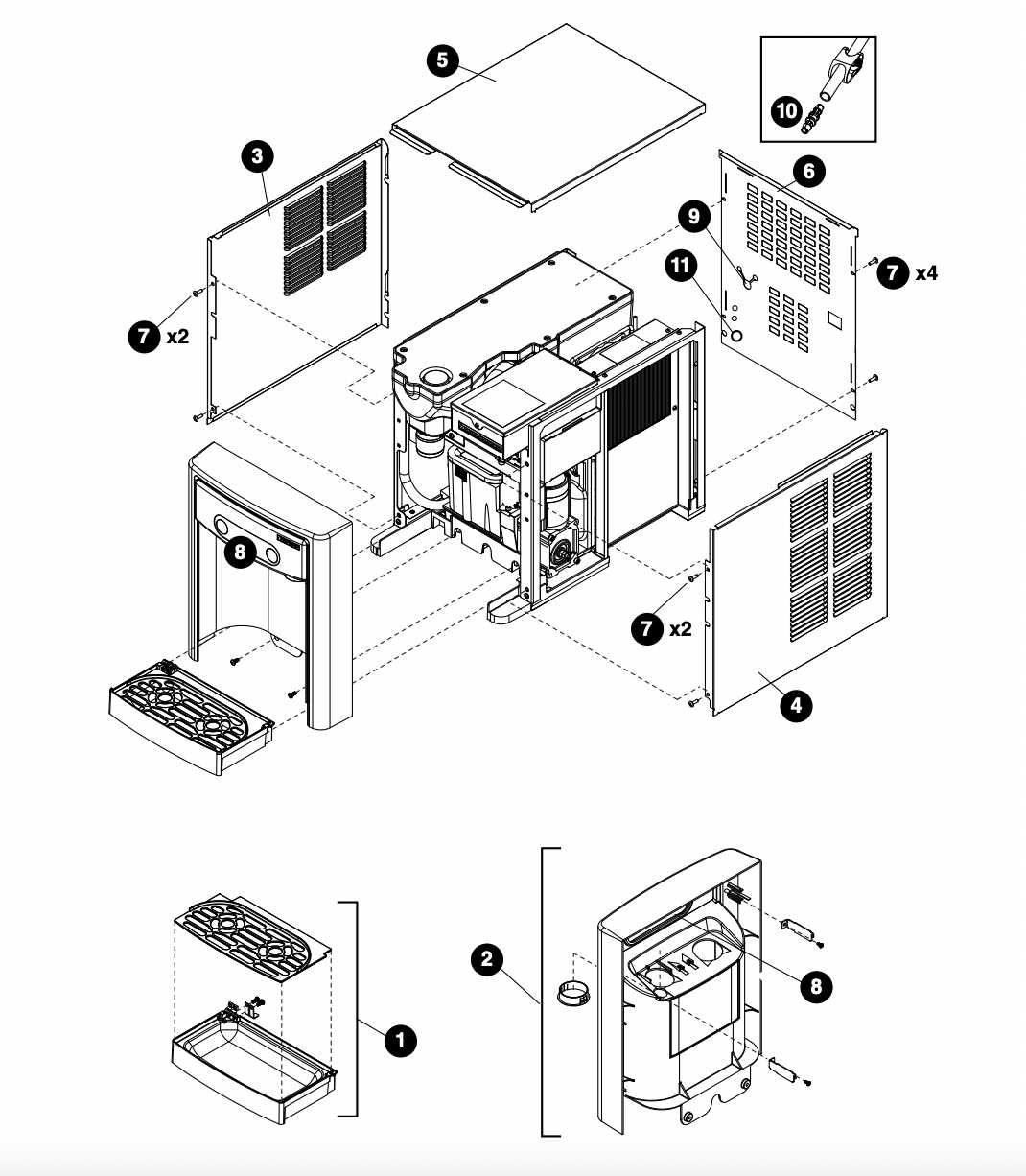

Accurately identifying the components within a refrigeration unit is key to ensuring proper function and maintenance. Each element plays a crucial role, and understanding their location and purpose allows you to troubleshoot issues efficiently. This guide will walk you through a clear process to recognize and evaluate each piece, helping you maintain smooth operation.

Step 1: Locate the Key Elements

The first step in identifying components is to know where to find the main sections of the unit. Start by locating the major parts like the compressor, condenser, and evaporator. These components are typically positioned in easily accessible areas, either near the front or sides of the machine. Understanding where these primary elements are located helps narrow down the search for more specific parts.

Step 2: Understand the Function of Each Element

Once you?ve found the major components, focus on understanding their specific functions within the system. For example, the compressor is responsible for circulating refrigerant, while the condenser helps release heat. By learning the role of each element, you can more easily spot malfunctioning components when they arise. Look for markings or labels on the components to help you confirm their identity.

Always refer to the manual or any available guides for more precise details on each part?s placement and function. This will help you avoid confusion and ensure you’re working with the right elements during troubleshooting or repairs.

Familiarizing yourself with these steps will streamline the identification process, making it easier to address any issues promptly and keep the system in optimal condition.

Maintenance Tips Using Parts Diagram

Regular maintenance is crucial for ensuring the longevity and efficiency of refrigeration units. A visual guide can be an invaluable tool in identifying potential issues and performing necessary repairs. By understanding the layout of the system, you can perform preventive measures that address problems before they escalate, keeping the unit running smoothly.

Routine Inspection and Cleaning

One of the most important steps in maintaining equipment is routine inspection. Use the guide to check each component regularly for wear and tear. Pay special attention to parts like the compressor and condenser, which can accumulate dirt and debris. Cleaning these areas improves efficiency and prevents overheating, ultimately extending the life of the machine.

Identifying Issues Early

Visual guides help you detect issues early by clearly illustrating how components interact. For example, if you notice a disruption in the refrigerant flow or an irregularity in water circulation, refer to the guide to pinpoint the exact location of the malfunction. Identifying problems early allows you to act quickly, preventing costly repairs and keeping downtime to a minimum.

Regular maintenance checks using these diagrams will not only keep the equipment in top shape but also reduce the risk of unexpected breakdowns. By staying proactive, you ensure long-term reliability and efficiency.

Utilizing these tools will simplify the maintenance process, making it easier to keep everything running at its best with minimal effort.