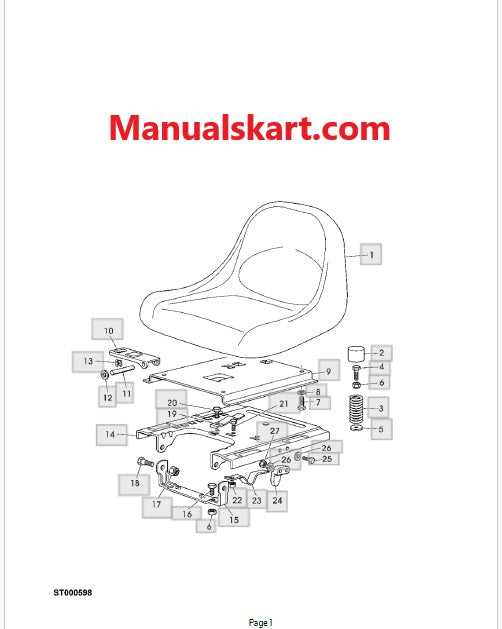

Proper maintenance of any equipment requires a clear understanding of its internal structure. Identifying and knowing the function of each element is crucial for both repairs and replacements. This guide provides a comprehensive view of how different sections of the machine work together to ensure smooth performance.

Visual representation plays an essential role in simplifying the identification process. By studying a clear chart of the machine’s configuration, users can quickly pinpoint specific components that need attention. These visual aids allow for a more organized approach to maintenance and reduce potential errors during the repair process.

With the correct knowledge, anyone can efficiently perform troubleshooting and make necessary fixes. Having access to an accurate schematic is the first step toward ensuring your equipment stays in top condition for longer, minimizing downtime and costly repairs.

Understanding the Machine Configuration

Grasping the structure of any mechanical system is essential for efficient maintenance. The visual representation of a machine’s components allows users to see how each part interacts with others, aiding in troubleshooting, repairs, and upgrades. A clear layout helps to quickly identify potential issues and understand the overall mechanics of the system.

Why Visual Guides Matter

Having access to an accurate schematic makes it easier to pinpoint components that require attention. Whether you are dealing with wear and tear or a malfunction, these detailed illustrations show the exact locations and connections of each piece. This visual aid minimizes the guesswork and ensures precision in maintenance tasks.

Using the Guide for Efficient Repairs

By using a comprehensive guide, users can approach repairs systematically. Identifying the right part or system becomes more straightforward, preventing mistakes and improving the repair process. With the right knowledge and a visual reference, even complex maintenance tasks become manageable, ensuring the longevity of the machine.

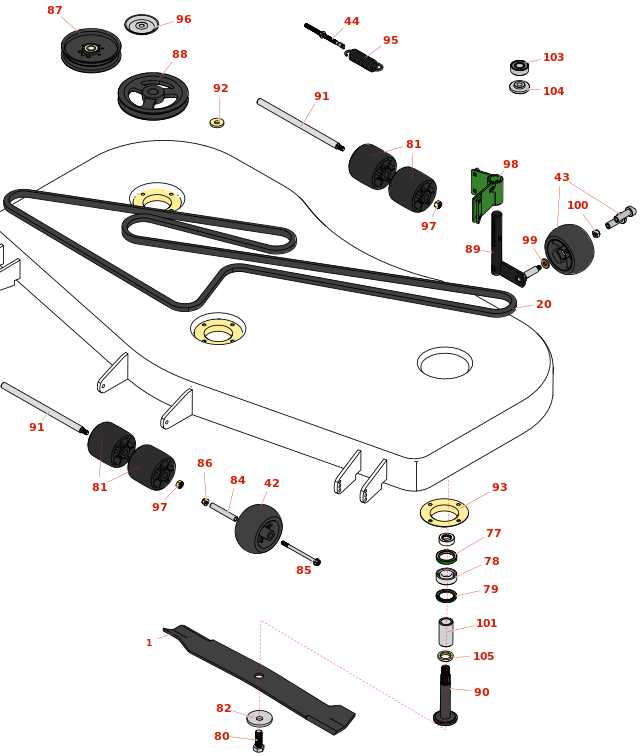

Key Components of the Machine

Every machine consists of essential elements that work together to ensure smooth operation. These primary components are the heart of the system, responsible for its functionality, power, and efficiency. Understanding each part’s role is vital for effective troubleshooting and maintenance.

Key elements include the engine, transmission, control systems, and various mechanical parts that facilitate movement and performance. Each of these elements must be properly maintained to ensure optimal operation. By familiarizing yourself with these components, you can identify areas that may require attention or upgrades, ultimately extending the life of the equipment.

