Proper maintenance and repair of any machine require a clear understanding of its individual components and their functions. A detailed visual representation of the machine’s layout can greatly assist in identifying parts that need attention. Whether you’re a professional mechanic or an enthusiastic DIYer, having access to a comprehensive guide is crucial for efficient work.

By studying an organized map of a tractor’s essential elements, users can quickly locate the necessary components, making repairs and replacements much more manageable. This knowledge not only speeds up the process but also ensures that the machine runs smoothly for longer periods, reducing the risk of costly breakdowns.

In this article, we’ll guide you through how to interpret such a map, highlighting the most common components, their functions, and offering practical advice for performing basic maintenance tasks. This resource is designed to help both beginners and experienced users gain a deeper understanding of their machine’s mechanics.

Understanding the Tractor’s Components

When working with any complex machine, it’s essential to gain a thorough understanding of its various elements. Each individual component plays a critical role in the overall performance of the machine. Recognizing how these parts interact and function together is vital for ensuring optimal operation and for performing maintenance tasks efficiently.

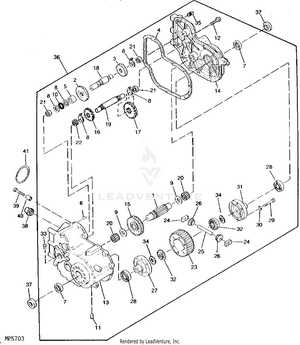

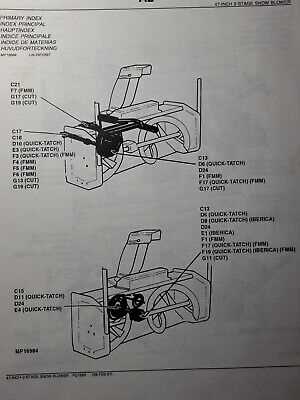

Having a clear visual map of the machine’s structure can significantly aid in identifying parts that require attention. Knowing where specific components are located and how they connect to other elements helps users troubleshoot issues, replace worn-out components, or perform upgrades with ease.

