When working with complex machinery, having a clear view of its individual components is essential. A detailed schematic can help identify each part, making maintenance, repairs, and replacements more efficient. By using these visual guides, operators and mechanics can ensure their equipment runs smoothly and effectively.

These schematics serve as valuable tools for understanding the layout and functionality of each part. Whether it’s for troubleshooting, replacing worn-out components, or performing regular upkeep, a well-constructed guide allows you to locate the exact area that requires attention. This simplifies the entire process and reduces unnecessary downtime.

Utilizing the right diagrams is an essential step in keeping your machinery in top condition. Knowing where to look for specific parts or how components interact helps prevent costly mistakes and ensures safety during operation. These visual references provide clarity and support for any maintenance tasks, whether simple or complex.

Understanding the John Deere 400 Diagram

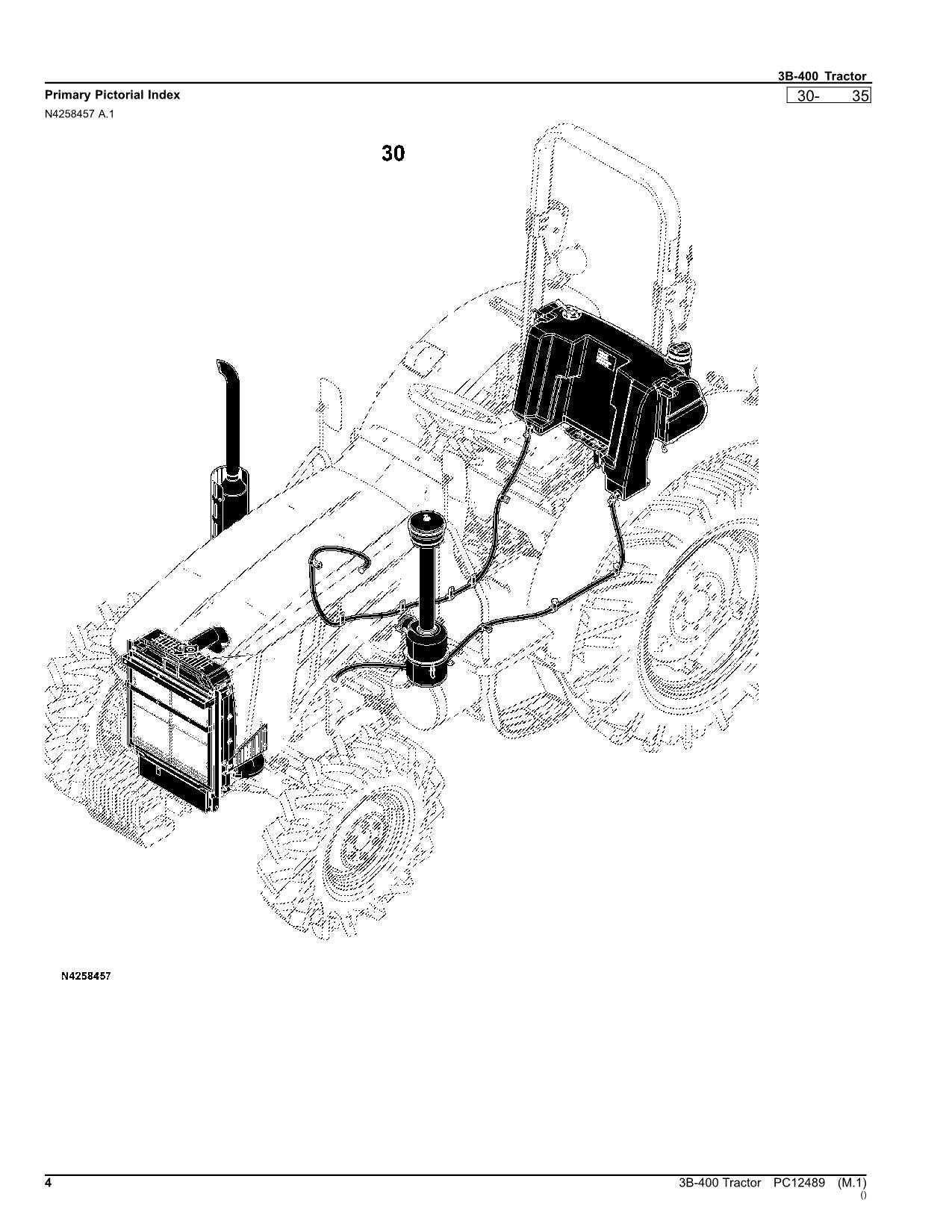

Understanding the layout of equipment components is crucial for efficient maintenance and repair. A comprehensive schematic provides a visual map of how different sections and elements are interconnected, allowing for a clearer approach to troubleshooting and upkeep. Each part’s role within the overall system becomes apparent, enabling better decision-making when addressing issues.

The layout includes detailed illustrations of all major components, showing their placement and relationship to one another. This makes it easier to identify where potential problems may arise and which areas require immediate attention. By studying these visual aids, operators can gain a deeper understanding of how their machinery functions and how to keep it in optimal condition.

These guides are designed to streamline the repair process, reducing the need for trial and error. With precise references, users can confidently replace, repair, or maintain specific parts without unnecessary delays or complications. The accuracy and clarity of these schematics contribute to smoother workflows and enhanced productivity in the long run.

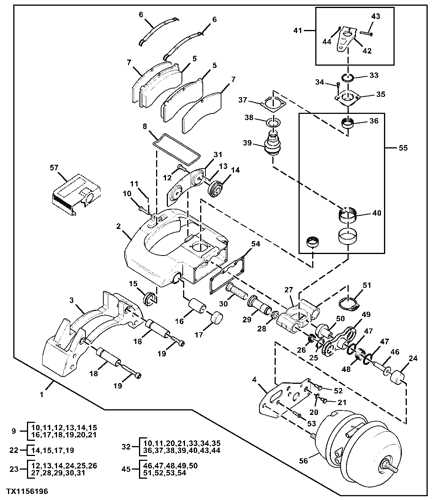

Identifying Key Parts in the Diagram

Accurately recognizing individual components in a schematic is vital for effective machinery maintenance. A well-constructed guide highlights essential sections, making it easier to locate specific areas in need of attention. Understanding the significance of each part and its placement within the larger system allows operators to make informed decisions and take appropriate actions.

Key elements are typically labeled with clear identifiers, such as part numbers and descriptions. This ensures that users can quickly match the visual representation with real-world components. It also helps avoid confusion when selecting replacements or making adjustments to specific sections of the equipment.

By focusing on the most important components, operators can streamline their repair and maintenance processes. Knowing where to focus attention minimizes time spent troubleshooting and improves overall efficiency. These insights help maximize the lifespan and performance of the machinery, ensuring it remains in peak working condition for as long as possible.

How to Use the Diagram for Maintenance

Using a schematic for maintenance involves more than just viewing a list of components; it requires an understanding of how to navigate the guide effectively. By referencing the visual layout, operators can pinpoint the exact areas that need service and identify which parts require replacement or adjustment. This step-by-step approach ensures that each task is performed with accuracy and efficiency.

When performing maintenance, start by locating the area of concern on the schematic. Cross-reference the visual with actual parts to ensure that the correct component is being worked on. This reduces errors and helps avoid unnecessary disassembly of other sections. Whether performing routine upkeep or addressing a specific issue, using the schematic as a reference point ensures a systematic approach to every task.

Additionally, these visual aids provide valuable insights into the connection between different components. Understanding how various parts interact with each other is key to diagnosing and solving problems effectively. By following the schematic, users can make informed decisions, reducing downtime and improving overall operational performance.