Understanding the intricate components of farming machinery is crucial for maintaining peak performance. A well-maintained machine ensures efficiency and reduces downtime, contributing to productivity on the field. Regular inspection and knowledge of each part’s function are key to smooth operations.

Detailed breakdowns of each element help users identify issues early, preventing costly repairs. This guide will provide you with the essential steps to navigate the mechanical systems of your equipment with ease.

Proper care and attention to all the machinery’s elements will extend its lifespan and guarantee optimal functioning during high-demand tasks. The importance of knowing the layout and specifics of every part cannot be overstated for anyone involved in agricultural operations.

Understanding the Farming Equipment

Efficient harvesting and processing of crops rely heavily on reliable machinery. These machines are designed to handle various tasks, from gathering materials to compacting and binding them for transport. Understanding how each component functions ensures smooth operation and reduces the risk of mechanical failures during critical periods.

Key Features and Functions

Modern machines for harvesting are equipped with advanced systems that work together to achieve specific tasks. The core mechanism consists of moving parts, sensors, and hydraulic systems that work in harmony to collect, compress, and package materials. Each system plays a vital role in ensuring the overall performance and efficiency of the equipment.

Maintenance and Troubleshooting

Regular maintenance of the machinery is essential to prevent breakdowns. Knowing the location and purpose of each component allows operators to quickly identify potential issues and perform routine checks. This knowledge helps in avoiding costly repairs and ensures that the equipment is always ready to perform under demanding conditions.

Key Components of the Harvesting Machine

Each farming machine is made up of several critical elements that work together to complete the task efficiently. Understanding how these systems interact is essential for maintaining performance and preventing issues. From the intake mechanism to the compression system, each part plays a unique role in the overall function of the machine.

Compression and Binding Mechanism

The main function of any agricultural machine is to gather and bind material into manageable units. This system includes moving components that grab, compact, and secure the material into tight bundles. Hydraulic systems and conveyor belts are often used to ensure smooth operation and uniformity in the finished product.

Drive and Power Systems

The drive system, powered by an engine or motor, provides the necessary force for the machine to operate. It is connected to various mechanical parts that drive the compression system, gathering mechanisms, and moving belts. Regular checks of the drive components, including the engine and hydraulic pumps, are necessary for ensuring continuous performance.

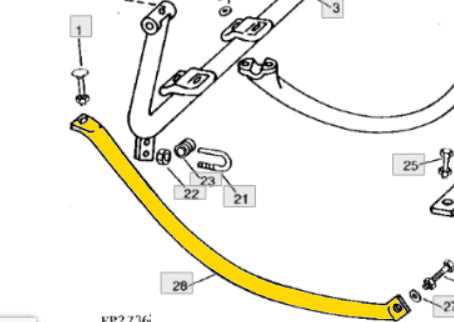

How to Read the Equipment Schematic

Interpreting the schematic of any machine is an essential skill for anyone involved in maintenance and repair. These visual representations provide detailed insights into the components, connections, and layout of the machinery. A clear understanding of how to read these schematics enables operators and technicians to identify issues and make informed decisions about repairs and upgrades.

When looking at a schematic, the key is to identify the various components and understand their functions within the system. Here are some important steps to follow:

- Identify key components: Start by locating the primary systems of the machine, such as the engine, compression unit, and hydraulic mechanisms.

- Understand the symbols: Each part in the diagram is represented by specific symbols. Familiarize yourself with these symbols to quickly identify different components.

- Follow the connections: The schematic will show how the various parts are connected. Pay attention to the flow of power, fluid, or motion between components.

By carefully studying the schematic, you can gain a better understanding of how the machine operates and spot potential areas for improvement or repair.

Identifying Common Maintenance Issues

Proper maintenance is key to extending the lifespan of any farming machine, but even with regular care, certain issues are more likely to occur. Recognizing these common problems early can prevent more severe damage and ensure the equipment continues to perform at its best. By understanding the most frequent maintenance issues, operators can take proactive measures to address them promptly.

One of the most common issues faced by machinery is wear and tear on moving parts. Regular inspection of components such as belts, gears, and hydraulic systems is crucial, as these parts can become damaged over time due to constant use. Other frequent issues include clogged systems, which can affect the flow of materials and reduce efficiency. Additionally, failure to maintain the engine or power system may result in loss of power or functionality, requiring immediate attention.