Proper maintenance of construction equipment relies heavily on understanding the layout and functionality of its individual components. When working with heavy-duty machines, it’s essential to have a clear map of each part and its role in overall performance. This knowledge helps in troubleshooting, repairing, and enhancing the longevity of the equipment.

One of the most effective ways to maintain machinery is by referring to a detailed guide that illustrates the relationship between different mechanical elements. These guides serve as visual tools, providing a roadmap for technicians to identify, replace, or repair parts efficiently. With the right resources, identifying issues and performing necessary maintenance becomes a straightforward task.

Whether you’re dealing with routine upkeep or addressing unexpected malfunctions, having access to a comprehensive reference is key to keeping operations running smoothly. Understanding how each component works together can save time, reduce repair costs, and minimize downtime in the field.

Understanding John Deere 250 Skid Steer

Heavy machinery used in construction and agriculture requires a solid understanding of its structure to ensure efficient operation and long-term performance. These machines are designed to perform specific tasks, from lifting and carrying to digging and pushing, and they rely on various components working seamlessly together. A thorough knowledge of each element helps operators and technicians maintain the equipment properly and address issues promptly.

With these vehicles, each individual feature plays a significant role in their functionality. Below are key aspects to keep in mind:

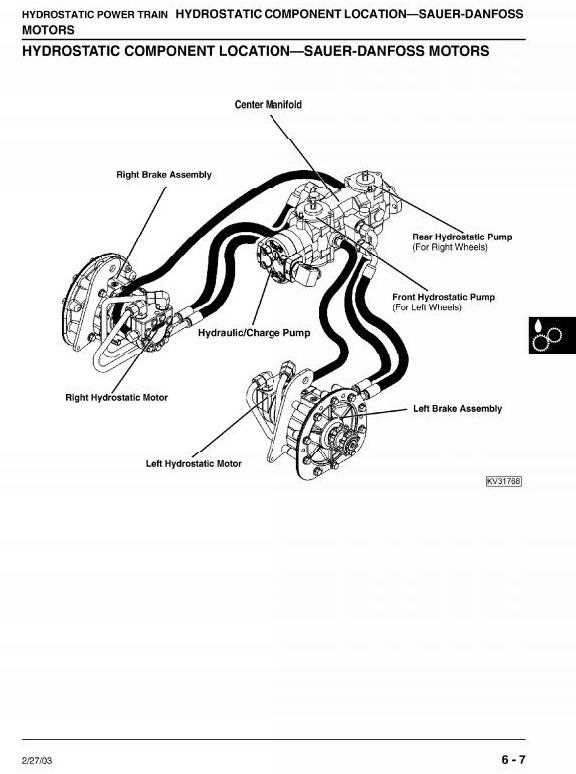

- Hydraulic System: Responsible for powering the lifting arms and other critical functions. Regular maintenance of this system ensures smooth operation.

- Engine and Transmission: These elements drive the machine and require consistent checks to maintain power efficiency and reliability.

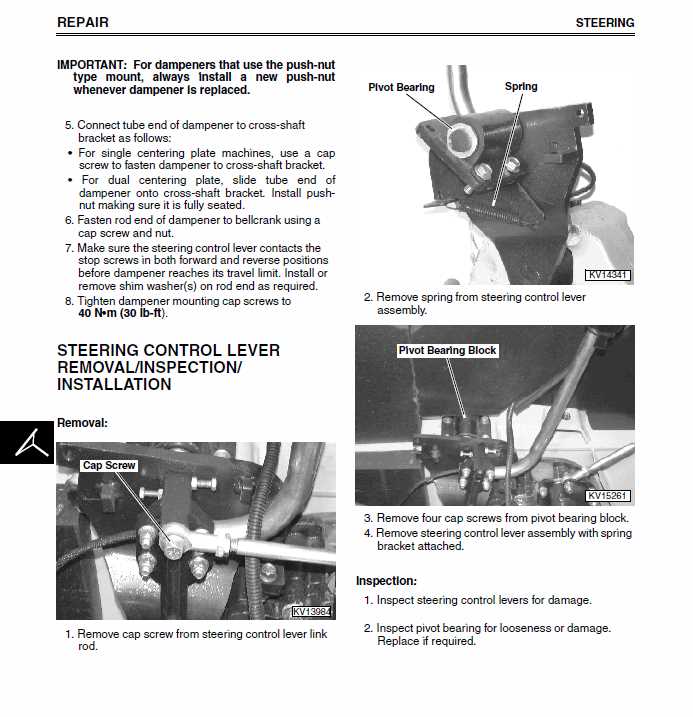

- Steering Mechanism: Unique in its design, this system allows the vehicle to navigate tight spaces with ease, making maneuverability essential for precision tasks.

- Frame and Chassis: The structural base that supports all other components, the integrity of this part is crucial for overall machine stability and safety.

Understanding the overall mechanics of these vehicles, as well as the function of each system, makes it easier to handle routine checks and identify potential issues before they become costly problems.

Key Components of the 250 Skid Steer

Understanding the main elements of a compact loader is crucial for anyone responsible for maintaining or operating such machinery. These machines are equipped with various systems that work together to ensure smooth and effective operation. By becoming familiar with each component, operators can perform necessary maintenance and troubleshoot issues more efficiently.

Among the primary components, several stand out as essential for the machine’s overall function:

- Hydraulic System: This system controls the movement of lifting arms and other attachments. Regular inspection ensures that the hydraulics are functioning optimally, preventing costly repairs.

- Powertrain: The combination of engine and transmission provides the necessary power for the machine to operate. Keeping this system in top condition ensures reliable performance in tough working environments.

- Lift Arms and Attachments: The ability to lift, carry, and place materials relies heavily on the efficiency of these arms. Understanding how to maintain them extends their operational lifespan.

- Control System: The system that enables precise movement of the vehicle and attachments. Proper calibration and adjustments are needed to guarantee smooth control during use.

- Cooling System: Ensuring that the engine does not overheat is essential. Regular checks of the radiator and coolant are necessary for optimal performance and to avoid overheating issues.

By focusing on these key components, operators can enhance their ability to manage the equipment, reducing downtime and improving overall productivity.

How to Use the Parts Diagram

Properly navigating a reference guide for equipment components can make maintenance and repairs significantly easier. These resources provide a visual representation of the machine’s various parts, helping to identify their locations and functions. Knowing how to read and utilize this guide ensures that repairs are done efficiently and accurately, saving both time and resources.

Identifying Key Components

The first step in using any reference guide is familiarizing yourself with the layout of the machine. Each part is typically numbered or labeled for easy identification. By cross-referencing these labels with the manual, you can easily determine the exact location and function of any component, making maintenance and troubleshooting more straightforward.

Repair and Replacement Tips

Once you have identified the components needing attention, the next step is understanding the repair or replacement process. The guide often includes helpful notes on disassembly, necessary tools, and installation procedures. Ensuring that you follow the instructions step by step reduces the risk of mistakes and ensures a successful repair.