When it comes to maintaining outdoor machinery, a thorough understanding of each component is crucial for ensuring longevity and optimal performance. By familiarizing yourself with the individual parts and their functions, you can quickly address issues that arise during use. Proper maintenance starts with the ability to identify and assess the condition of each piece.

Recognizing the importance of each element within your tool system is the first step in troubleshooting and repair. Whether you are a seasoned user or new to handling these devices, knowing how to pinpoint problems can save you both time and money. With the right knowledge, even the most challenging maintenance tasks become manageable.

In this guide, we will break down the essential components of your machine and provide you with the insights needed to make informed decisions. Whether you are looking to replace a worn-out part or simply want to ensure everything is in top condition, this article will serve as your go-to resource for understanding the inner workings of your equipment.

Understanding Key Components of Your Outdoor Tool

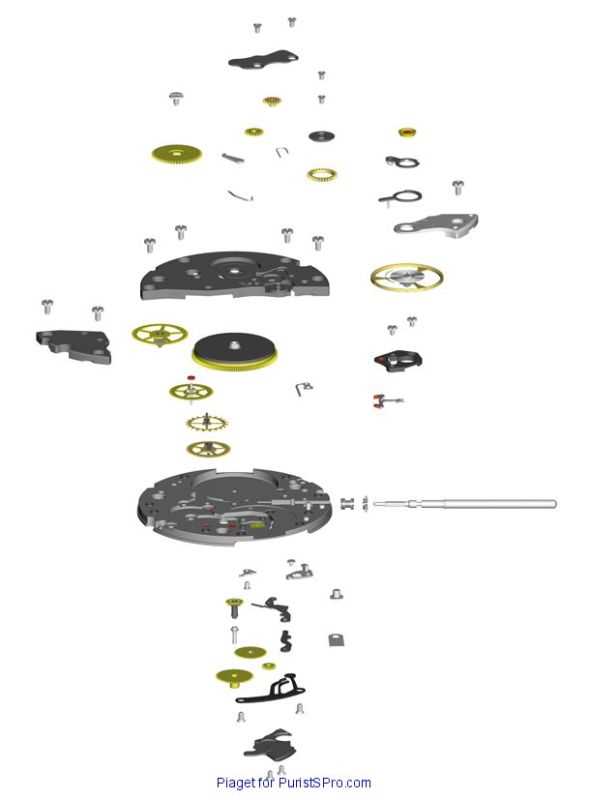

To ensure the effective operation of your outdoor tool, it is essential to have a clear understanding of the different components that make it function. Each element plays a specific role in the overall performance and longevity of the equipment. From the main drive mechanism to the smaller, often overlooked parts, familiarity with each piece will enable you to troubleshoot issues and perform regular maintenance with ease.

The Main Drive System

The main drive system is the heart of the machine, responsible for powering the entire operation. This includes the motor, which is the engine behind all functions, and the mechanism that converts power into motion. Maintaining this part is crucial for ensuring reliable and consistent performance. Regular checks and timely repairs can prevent malfunctions during use, allowing you to stay focused on your tasks.

Supporting Mechanisms and Attachments

Other supporting components such as the handles, trigger systems, and fuel connections all play an important role in user control and efficiency. The handles provide stability and ease of use, while the trigger systems allow for precise control over power delivery. Ensuring these elements are well-maintained is key for a smooth operation, as any malfunction can affect the tool’s handling and safety.

Regular inspection of these components, especially after frequent use, will help in identifying potential issues before they become major problems. Taking the time to understand how each part works and interacts can help extend the lifespan of your equipment and improve your overall experience.

