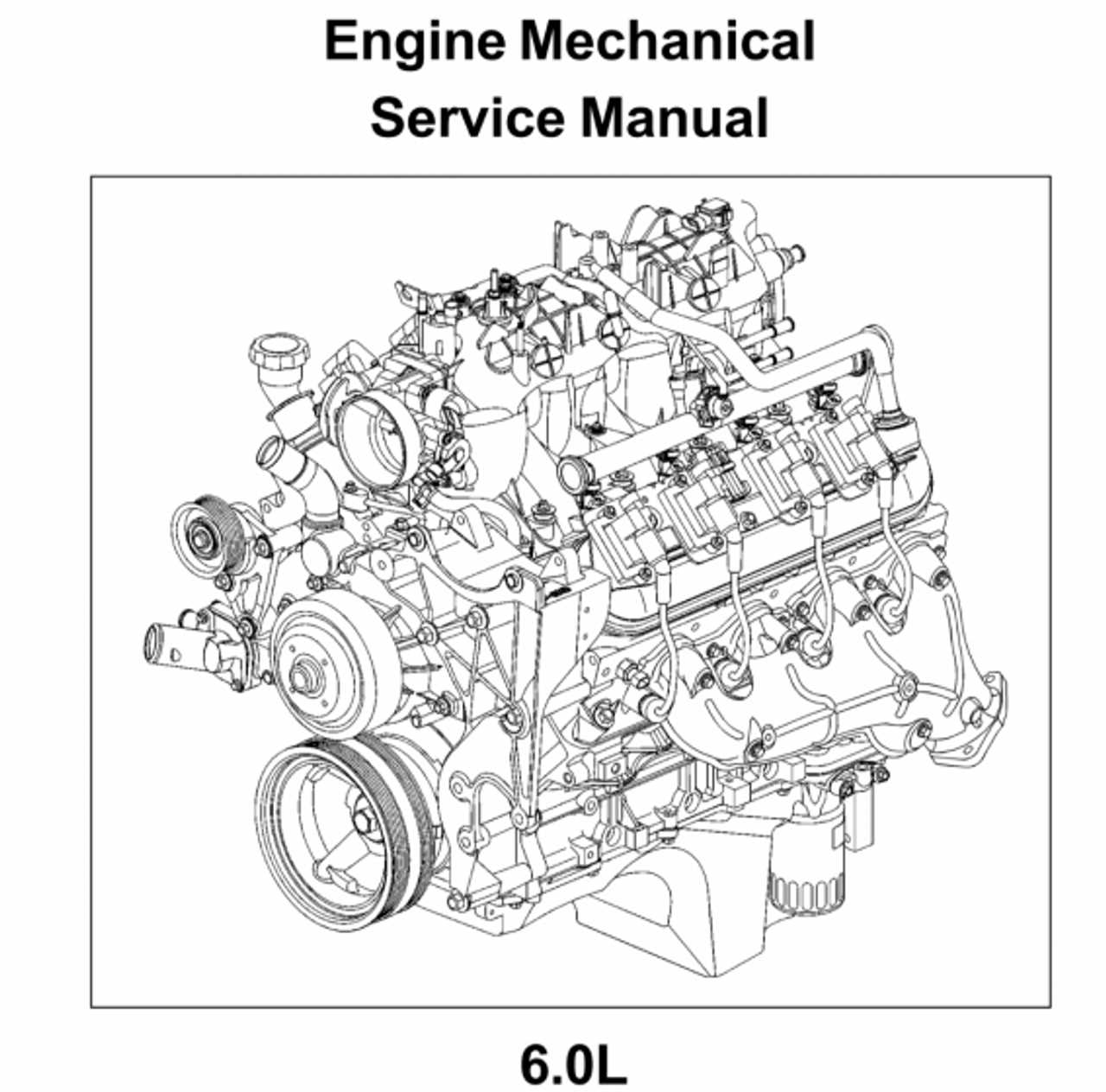

Maintaining and repairing marine engines requires a clear understanding of how various components fit together. Properly identifying each part and its function is crucial for both performance and longevity. Whether you’re performing routine maintenance or addressing specific issues, knowing the structure of the engine can save time and effort.

