When it comes to maintaining agricultural machinery, having a clear visual representation of its structure is essential. A detailed layout can guide users through the various sections, ensuring they can identify components with ease. This approach is crucial for both troubleshooting and general upkeep.

Such representations often serve as a vital tool for mechanics and operators alike, simplifying complex tasks like assembly and repairs. By breaking down machinery into smaller, more manageable parts, it becomes possible to target specific areas that may require attention.

Accurate identification of each part is key to preventing damage and ensuring the equipment runs smoothly. By understanding how each element functions within the larger system, users can make more informed decisions about maintenance and repair actions. This not only increases efficiency but also prolongs the lifespan of the machinery.

Key Components of John Deere 2240

Understanding the primary elements of any agricultural machine is essential for effective operation and maintenance. Each component plays a vital role in ensuring the overall functionality of the equipment. Whether it’s the engine, transmission, or hydraulic system, each section needs to be well-understood to ensure smooth performance and longevity.

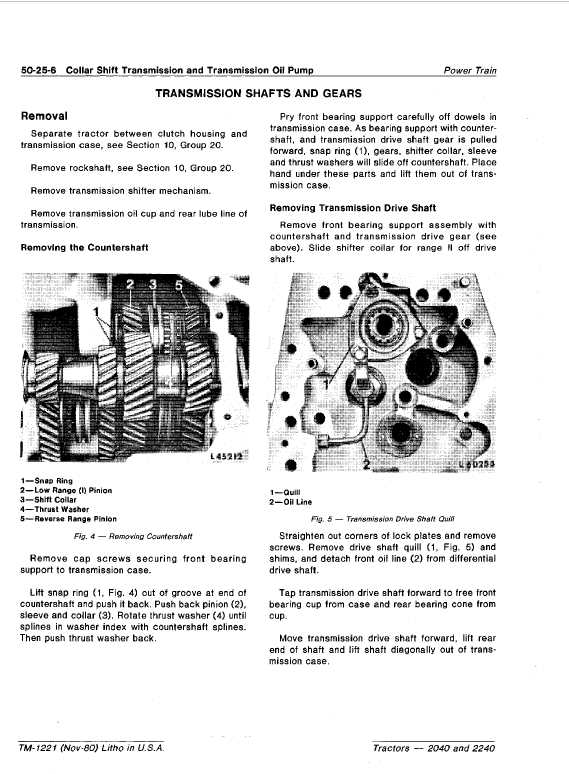

Engine and Powertrain

The engine serves as the heart of the machinery, providing the power necessary for all functions. The powertrain connects the engine to other critical parts, including the wheels and other drive mechanisms. Proper maintenance of these components ensures consistent performance and avoids unnecessary breakdowns.

Hydraulic System

The hydraulic system is another crucial part of the machinery, enabling various functions like lifting and steering. Regular inspection of the pumps, cylinders, and hoses is vital for keeping this system running efficiently. Ensuring that fluid levels are correct and that there are no leaks can prevent many common issues.

Understanding the John Deere 2240 Assembly

Grasping how the various components of a machine fit together is crucial for anyone working with heavy-duty equipment. The assembly process is more than just a simple connection of parts; it involves ensuring that each element is aligned correctly for optimal performance. From the frame to the attachments, understanding the assembly layout helps in both repairs and routine maintenance.

Frame and Chassis

The frame forms the foundation of the machinery, supporting all other components. It is essential that the frame is properly aligned and that all connections are secure. This ensures the stability of the entire system, allowing for effective operation, even under heavy loads. Maintenance of this section includes checking for any signs of wear or damage.

Engine and Transmission Integration

The engine and transmission work together to provide the power needed for movement and operation. Proper integration between these components is essential for smooth operation. Ensuring that the connections are tight and the components are regularly serviced helps prevent unnecessary stress on the system, reducing the risk of failure.

How to Use the Parts Diagram

Utilizing a visual reference for a machine’s components can significantly streamline the maintenance and repair processes. A well-constructed visual map of a machine’s structure helps users quickly identify specific elements that need attention. It allows for an efficient approach to diagnosing issues and performing tasks, from simple repairs to full system overhauls.

To effectively use such a reference, begin by familiarizing yourself with the overall layout. This will help you understand the relationship between the different sections and how they interact. Once you have an understanding of the general setup, focus on identifying the individual parts by their labels or numbers to locate the necessary components for replacement or inspection.

Regularly consulting this resource during maintenance tasks ensures that all components are correctly assembled and functioning. It also assists in identifying wear or damage early, preventing more serious issues from arising. With practice, using these references becomes an indispensable skill for anyone working with heavy machinery.