Efficient air systems are essential in various industrial and commercial applications. Knowing the internal structure and functionality of these systems helps in their optimal operation and maintenance. This guide aims to break down the key elements that contribute to the functioning of these systems, providing insights into their role and importance.

Key Elements in an Air System

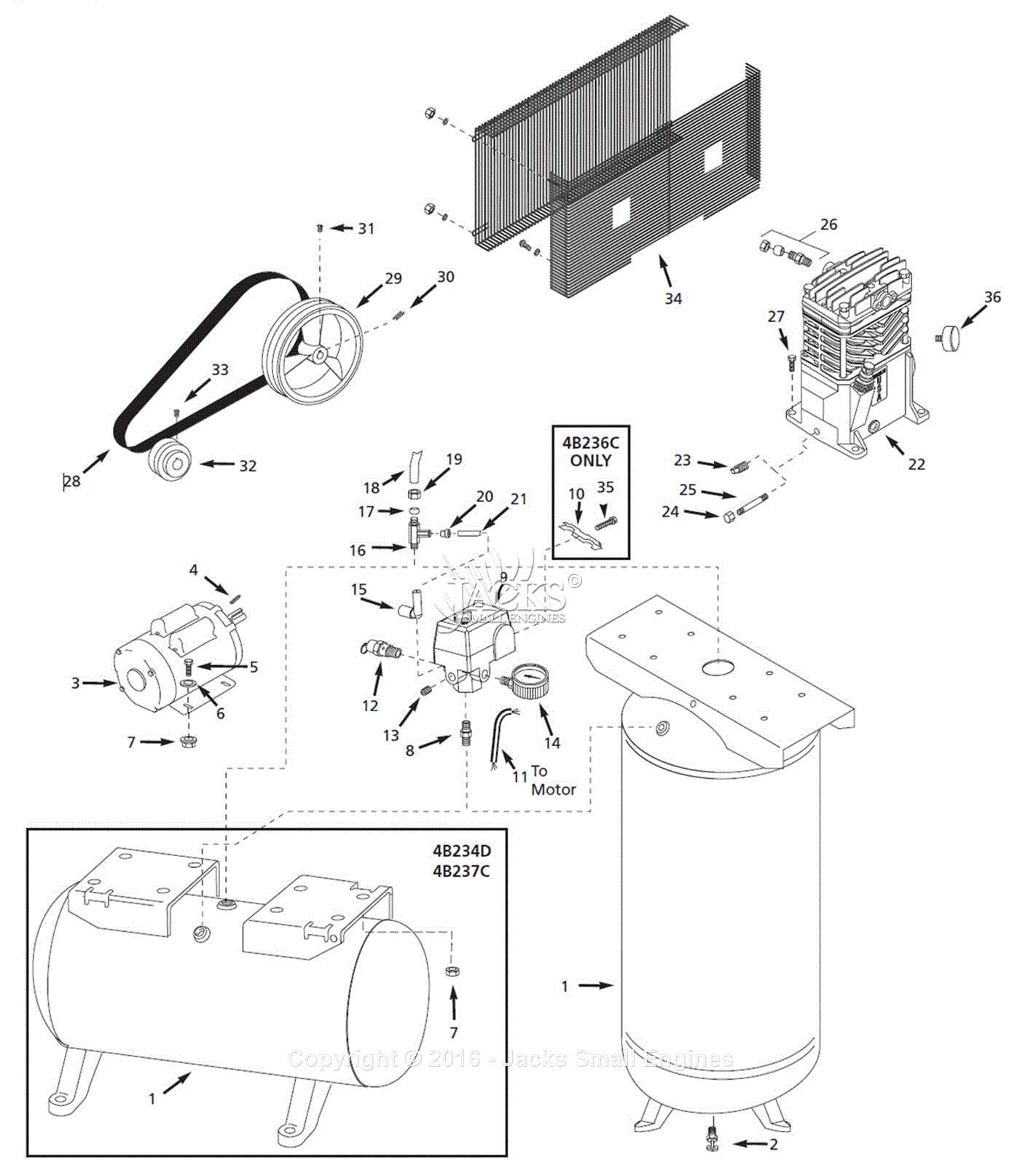

Air systems are made up of various components that work together to generate, control, and distribute air. These parts range from intake valves to specialized pressure regulators, each serving a specific purpose to ensure smooth operation. Identifying and understanding each component is crucial for diagnosing issues and performing effective repairs.

Essential Components

- Intake Valve: Controls the entry of air into the system.

- Pressure Regulator: Maintains the correct pressure levels for proper system functionality.

- Filter: Removes impurities and particles to maintain clean airflow.

- Receiver Tank: Stores compressed air for later use in the system.

Interpreting System Layouts

Understanding the layout of these components is essential when performing maintenance or troubleshooting. By referring to a clear and detailed layout, one can quickly locate and assess each component’s function, helping to identify any malfunctions. These layouts also highlight how each part is interconnected, ensuring that all components work together efficiently.

Steps for Effective Analysis

- Study the general flow of air within the system.

- Locate each component and familiarize yourself with its function.

- Check for any possible points of failure based on the flow and component roles.

Maintaining Optimal Performance

Routine maintenance is key to ensuring that air systems continue to operate efficiently. Regular checks on the individual components can prevent system downtime and prolong its lifespan. Identifying and addressing potential issues early can save time and resources in the long run.

Why Maintenance Matters

Proper upkeep of these systems reduces the likelihood of unexpected failures, ensuring that each part functions smoothly. Whether it’s replacing worn-out filters or adjusting pressure levels, maintaining the system ensures it performs at its best.

Understanding Air System Elements

In any mechanical setup that utilizes air pressure, there are crucial components working together to ensure smooth and efficient operation. Understanding these elements, their functions, and how they interact is essential for anyone involved in maintaining or repairing these systems. This section outlines the primary parts and offers insights into how to read and interpret their layout for better understanding.

Key Components in an Air Pressure System

Air systems consist of various essential parts, each serving a unique purpose to facilitate the flow, storage, and regulation of air. These components range from intake valves to pressure regulators, filters, and storage tanks. Understanding each part’s role is important for effective system management and repair. The proper functioning of these elements ensures that air flows smoothly, maintaining the required pressure and avoiding system malfunctions.

How to Interpret System Layouts

Interpreting the layout of an air pressure system is vital for troubleshooting and maintenance. The diagram usually represents the system’s flow and shows how each component is connected. By understanding this flow, it becomes easier to identify any weak points or areas that need adjustment. It’s important to focus on the way components are arranged and how the air moves through the system to ensure optimal performance.

Step by Step Guide to Reading

To properly read and interpret a system layout, follow these steps:

- Study the flow: Identify how the air moves through the system, starting from the intake to the storage areas.

- Understand each component: Familiarize yourself with the function of each part and how it contributes to the overall process.

- Check connections: Ensure that all parts are properly linked and that there is no obstruction or issue with airflow.

Importance of Maintenance and Component Care

Regular maintenance is essential to keep the air system functioning at its best. Without periodic checks, components can wear out or fail, leading to inefficiency or costly repairs. Simple tasks like cleaning filters, replacing worn-out seals, and ensuring proper lubrication can extend the life of the system and improve its performance. Proactive care minimizes downtime and ensures the system operates smoothly over time.