When maintaining complex agricultural machinery, it’s essential to have a clear understanding of the various elements that make up its system. A comprehensive visual representation of these components can help users navigate maintenance and troubleshooting tasks with ease. Knowing where each piece fits and its specific function can significantly improve operational efficiency and minimize downtime.

Effective machine upkeep begins with knowing the layout of the components that drive its functionality. Whether it’s for routine maintenance or during unexpected repairs, having access to an accurate representation allows users to quickly identify any issues and address them before they escalate. This guide will walk you through essential details of the machine’s core components and how they interact.

Proper maintenance relies on understanding the intricate relationships between all parts, making it easier to manage your equipment’s health and longevity. Whether you’re an experienced operator or new to the field, familiarizing yourself with the system can make all the difference when it comes to keeping the equipment running smoothly.

Key Components of Agricultural Equipment

Understanding the fundamental components of agricultural machinery is crucial for ensuring optimal performance. These systems consist of various essential elements, each contributing to the smooth operation of the equipment. Identifying and maintaining each part is vital for extending the life of the machine and preventing unexpected failures during operation.

Critical Mechanical Systems

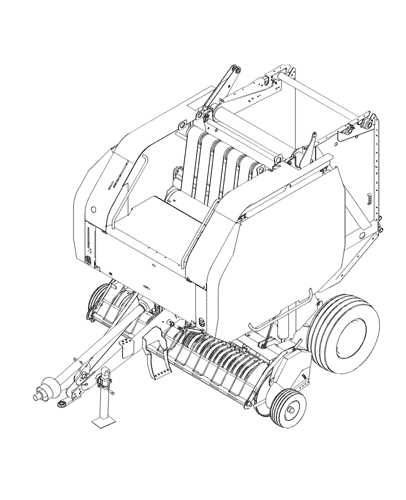

Among the most important systems are those that drive the machine’s ability to collect and process material efficiently. These mechanical components include the feeding mechanism, the compression system, and the output assembly, all working together to ensure proper handling of materials. Regular inspection and upkeep of these systems are necessary to avoid unnecessary wear and tear, which could disrupt functionality.

Hydraulic and Electrical Components

Hydraulic systems play a key role in powering several critical functions, such as lifting and adjusting different parts of the machine. These systems require routine checks for leaks, pressure imbalances, and other issues that might affect performance. Additionally, electrical systems control various automated features that ensure proper operation and ease of use. Proper maintenance of these components prevents malfunctions and ensures the equipment remains reliable over time.

Understanding Maintenance for Agricultural Equipment Components

Proper maintenance is essential to ensure the long-term efficiency and reliability of machinery. A proactive approach to servicing individual components not only prevents breakdowns but also maximizes the performance of each system. Identifying key areas for maintenance and understanding their role within the larger mechanism is crucial for maintaining operational stability.

Routine Inspections and Lubrication

One of the most important aspects of machine upkeep is performing regular inspections. Checking for wear and tear, loose connections, or damaged components ensures that potential problems are identified early. Additionally, lubricating moving parts helps to reduce friction, preventing unnecessary wear and ensuring smooth operation. This simple step can significantly extend the lifespan of the equipment.

Adjustments and Calibration

In addition to inspections, adjusting certain components is crucial for maintaining peak performance. Components such as tensioners, feed systems, and pressure regulators require periodic adjustments to keep everything functioning properly. Calibration ensures that the machinery operates within its optimal parameters, preventing overuse of certain parts and promoting uniform efficiency across the system.

How to Identify Components in the Layout

Recognizing the components within a mechanical layout can be challenging without a clear understanding of each element’s role. A well-organized schematic offers a visual representation of all the key parts, helping users understand their positions and connections. Familiarity with the structure allows for quicker identification when troubleshooting or performing maintenance tasks.

The first step in identifying components is to familiarize yourself with the general layout. Each section of the schematic typically represents a specific function or system within the machine. Begin by locating the main components and understanding how they interact with one another. Pay attention to any labels or numbers that can help distinguish parts from one another, as these will be useful when cross-referencing with physical components.

Next, refer to any accompanying documentation or legends that provide additional context. These resources often include detailed descriptions of the components and their corresponding locations, making it easier to pinpoint specific areas in the layout. With this knowledge, you can confidently identify any part in the schematic and ensure proper maintenance or replacement when necessary.