How to Read the Equipment Breakdown Guide

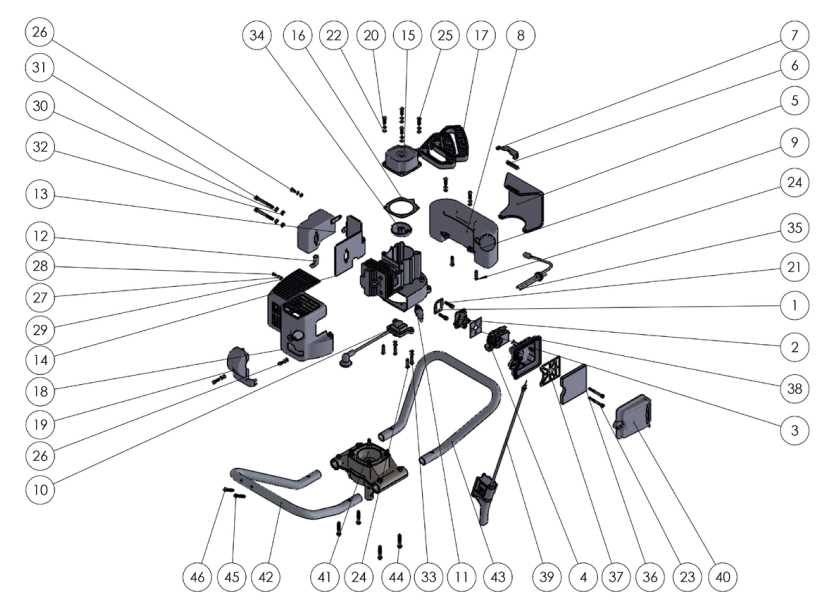

Understanding how to interpret an equipment breakdown guide is essential for efficient maintenance and repair. A clear visual representation of the various components helps users identify each part, locate potential issues, and make informed decisions about repairs or replacements. Familiarizing yourself with these guides will streamline the troubleshooting process and improve your ability to perform basic repairs.

Key Elements of a Breakdown Guide

When looking at a breakdown guide, it is important to focus on several key aspects that will help you understand the layout and labeling system:

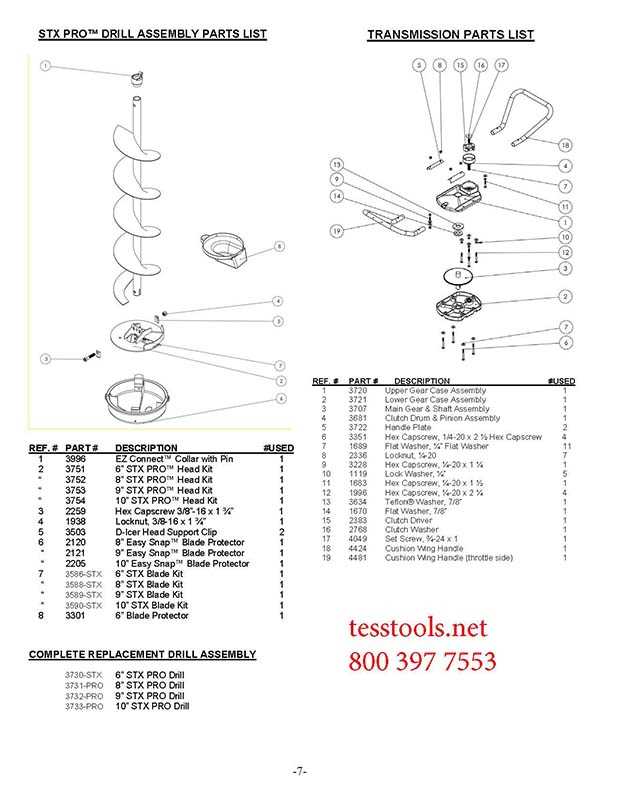

- Component Labels: Each part is typically labeled with a unique identifier or number. These labels help you quickly find the corresponding part in manuals or when ordering replacements.

- Visual Representation: The image or illustration shows each part’s location and how it fits within the whole system. This allows you to pinpoint specific parts that may need attention.

- Connections and Interactions: Understanding how different parts connect and function together helps in diagnosing issues related to performance or wear.

Using the Guide for Maintenance and Repair

Once you have identified the relevant components in the breakdown guide, it’s easier to address problems when they arise. Follow these steps:

- Locate the part that appears worn or damaged based on symptoms or performance issues.

- Refer to the label or identifier to confirm the part number for accurate replacement.

- Check for any additional instructions or notes in the guide about installation, removal, or maintenance.

- If necessary, order the part and replace it following the step-by-step guidance provided in the breakdown.

By regularly referring to the breakdown guide, you can ensure all components are functioning properly and address any potential problems early on, preventing larger issues in the future.

Common Issues with Outdoor Drilling Equipment

Even the most reliable outdoor tools can encounter issues over time due to regular wear and tear. Understanding the most common problems that arise can help users address these issues quickly and efficiently, reducing downtime and ensuring continued performance. Identifying the symptoms early allows for timely repairs and the prevention of further damage.

One frequent problem is the machine’s inability to start or function properly, which can be caused by various factors such as fuel line blockages, faulty ignition systems, or motor malfunctions. Another issue is reduced cutting power, often linked to dull blades or an improperly calibrated drive system. Users may also notice inconsistent operation, which could be due to loose connections or damaged components that affect stability and power transmission.

Additionally, problems with the control mechanisms, such as unresponsive triggers or faulty throttle systems, can lead to difficulties in managing the device’s operation. These issues can often be traced back to simple causes, such as wear or improper maintenance, but may sometimes require more in-depth repairs to restore full functionality.

Regular inspection and maintenance are key to preventing these common problems. By staying aware of these potential issues and addressing them promptly, you can prolong the life of your equipment and ensure it performs at its best when needed most.