For effective machinery maintenance, it’s essential to have a clear understanding of its internal structure. Knowing the layout of key components allows operators to identify parts that may need attention, making repairs more efficient and preventing breakdowns. A well-documented schematic serves as a useful tool for troubleshooting and ensures that every piece is correctly maintained or replaced when necessary.

Proper knowledge of how the various components interact with each other can significantly reduce downtime and maintenance costs. This guide will help you navigate the different sections of the equipment, providing detailed information to ensure optimal performance. Understanding the specific functions of each part is crucial for maintaining the longevity of the machine and avoiding costly repairs.

Understanding the Equipment Components

Each machine is made up of a network of individual elements, each performing a specific function. Recognizing how these parts work together ensures that operators can troubleshoot issues effectively and maintain optimal performance. A thorough grasp of the key elements is essential for smooth operation and avoiding unexpected failures.

Key Structural Elements

The primary components that make up the structure of any heavy machinery include the frame, engine, hydraulic systems, and transmission. These elements form the backbone of the machine, and understanding their roles is critical for identifying potential issues. The frame supports the entire assembly, while the engine provides the necessary power for movement. Hydraulic systems manage fluid dynamics to perform various tasks, and the transmission controls the speed and direction of movement.

Auxiliary Systems and Features

In addition to the core components, machines often include auxiliary systems such as cooling units, electrical systems, and safety mechanisms. These parts work together to ensure smooth functionality, prevent overheating, and protect the machine from damage. A malfunction in any of these supporting systems can lead to reduced efficiency or even cause a breakdown, making their proper maintenance essential.

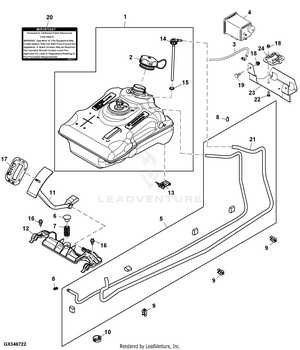

Step-by-Step Guide to Components Layout

Understanding the layout of a machine’s internal elements is essential for proper maintenance and repair. A detailed guide can help you identify each part’s location and function, enabling more efficient troubleshooting. By following a structured approach, you can locate and address issues with accuracy, reducing downtime and ensuring smooth operation.

Locating Key Assembly Sections

The first step in navigating the schematic is identifying the main sections of the machine. Begin by focusing on the powertrain, which includes the engine, transmission, and driveline. These sections are often interconnected, so understanding their relationships helps in diagnosing performance issues. Once you’ve identified these key components, move on to auxiliary systems such as the hydraulic and cooling systems.

