When maintaining or repairing machinery, understanding the individual components and their functions is crucial. A clear visual representation can make the process much easier, allowing you to identify each element quickly. This guide provides an essential reference for anyone looking to gain a deeper understanding of a specific model’s construction and how its various parts interact.

Whether you’re performing routine maintenance or troubleshooting issues, knowing where to find the exact components you need is key. With detailed illustrations, it’s possible to pinpoint replacement items and assess wear or damage accurately. Understanding how each part fits into the overall system ensures smoother repairs and efficient upkeep, saving both time and effort.

With the right resources at hand, you’ll be able to take on repairs with confidence and precision.

Understanding John Deere 285 Components

Effective maintenance and repair start with a thorough understanding of how each individual element contributes to the overall functionality of the machine. Familiarity with the different components allows users to identify wear or malfunctions more quickly, leading to more efficient repairs and replacements. With detailed guidance, it’s easier to work through the machinery’s layout and pinpoint the necessary parts for servicing.

Each section of the system plays a unique role in ensuring smooth operation. For instance, mechanical elements like engines, transmissions, and other vital sections require particular attention during upkeep. Understanding the relationship between these components is crucial for avoiding unnecessary damage and preventing costly repairs.

By recognizing the function of every component, users can ensure long-term reliability and performance.

How to Use the Parts Diagram Effectively

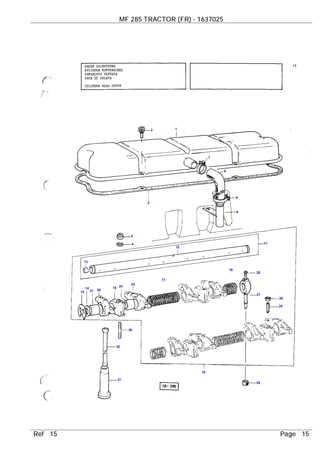

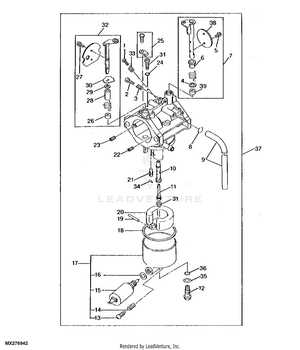

When working with complex machinery, a visual guide can be an invaluable tool for identifying components and understanding their connections. To use such a guide effectively, it’s essential to familiarize yourself with the layout and labeling system. This will allow you to quickly locate the required sections, whether for maintenance, troubleshooting, or replacement.

Begin by studying the overall structure, noting how the parts are grouped by function. This helps in pinpointing the exact location of any item you may need to work with. Pay close attention to the reference numbers or labels associated with each part, as these are crucial for ordering the correct replacements. With practice, you’ll be able to navigate through the visual representation effortlessly, making the entire repair process much smoother.

By mastering the use of these guides, you can reduce downtime and ensure accurate, efficient repairs.

Common Issues and Replacement Parts for John Deere 285

Over time, machinery may experience common issues that require attention and part replacement. Identifying these problems early can prevent further damage and costly repairs. Common issues often involve worn-out components, faulty connections, or reduced efficiency due to general wear and tear. Understanding which parts need regular inspection can save time and ensure smoother operation in the long run.

Frequent Mechanical Problems

One of the most common issues involves the engine and transmission system. These vital components may suffer from reduced power or responsiveness due to lack of maintenance or part degradation. Regular checks on filters, belts, and lubricants help to maintain proper performance. If any part appears worn or damaged, it is crucial to replace it promptly to avoid more extensive issues down the line.

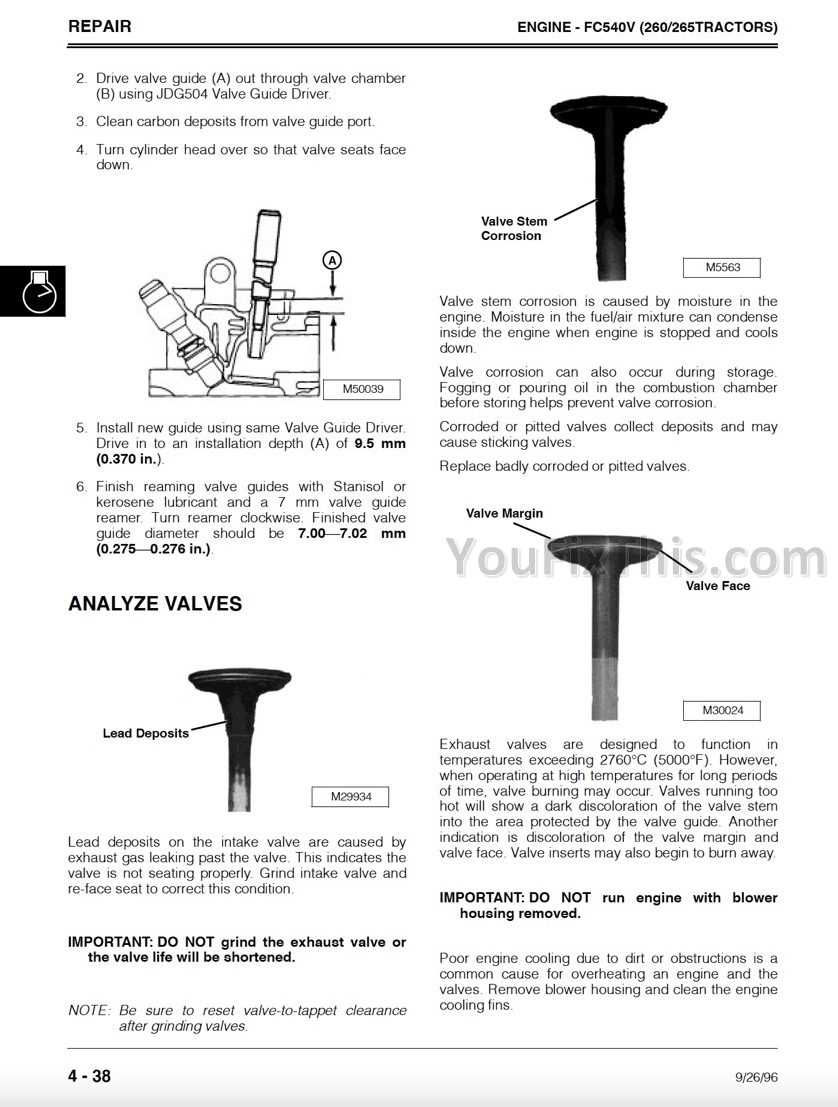

Identifying Worn Components

Another typical issue is the wear on components such as gears, seals, and valves. These parts can deteriorate over time, leading to leaks, reduced function, and potential breakdowns. Using a visual guide or detailed schematic helps identify the specific components that need replacing. It’s important to always use high-quality replacements to maintain overall efficiency and safety.

Addressing these issues in a timely manner with the correct parts ensures the equipment operates at peak performance.