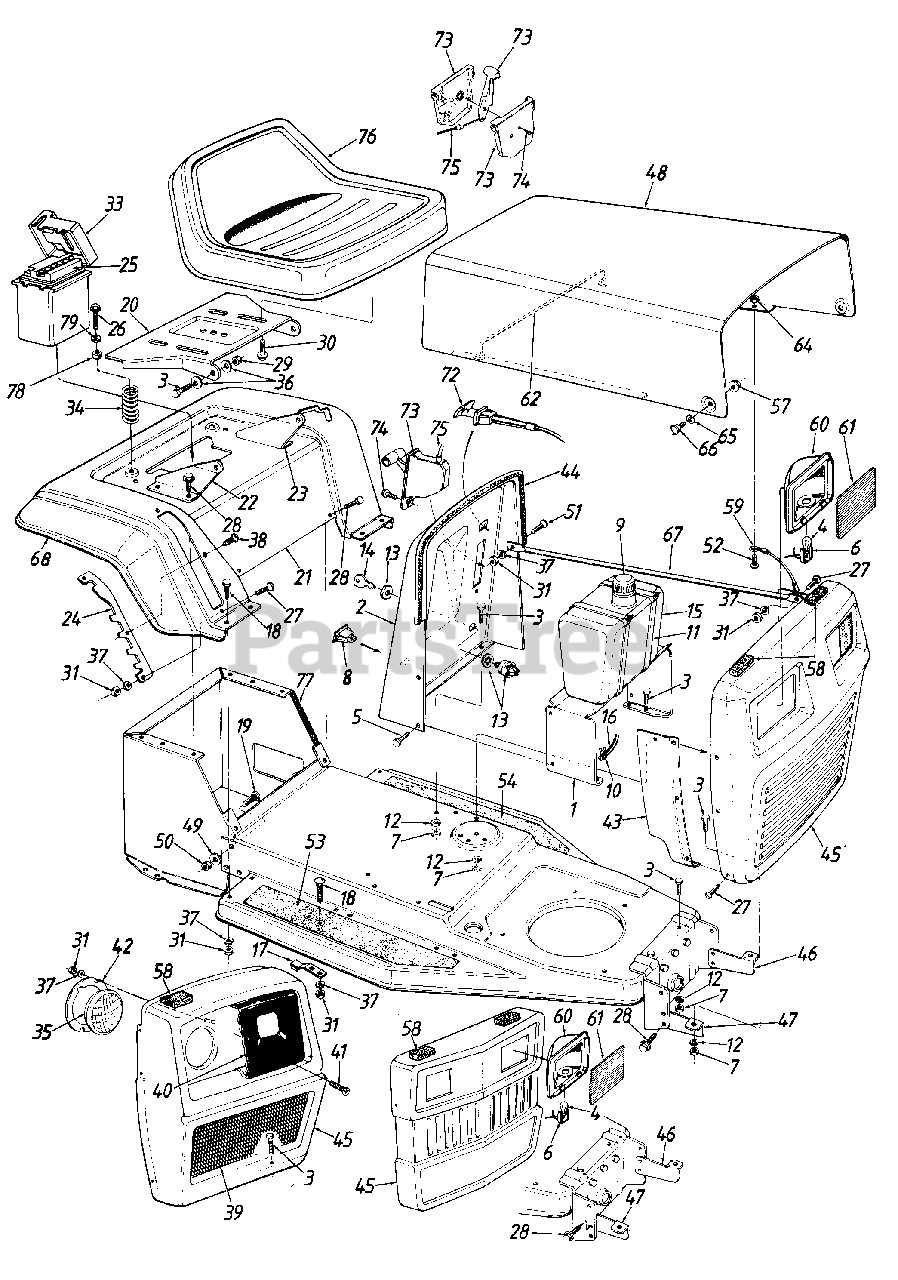

How to Use the Visual Guide Effectively

Utilizing a visual schematic properly can greatly improve the efficiency of maintenance and repair tasks. By understanding the layout and function of each component, you can quickly identify what needs attention. The key to using this tool effectively is knowing how to interpret the information presented and applying it to real-world situations.

Step-by-Step Interpretation

Start by identifying the main sections of the schematic. These sections usually represent larger systems within the machine. From there, follow the connections and lines to understand how smaller components interact. This methodical approach ensures that no part is overlooked, and you can pinpoint exactly where a problem may lie.

Practical Application for Repairs

Once you’ve identified the necessary components, use the schematic to guide your repair process. This can help you avoid unnecessary disassembly and ensure you replace the right parts. It also allows you to verify the correct placement and connections of the components to ensure proper functionality after repairs are completed.