When maintaining heavy-duty trucks, it is crucial to understand the layout and structure of their essential parts. A clear understanding of each component’s location and function allows for more efficient troubleshooting, repairs, and upgrades. This knowledge enables mechanics and drivers to ensure their vehicle remains in optimal condition over time.

Key Elements of a Truck’s Construction

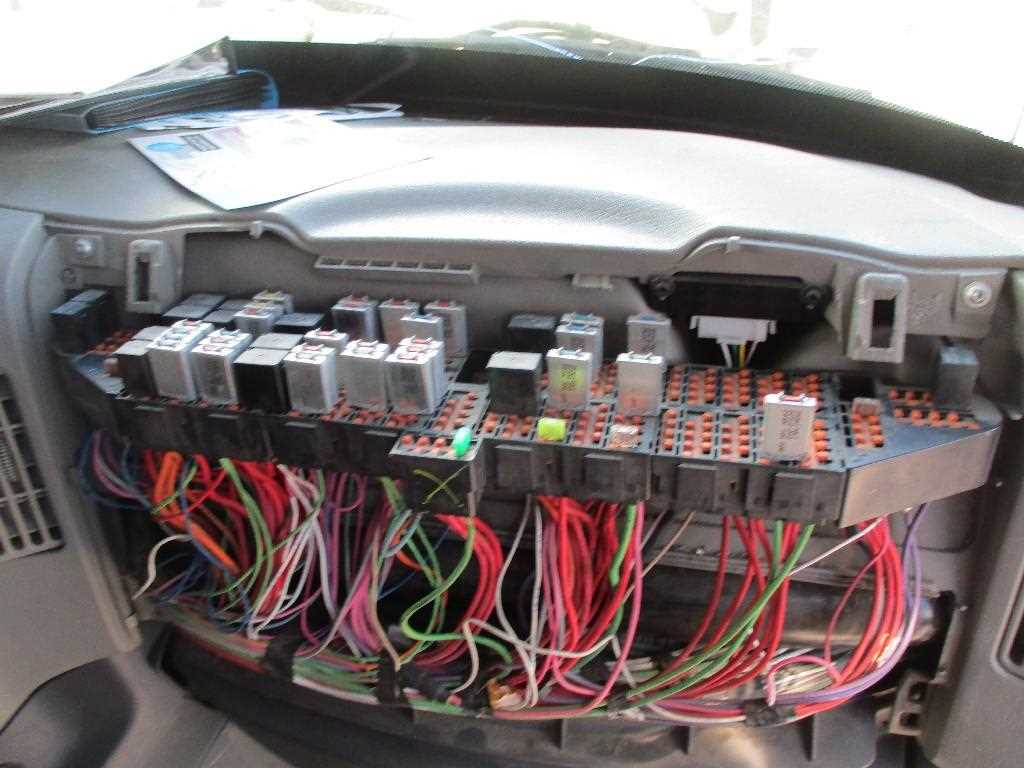

Heavy-duty vehicles are made up of numerous systems that work together seamlessly. These include the engine, transmission, suspension, electrical system, and braking mechanisms. Knowing where each part is located and how it connects with other components helps in diagnosing issues quickly.

How to Read Component Layouts

Reading and interpreting these layouts is an essential skill for anyone working with large trucks. The layout provides an organized view of the vehicle’s key components, showing their relationship to each other. Each section often includes labels, numbers, and references that make identifying and replacing parts easier.

Common Problems and Solutions

Vehicles with complex systems often face common issues such as electrical failures, fluid leaks, or worn-out components. Knowing how to locate and address these problems based on a clear component map can save time and reduce repair costs.

Maintenance Tips for Longevity

- Regular inspections are essential for detecting wear before it becomes a major issue.

- Replace parts as recommended by the manufacturer to maintain efficiency and safety.

- Lubrication of moving parts helps reduce friction and extend the life of your vehicle.

Proper upkeep ensures that the vehicle continues to perform optimally and avoids costly repairs down the road.

Understanding Vehicle Components and Maintenance

Maintaining a heavy-duty truck involves understanding the crucial systems and how they interconnect. Recognizing the layout and functions of various elements ensures effective troubleshooting and proper upkeep. Knowledge of these details is key to extending the vehicle’s lifespan and ensuring its safe operation on the road.

One of the first steps in working with any vehicle is becoming familiar with the schematic representation that outlines its key systems. These diagrams are essential for visualizing how different components fit together. Properly interpreting these visuals allows mechanics and owners to quickly identify areas in need of attention.

Common Issues and Solutions

With the complexity of modern trucks, certain problems tend to arise more frequently. Electrical malfunctions, engine inefficiencies, and worn components are common issues that can be identified through careful inspection. Understanding how each part interacts with the others helps pinpoint the source of problems more quickly, saving both time and resources.

Identifying and Replacing Faulty Components

Knowing how to replace faulty components is vital for maintaining the functionality of the vehicle. Clear reference materials help guide users through the process, ensuring the correct parts are replaced efficiently. This prevents the need for costly repairs and ensures that the truck stays operational without excessive downtime.

Long-Term Care and Maintenance

Regular maintenance is the best way to keep a vehicle running smoothly for years. Periodic checks of essential systems, such as the engine, transmission, and brakes, help detect potential problems early. Following the manufacturer’s recommendations and replacing worn-out parts at the right time is essential to preventing more serious issues down the line.