When working with heavy-duty towing machinery, having a clear understanding of its structure and mechanisms is crucial for efficient operation. Knowing how each element functions ensures that maintenance and repairs can be performed accurately, extending the life of the equipment and improving performance.

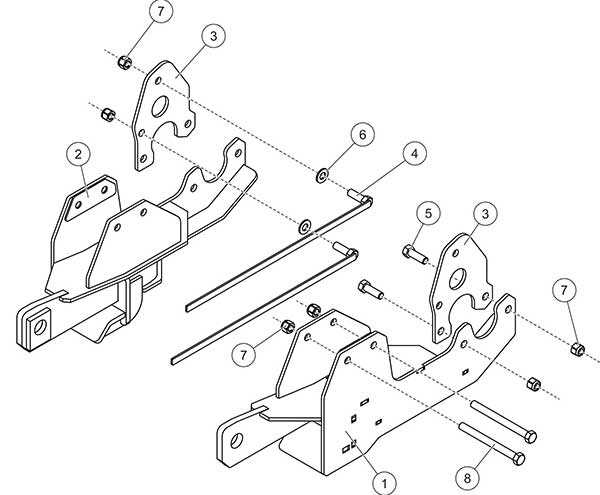

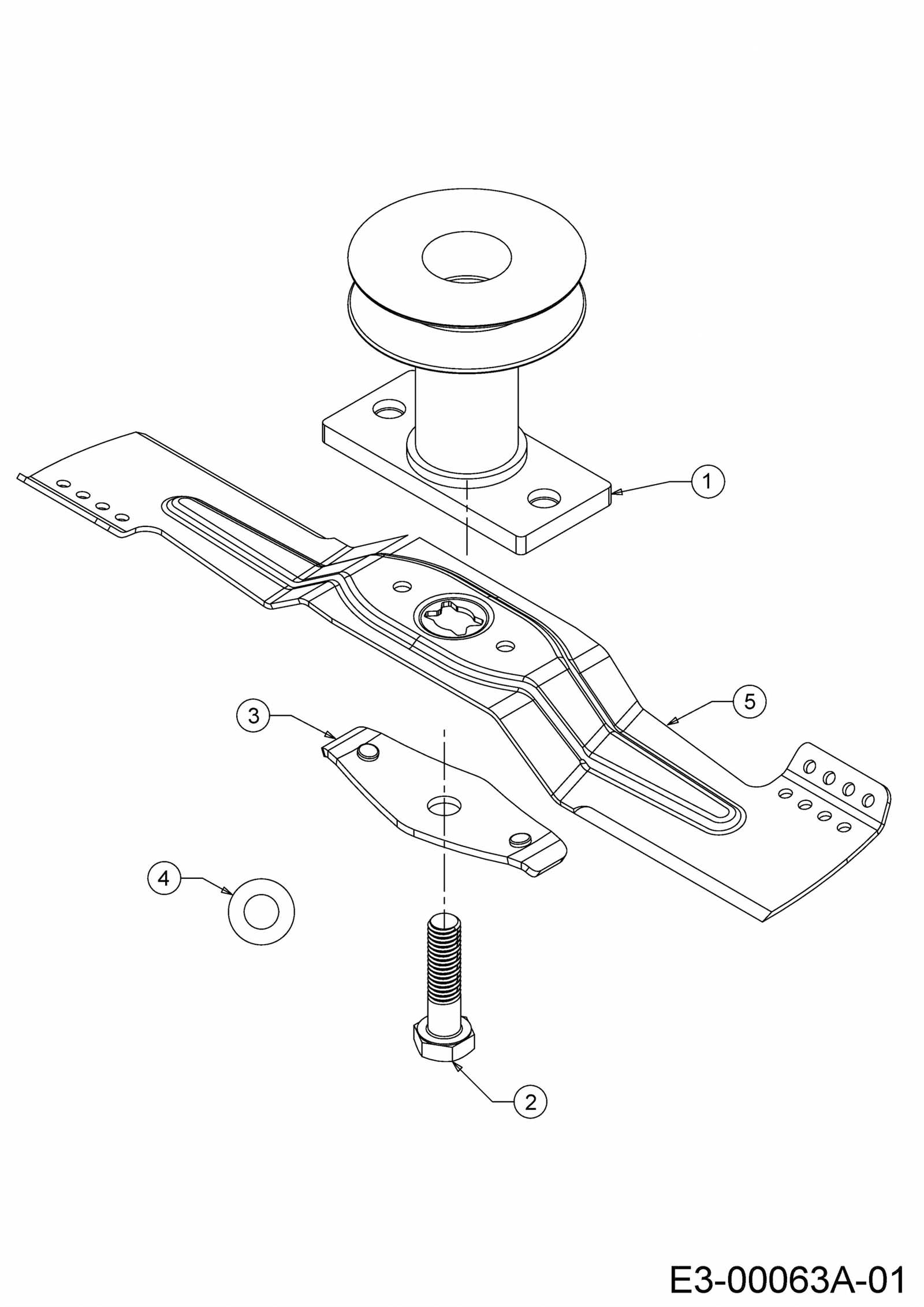

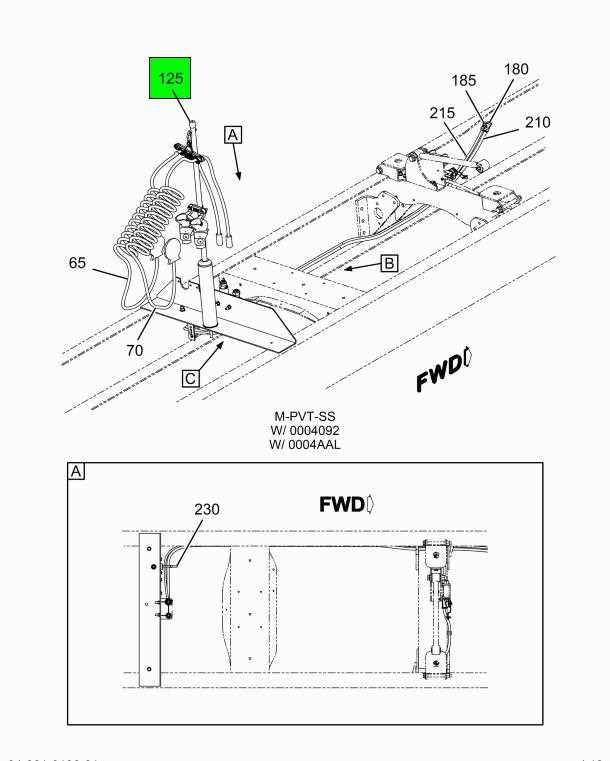

Detailed schematics play an essential role in visualizing the system’s components. These illustrations offer a comprehensive look at how different sections interact, making it easier to troubleshoot issues and replace worn-out parts when necessary. By studying these detailed visual guides, operators and technicians gain valuable insight into the overall system design.

Whether you are a technician or a towing professional, mastering the assembly will contribute to smoother workflows and greater reliability during operations. Embracing this knowledge is key to maintaining the machine in optimal condition.

Understanding Towing System Components

In any towing mechanism, each individual element plays a vital role in ensuring the system operates effectively. These machines are composed of various interconnected sections, each designed to perform specific tasks that contribute to the overall functionality. A deeper understanding of these components is essential for proper handling, maintenance, and repair.

Key Elements of the System

The machinery consists of a series of critical components that enable the movement and secure handling of vehicles. From the primary lifting mechanism to the hydraulic systems and control levers, each part works in harmony to support heavy loads. Familiarity with these parts helps in diagnosing issues quickly and efficiently, saving time and resources.

Functionality and Interaction

Understanding how the different elements interact is key to maximizing the effectiveness of the equipment. For instance, the hydraulic system plays a major role in providing the necessary force, while the control mechanisms allow operators to maneuver with precision. Knowing the relationship between these parts is fundamental for ensuring optimal performance during use.