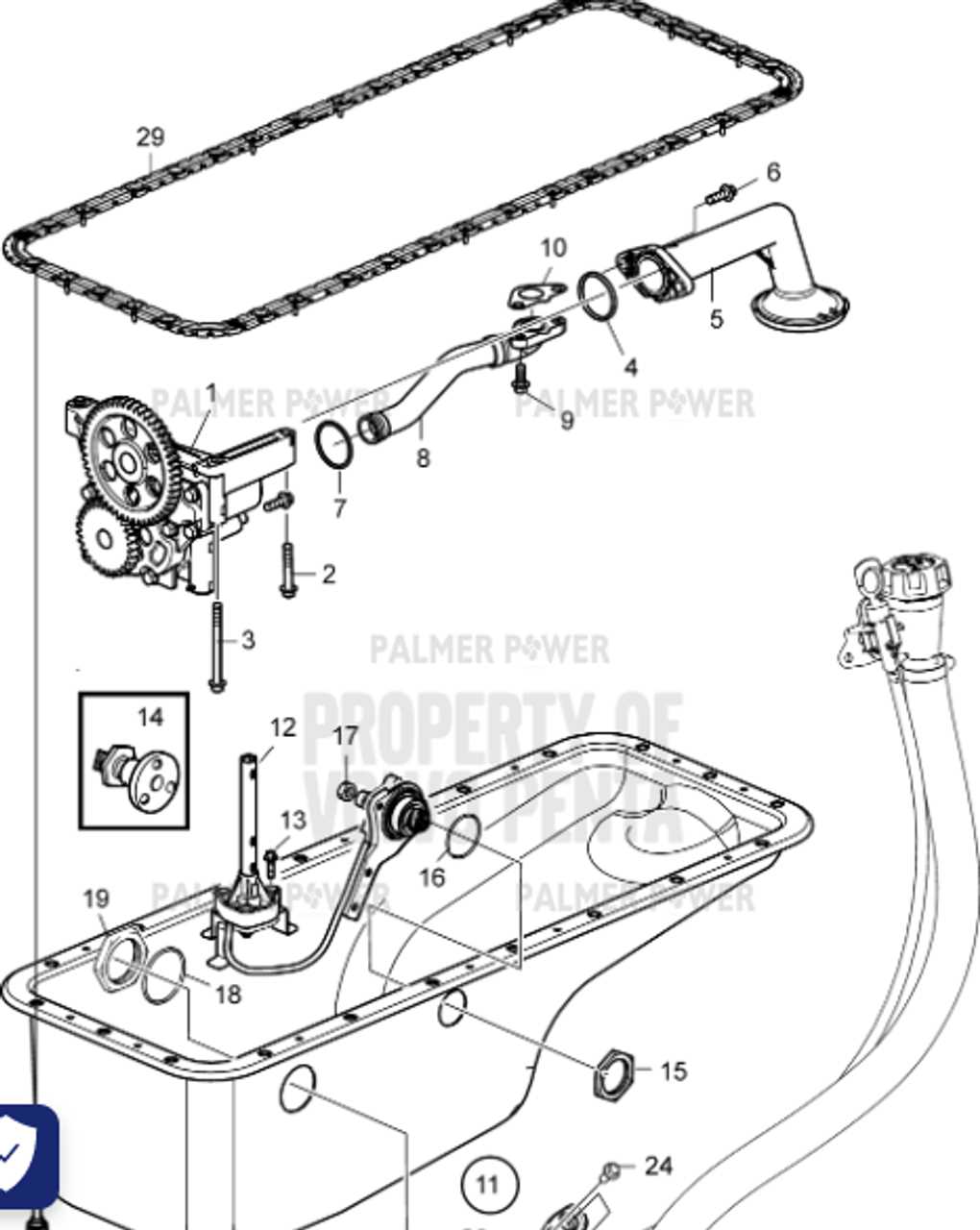

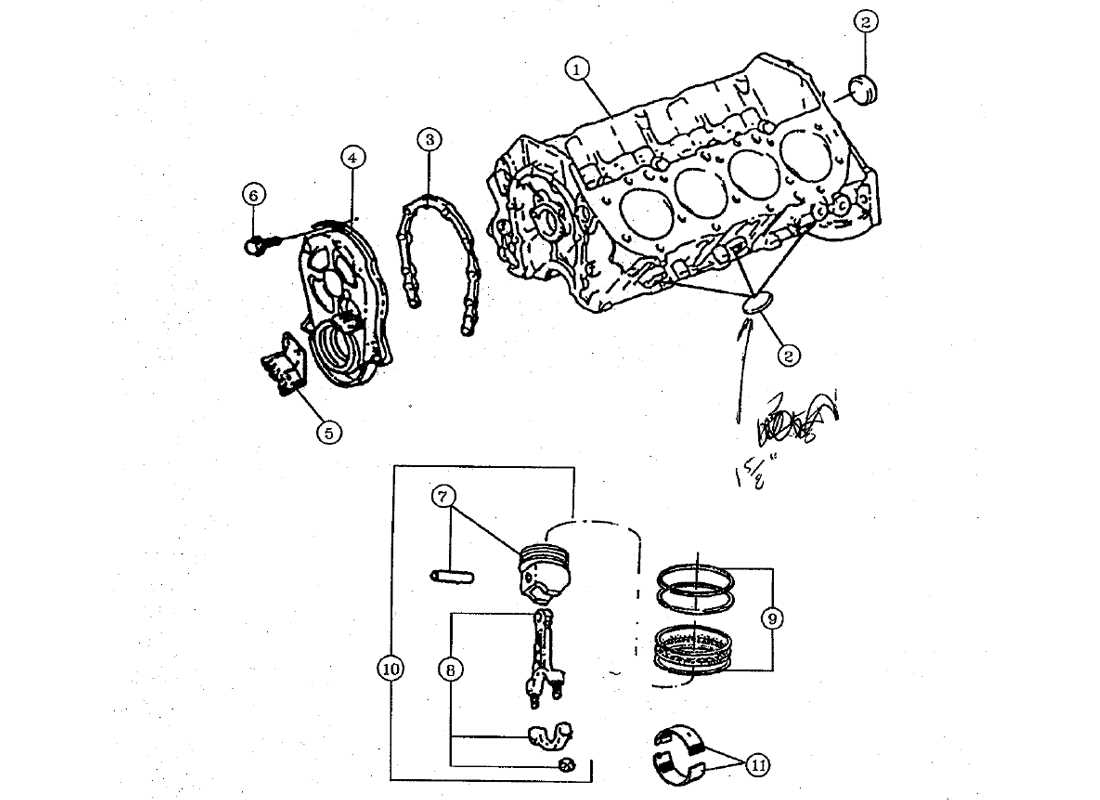

Visual aids such as detailed diagrams can significantly enhance this process by providing a clear representation of the engine’s internal parts. These visuals allow users to easily pinpoint specific components, simplifying the identification of potential problems and the replacement of worn-out pieces.

Having a thorough understanding of the engine’s design ensures that technicians and enthusiasts alike can troubleshoot more effectively, ensuring optimal operation and reducing the risk of unexpected failures during use.

Understanding Engine Components

In any marine engine, each individual component plays a crucial role in ensuring the overall system functions properly. These parts are carefully designed to work together, with each fulfilling a specific purpose, whether it’s generating power, maintaining stability, or managing fuel efficiency. Understanding how these components interact allows for better maintenance and problem-solving.

