For those involved in vehicle recovery, understanding the key components that make up the machinery is crucial for efficient operation and maintenance. These systems rely on various intricate parts that work together seamlessly, ensuring smooth performance when lifting and towing vehicles. Familiarity with these elements helps technicians quickly identify issues and make necessary repairs.

In-depth knowledge of how each part functions is vital for anyone responsible for maintaining or repairing these machines. Recognizing the role of each component, whether it’s a hydraulic system, winch, or frame, can make a significant difference in ensuring long-term reliability and performance.

Proper understanding not only aids in troubleshooting but also ensures that the right spare parts are selected when replacements are necessary. This section will provide a detailed exploration of the essential parts that drive these systems, offering insights on how to read and interpret their configurations and functions.

Understanding Key Components of Towing Systems

Effective operation of a vehicle recovery system depends on understanding the core elements that contribute to its functionality. These essential units work in unison to ensure the smooth lifting, loading, and towing of vehicles. Gaining insight into the construction and roles of these components allows operators to ensure safety and optimal performance during use.

Core Units and Their Functions

Each element within the machinery has a specific role, from the hydraulic lifting mechanism to the winching system. Understanding how each unit operates and interacts with others is crucial for both efficiency and troubleshooting. Whether it’s the frame, cables, or motors, every component has a purpose that contributes to the overall function of the system.

Maintaining Optimal Performance

Regular inspection and maintenance of these core components ensure their longevity and proper functionality. Familiarity with how to identify wear and tear and when to replace or repair each unit is vital for minimizing downtime and preventing accidents. Keeping the system in peak condition relies on understanding how these essential units work together to provide safe and reliable towing service.

Essential Components in the Towing System

Every recovery vehicle relies on a series of interconnected units to ensure it can safely and effectively perform its duties. From lifting to securing, each component plays a vital role in the system’s overall performance. Understanding these essential units allows for more efficient operation and maintenance, helping to avoid potential issues during use.

Main Components

Several key units come together to form a fully functional recovery system. These are some of the most critical:

- Hydraulic Lifting Mechanism: Provides the power to raise and lower the vehicle.

- Winching System: Used for pulling and securing vehicles during recovery operations.

- Frame and Chassis: The foundation that supports the entire system and ensures stability.

- Transmission and Gearbox: Controls the movement and functionality of the entire system.

Supporting Elements

In addition to the core components, there are several supporting elements that enhance the system’s effectiveness:

- Control Systems: Allows the operator to control different aspects of the machinery.

- Braking and Safety Features: Ensures that the system operates safely under various conditions.

- Electrical Systems: Powers the lights, sensors, and other electrical parts essential for operation.

By understanding these critical units and how they work together, operators can ensure their system runs smoothly, minimizing downtime and maintaining efficiency.

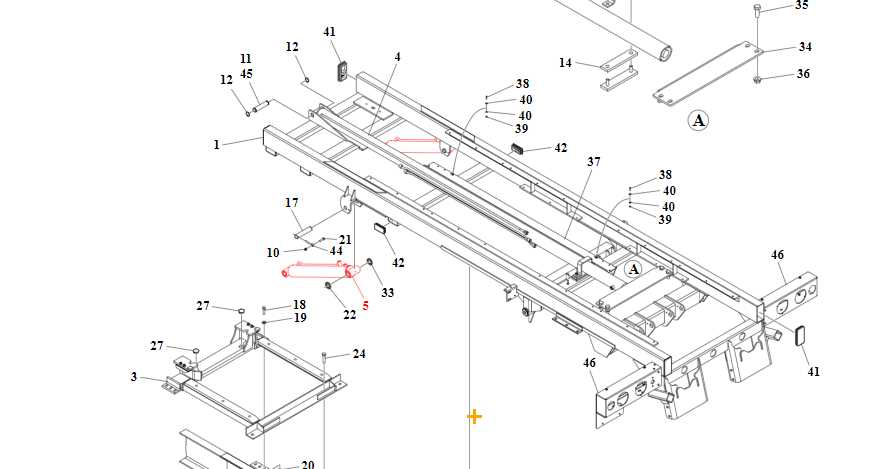

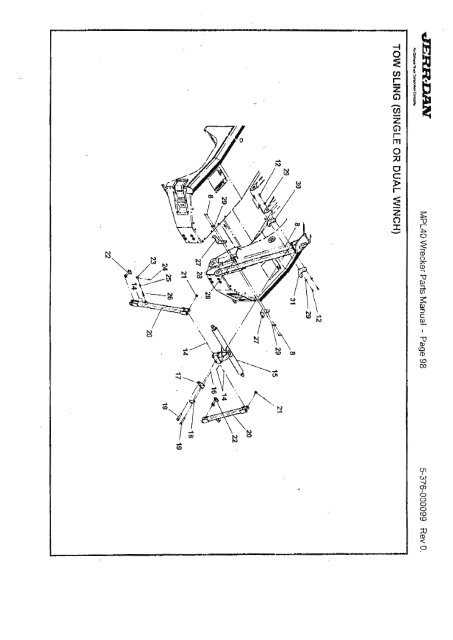

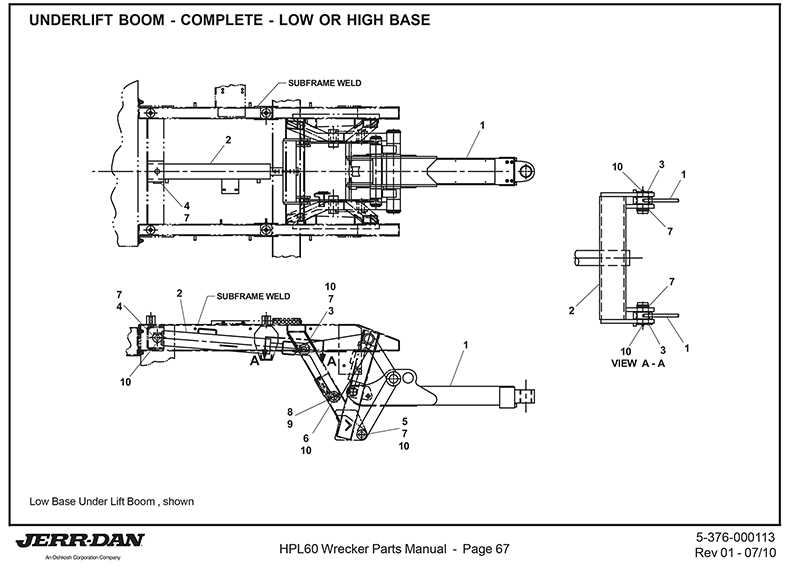

How to Read a Towing System Blueprint

Understanding the layout of a towing system is essential for anyone involved in maintenance or repairs. A detailed visual representation provides insight into the arrangement of components and their interconnections. By carefully studying these blueprints, you can gain a better understanding of the machine’s structure, functionality, and potential areas that may require attention.

To properly interpret these visuals, it’s important to know how to identify the various components, their labels, and the connections between them. Each section of the blueprint typically illustrates the mechanical and hydraulic systems in detail, showing how parts interact during operation.

Familiarizing yourself with the symbols used to represent different parts and functions will also help in quickly locating the relevant areas of the system. Pay attention to the reference numbers and legends, as these will direct you to the exact specifications and descriptions of each unit. Understanding this system of visual communication is crucial for effective troubleshooting and repairs.