Identifying Specific Elements for Replacement

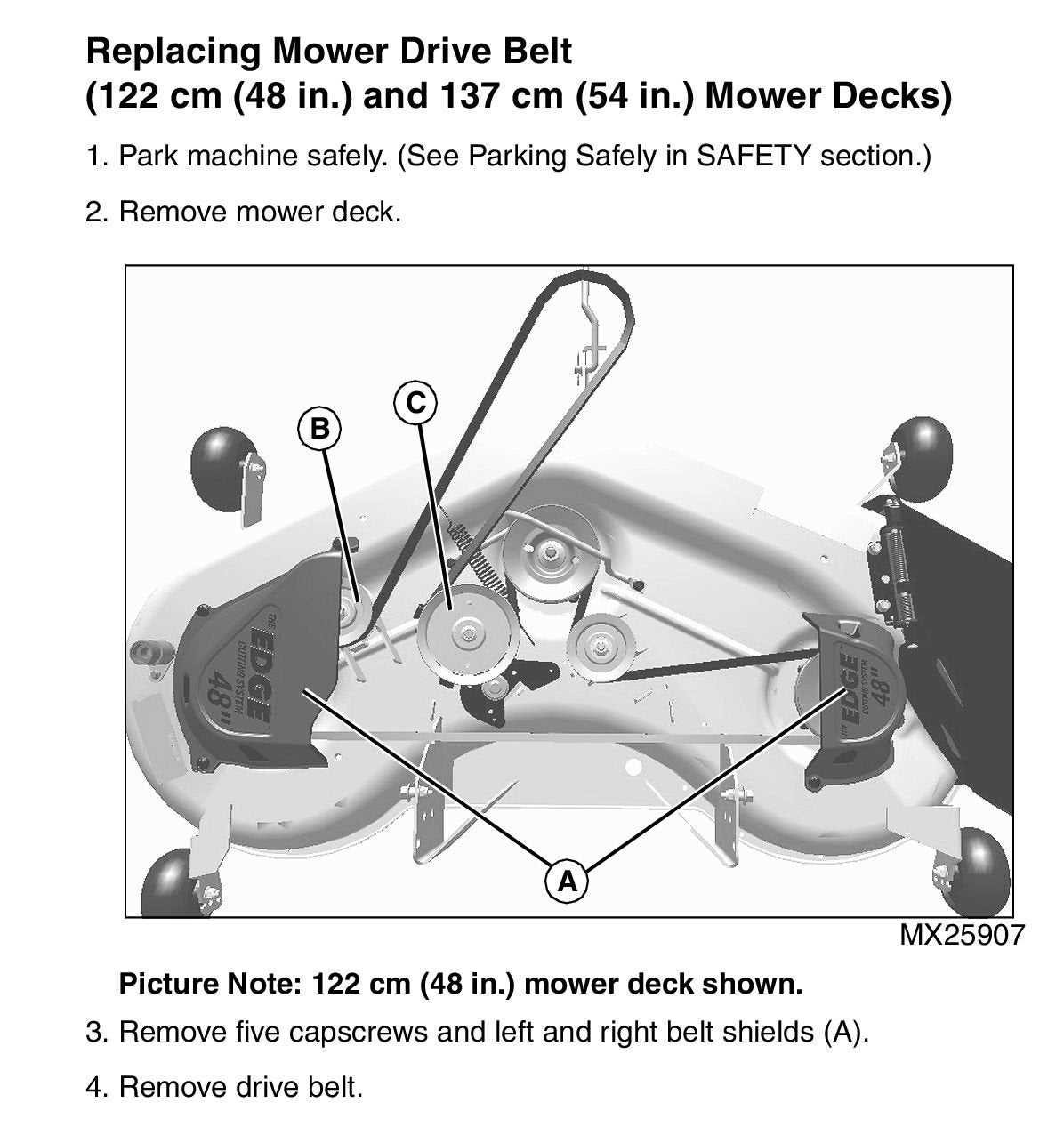

Once you have the layout mapped out, pinpoint the exact parts that require replacement or maintenance. Pay close attention to wear indicators and components prone to regular failure, such as belts, filters, and seals. By following the guide step by step, you can quickly identify faulty parts and replace them to restore optimal function. This will save both time and money in the long run, as repairs can be done before issues escalate.

Common Issues and Part Replacements

Machines are subject to wear and tear over time, leading to common malfunctions that can hinder performance. Identifying these frequent issues early on can prevent larger problems and help maintain optimal functionality. Regular maintenance and timely part replacements are essential to extend the lifespan of the equipment and reduce costly repairs.

Engine and Transmission Issues

The engine and transmission are the heart of any heavy-duty equipment, and problems in these areas can lead to significant performance drops. Common issues include overheating, loss of power, and irregular shifting. Regularly inspecting these components and replacing worn-out filters, seals, and fluid can prevent these problems. Replacing the engine coolant and ensuring proper lubrication are key actions that help maintain efficiency and avoid engine failure.

Hydraulic System Failures

Hydraulic systems are prone to leaks and malfunctions due to pressure buildup and wear on hoses or seals. These issues can cause a loss of functionality, resulting in slower movements or complete failure of certain operations. Replacing worn-out hydraulic hoses, filters, and fluid regularly is critical for maintaining the proper function of this system. Keeping hydraulic components clean and inspecting for damage regularly will ensure that your machinery operates smoothly and safely.