How to Read the Parts Diagram

Understanding the schematic of a towing system is essential for proper maintenance and repairs. These visual guides provide a detailed view of how the various components are arranged and connected. By learning to interpret these illustrations, operators can quickly identify issues and find the correct replacement parts.

Each section of the drawing is labeled to correspond with a specific component, and the lines between them show how they are linked. Familiarizing yourself with the symbols and labels used in these schematics is key to navigating the document effectively. This knowledge allows you to pinpoint the precise locations of components and understand their functions within the overall mechanism.

Maintaining Towing Systems

Regular upkeep of a heavy-duty vehicle handling system is essential to ensure its longevity and optimal performance. Routine checks and timely repairs prevent breakdowns and enhance the overall efficiency of the machinery. A well-maintained system not only reduces downtime but also guarantees safety during operation.

Routine Inspection and Troubleshooting

Performing periodic inspections helps to identify early signs of wear or malfunction. Pay close attention to the most stressed parts of the mechanism, such as the hydraulic lines, control systems, and moving components. Catching small issues early on can save time and costs associated with major repairs.

Proper Maintenance Practices

Effective maintenance practices involve cleaning, lubrication, and replacement of worn components as necessary. Ensuring that the system remains free from debris and that all moving parts are properly lubricated will keep the system running smoothly. Regularly checking the fluid levels and adjusting pressure settings are also crucial steps in maintaining performance.

Staying on top of maintenance tasks ensures that the system remains reliable, reducing the chances of unexpected breakdowns and extending its operational lifespan.