Key Components to Focus On

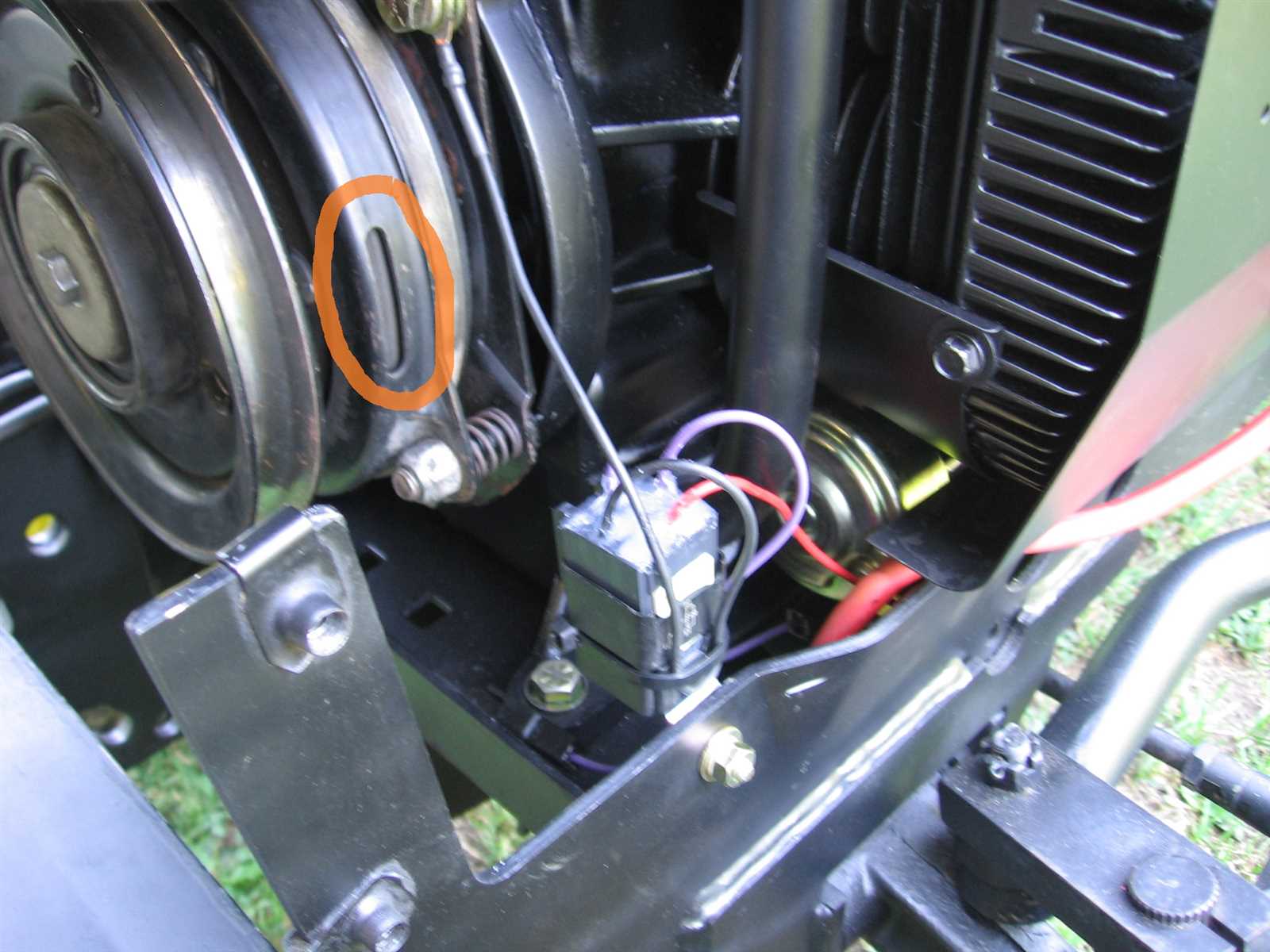

Among the critical areas to focus on are the engine assembly, transmission, and drive system. These sections often require the most frequent maintenance due to the amount of stress they endure during operation. Understanding the layout of each part can help you quickly identify any damage or wear and tear that might need attention.

Practical Applications for Maintenance

Once you understand the layout and function of key components, performing routine tasks such as oil changes, filter replacements, and belt inspections becomes more straightforward. Regular checks of these vital sections ensure that the machine remains functional and reliable, reducing the risk of breakdowns and extending its lifespan.

How to Read the Tractor’s Layout

Understanding how to interpret a machine’s visual layout is a key skill for anyone looking to maintain or repair it. These layouts provide a clear, organized representation of the components and their connections, making it easier to locate specific parts and understand their function. By knowing how to read these diagrams, users can quickly identify areas that require attention, saving time and improving efficiency.

Typically, these illustrations use standardized symbols and labels to represent various parts. The key to reading them effectively is becoming familiar with the terminology and recognizing how different components are linked. Once you understand the conventions used, the process of identifying and addressing problems becomes much simpler.

Start by focusing on the general layout. Larger sections like the engine, drive system, and transmission are often highlighted or labeled clearly. Then, break down the individual components within each section to locate any damaged or worn parts. This approach will help you systematically check the entire machine and ensure nothing is overlooked.

Common Repairs Using the Layout

Knowing how to effectively use a machine’s visual layout can help simplify common repairs and maintenance tasks. By referring to these diagrams, users can quickly pinpoint which parts need replacement or attention. This can save both time and effort during routine check-ups or emergency fixes.

Here are some of the most common repairs that can be made by understanding the layout:

Engine and Transmission Maintenance

The engine and transmission are vital sections that often require attention. Key tasks include:

- Replacing the air filter to improve engine efficiency.

- Changing spark plugs for better ignition performance.

- Inspecting and replacing the transmission belt to ensure smooth operation.

Drive System and Electrical Repairs

The drive system and electrical components are also common areas that may need repairs. Common issues to address include:

- Inspecting and replacing worn-out tires or wheels.

- Reconnecting or replacing damaged wiring in the electrical system.

- Lubricating moving parts to prevent friction and damage.

By regularly checking these sections and understanding the layout, you can perform repairs quickly and effectively, ensuring the machine remains in top working condition.