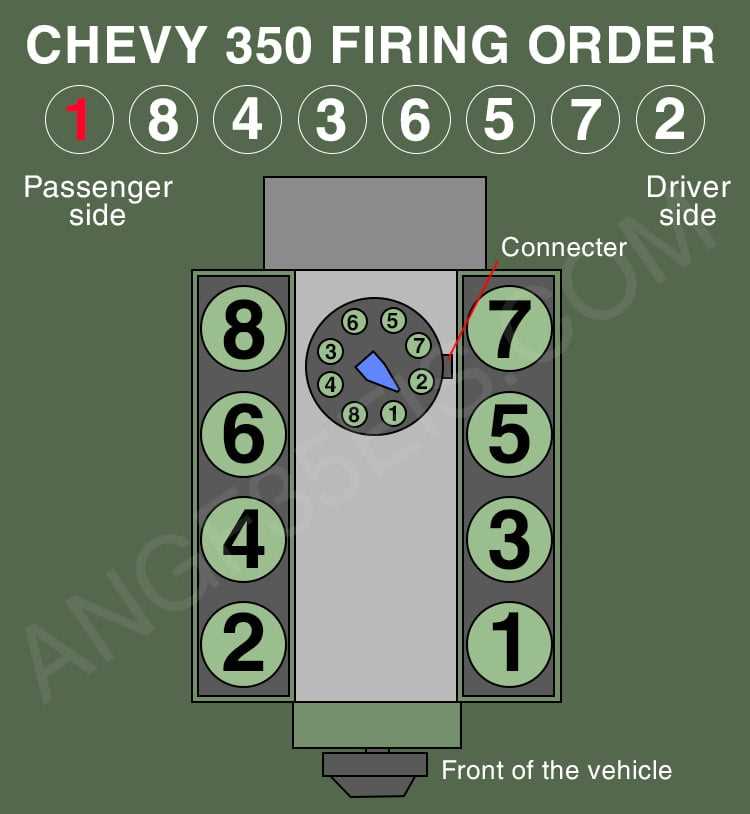

The engine’s structure can be broken down into various systems, each responsible for different aspects of engine performance. From the ignition system to the cooling mechanisms, every part contributes to the engine’s operation. Recognizing the function of each element is key when diagnosing issues or performing repairs.

Additionally, knowing the key components of the engine allows users to detect wear and tear, preventing more significant problems down the line. Regular inspection and understanding the roles of these parts ensure that the engine continues to run smoothly, enhancing both its efficiency and lifespan.

How to Interpret the Component Layout

Understanding the layout of engine components is essential for effective maintenance and repair. These visual representations offer a detailed view of the engine’s structure, allowing users to easily identify each part and its location. By becoming familiar with these layouts, you can troubleshoot issues more efficiently and ensure the correct replacement of damaged components.

Understanding Labels and Symbols

Each part in the layout is typically accompanied by labels or symbols that provide additional information about its function and specifications. Learning to recognize these symbols helps users quickly identify the components that require attention, facilitating a smoother repair or maintenance process.

Step-by-Step Interpretation

To properly interpret the layout, start by familiarizing yourself with the overall structure. Break down the diagram into sections, focusing on one area at a time. Pay attention to connections between parts, as understanding how they interact is critical when diagnosing problems or performing replacements.

Common Issues and Replacements for Marine Engines

Every engine, regardless of its design, faces certain common issues over time. Recognizing these problems early allows for quicker fixes and prevents long-term damage. Many issues stem from wear and tear, improper maintenance, or exposure to harsh conditions. Identifying the symptoms and addressing them promptly is essential to ensure the engine runs smoothly.

Frequent Engine Problems

Several problems are often observed in marine engines, including:

- Overheating due to cooling system failure

- Fuel inefficiency caused by clogged fuel lines

- Ignition issues from damaged spark plugs or coils

- Vibration from loose or worn-out mounts

- Excessive exhaust smoke indicating internal damage

Necessary Replacements

When certain parts show signs of wear or damage, it’s important to replace them to restore optimal performance. Common replacements include:

- Coolant hoses and thermostats to prevent overheating

- Fuel filters and lines to ensure proper fuel flow

- Ignition coils and spark plugs for reliable starts

- Mounts and engine supports to reduce vibrations

- Exhaust components to avoid harmful emissions

Addressing these issues promptly can improve engine performance and extend its life, ensuring a smooth and efficient operation for years to come.