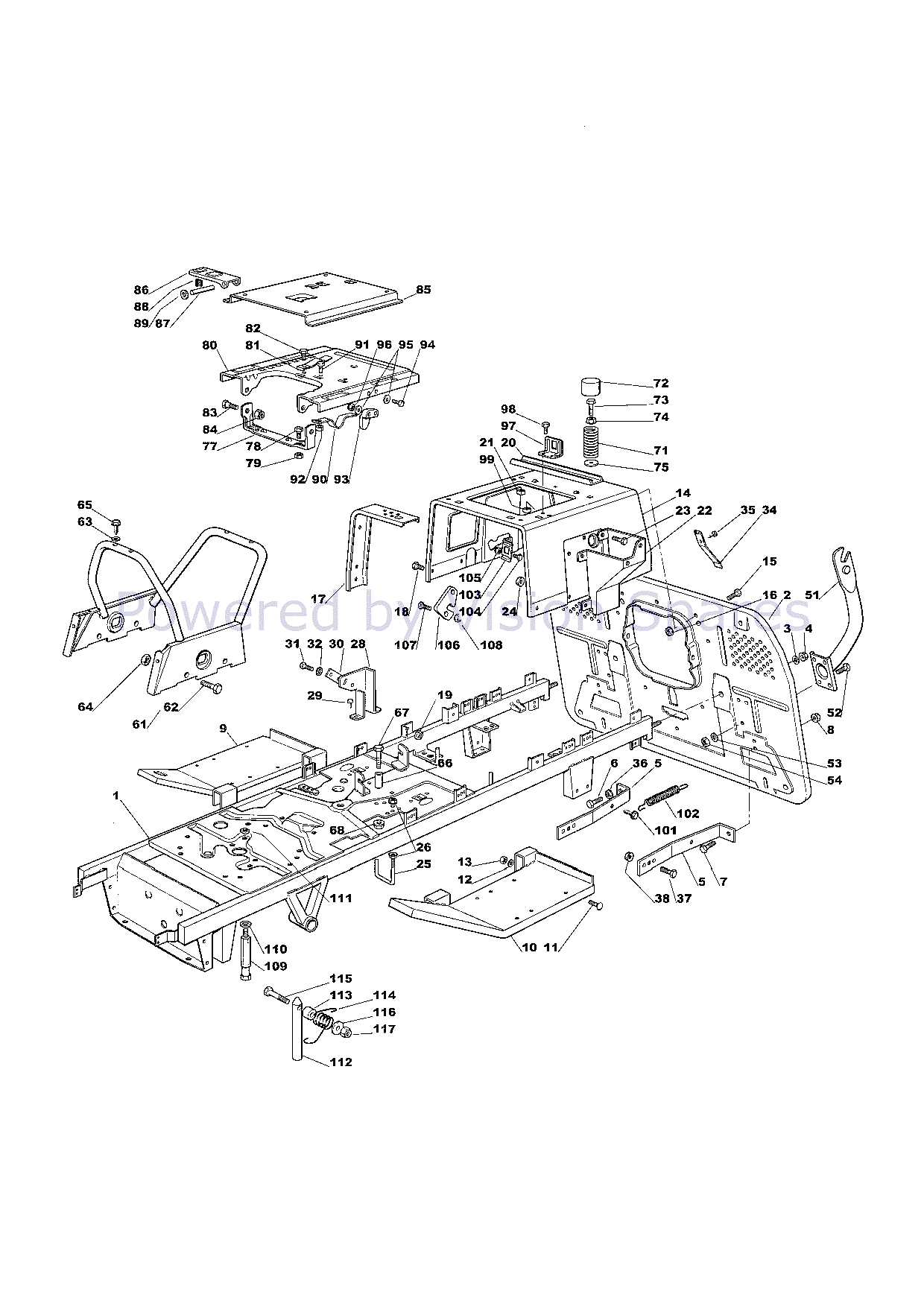

For anyone involved in the maintenance or repair of agricultural machinery, having a clear and detailed visual representation of the components is essential. Knowing where each part fits and how it interacts with others can significantly streamline troubleshooting and maintenance processes.

Accurate identification of components helps in efficient repairs, preventing unnecessary mistakes and ensuring that equipment runs smoothly for longer periods. Whether it’s replacing a worn-out part or performing regular check-ups, a clear guide is invaluable.

This section offers an in-depth look at how such diagrams assist in making repairs easier and more effective. By breaking down the machine into understandable sections, it becomes much easier to pinpoint specific areas that require attention or improvement.

Understanding the John Deere 116 Parts Diagram

A comprehensive breakdown of machinery components is essential for effective troubleshooting and maintenance. Having a clear overview of how each element interacts within the system can save time and effort when diagnosing issues or performing repairs.

Visual guides offer a structured way to identify each component’s role, ensuring that repairs are done with precision and without unnecessary disassembly. Properly understanding how the system is organized enables technicians to pinpoint problems quickly, reducing downtime.

These guides are particularly useful when dealing with complex machines, where knowing each part’s exact location and function is crucial for smooth operation. By referring to an organized schematic, operators can proceed with confidence, knowing they have the correct replacement components or tools.

How to Use the Parts Diagram Effectively

Using a visual guide to understand the components of a machine can significantly enhance maintenance efficiency. Knowing how to read and interpret such a guide ensures that every part is properly identified, reducing errors and increasing the accuracy of repairs.

Start by familiarizing yourself with the overall layout of the machine. Understand the different sections and how they interact. This step is crucial before diving into specific components or issues, as it provides context for the entire system.

Pay attention to labels and annotations provided in the guide. These often contain valuable information such as part numbers, placement details, and installation instructions. Accurate interpretation of these elements ensures that replacements and adjustments are made correctly, improving the overall reliability of the machine.

Common Repairs and Replacements for John Deere 116

Over time, machinery components may wear out or become damaged due to regular use. Understanding which parts are most prone to issues can help owners proactively address potential problems, minimizing downtime and repair costs.

Engine components often require attention, especially in older models. Regularly checking the belts, spark plugs, and filters can prevent major failures and ensure smooth operation. Timely replacement of these parts helps maintain optimal performance and extends the lifespan of the machine.

Another common area that may need servicing is the drivetrain. Parts such as gears, bearings, and shafts often experience wear and tear, especially with frequent use. Replacing these components as soon as signs of wear appear can prevent more serious damage and costly repairs down the line.