Understanding the structure and functionality of your machinery is essential for efficient operation and maintenance. Knowing the specific components and how they interact allows for better troubleshooting and longer-lasting performance. This guide will help you navigate through essential details related to your equipment, offering insights into its key elements.

Familiarizing yourself with the internal layout can greatly improve your ability to identify issues early, make repairs, and maintain the vehicle in optimal condition. With a clear understanding of each section, you can handle maintenance tasks with confidence.

By the end of this guide, you will have a comprehensive understanding of how to interpret complex schematics, identify possible areas of concern, and ensure smooth operation of your machine.

Understanding the Key Equipment Components

Proper knowledge of your machinery’s essential components plays a vital role in ensuring effective operation and maintenance. Every vehicle or machine is made up of interconnected parts that work together, making it crucial to understand each part’s role and function. This section will break down the core elements, helping you gain a deeper insight into how the system functions as a whole.

Core Elements of the Machine

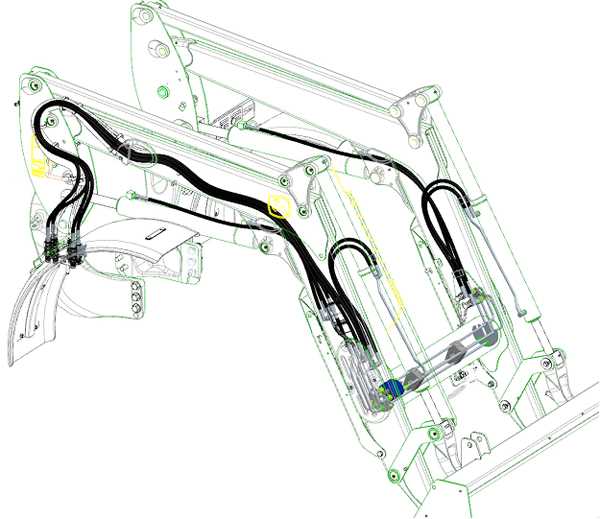

- Hydraulic System – A powerful system that controls various functions, from lifting mechanisms to other moving parts. Understanding its components is key to smooth performance.

- Drive Train – Responsible for transferring power from the engine to the wheels, ensuring the machine moves efficiently.

- Frame and Chassis – The foundational structure that supports all other components and absorbs operational stresses.

Identifying and Maintaining Critical Components

It’s essential to stay aware of each component’s condition and potential issues. Proper care for each part can lead to extended lifespans and prevent unnecessary breakdowns. Regular inspections can help identify:

- Wear and tear in moving parts

- Leaks or blockages in hydraulic systems

- Signs of stress or cracks in structural components

By familiarizing yourself with these fundamental elements, you’ll be better equipped to troubleshoot and perform necessary repairs, ensuring optimal machinery performance over time.

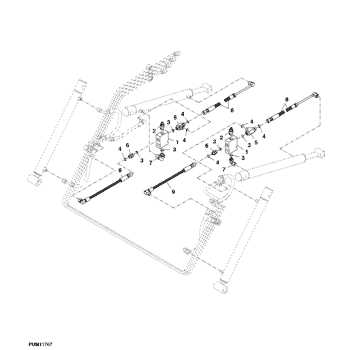

How to Read the Schematic Effectively

Interpreting technical schematics is essential for understanding the layout of a machine’s components. These visual guides provide a clear and organized representation of how various elements are connected and function together. Knowing how to read these diagrams will enable you to identify parts, understand their roles, and troubleshoot more efficiently.

Start by familiarizing yourself with the overall structure of the schematic. Look for the following key features:

- Legend and Symbols – These usually appear at the corner of the schematic, providing definitions for the icons and notations used.

- Part Numbers – Each component is assigned a unique identifier, allowing you to match it with physical components and order replacements.

- Connections – Lines and arrows will show how components are linked, often indicating the flow of energy or materials.

Once you have a grasp of these basic elements, focus on specific areas of interest. Whether you’re looking to replace a broken component or verify a connection, understanding how to follow the flow of the schematic will make the process much easier.

Common Issues and Solutions for Equipment Components

Even with proper maintenance, machinery can sometimes experience issues that affect its performance. Recognizing these problems early and understanding potential solutions can save time and prevent costly repairs. This section covers some of the most common challenges faced by operators and offers practical solutions for fixing them.

Hydraulic Leaks are one of the most frequent problems that can arise, often caused by damaged seals or hoses. If you notice a decrease in lifting power or fluid on the ground, inspect the hydraulic lines carefully for cracks or wear. Replacing damaged seals or hoses promptly will restore functionality.

Worn Drive Components can cause sluggish or inconsistent movement. Over time, parts like belts and gears may wear down, leading to inefficiency. Regular inspection of these components, especially for signs of fraying or misalignment, will help you catch issues before they worsen. Replacing worn parts ensures smoother operation.

Structural Fatigue can result from continuous stress, especially when the equipment is used for heavy-duty tasks. If you detect cracks or bends in the frame, immediate reinforcement or replacement may be required to maintain safety and operational integrity.

By addressing these common concerns promptly, operators can maintain the efficiency and lifespan of their machinery, ensuring that it performs optimally for years to come.