For any tractor owner or mechanic, knowing the layout of critical components is essential for proper maintenance and troubleshooting. Having a clear visual guide of all the major elements ensures quick identification and more efficient repairs.

Whether you’re dealing with mechanical failures or performing routine checks, understanding how each part fits together helps to streamline the process. A comprehensive map of the equipment offers clarity and reduces the chances of errors during repairs.

Effective management of these complex systems starts with accurately locating and understanding each part. This knowledge not only boosts performance but also extends the lifespan of the machine.

Understanding the Tractor Layout

Having a clear understanding of a tractor’s layout is crucial for effective maintenance and troubleshooting. The design of these machines is intricate, with each component playing a specific role in ensuring smooth operation. A well-organized visual representation of these elements allows for quick identification and streamlines repair processes.

Key Systems and Functions

The tractor consists of several major systems that work together to provide power and control. These include the engine, transmission, hydraulics, and steering components. Each system is connected in a way that maximizes efficiency, and recognizing their locations can save valuable time when diagnosing issues or performing upgrades.

How to Read the Layout Effectively

Familiarity with the layout enables operators to spot problems early and address them before they become serious. Knowing the position of critical components helps in performing routine maintenance, ensuring that each part functions properly. A detailed view of the entire system also helps identify areas where parts may need to be replaced or serviced.

Key Components of the Tractor

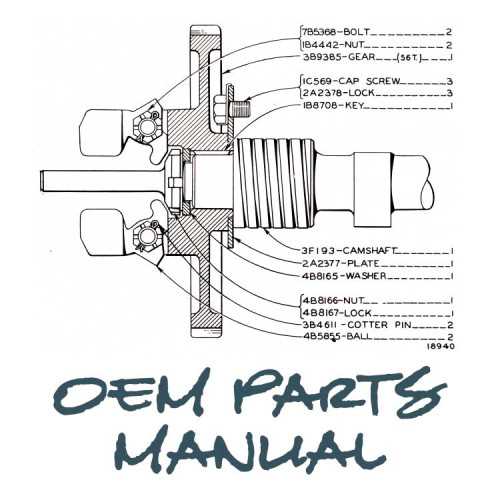

A thorough understanding of the essential components of a tractor is vital for its optimal performance and longevity. These key elements work together to provide power, maneuverability, and functionality, each serving a unique purpose. Recognizing how they interconnect is crucial for any repairs or maintenance tasks.

Engine and Power Transmission

The engine is the heart of the machine, providing the necessary power for all operations. It is connected to the transmission system, which transfers the energy to various components. This system ensures that the tractor can operate efficiently, whether in high-load situations or during routine tasks. The transmission’s durability is essential for the smooth transfer of power to the wheels and implements.

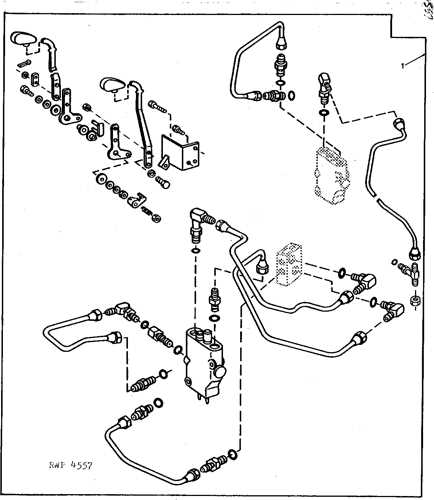

Hydraulic System and Steering

Hydraulics play a significant role in controlling movement and enabling attachments to function. This system operates various mechanisms, from lifting heavy equipment to controlling steering. Proper maintenance of hydraulic components ensures optimal performance. Additionally, the steering system, which is often powered by hydraulic pressure, allows precise control for maneuvering the vehicle with ease in tight spaces or rough terrain.

How to Use the Component Layout

Effectively using a visual guide of the machine’s layout can significantly improve the efficiency of repairs and maintenance. By referencing this detailed map, operators and technicians can quickly locate and identify key elements, ensuring the right actions are taken. A proper understanding of this tool simplifies tasks, making it easier to resolve issues without wasting time.

Step-by-Step Identification

Start by identifying each component within the layout. The visual guide will highlight crucial sections such as the engine, transmission, and hydraulic systems. By understanding the flow and interconnections between these elements, it becomes easier to pinpoint areas that may require attention or replacement.

Streamlining Maintenance and Repairs

Routine checks become more manageable when you are familiar with the machine’s structure. This map helps you focus on specific areas that need monitoring or servicing. Being able to refer to the guide when troubleshooting also allows for a quicker resolution to any problems that may arise during operation, reducing downtime and improving overall efficiency.