Maintaining and repairing agricultural machinery requires a deep understanding of its intricate components. Every machine is made up of various elements that work together to ensure its proper function. When any part begins to show wear or malfunction, knowing the exact specifications and location of each piece becomes essential for effective maintenance and repair.

In this section, we will explore how to read and interpret component schematics, providing you with the knowledge to identify the right parts for your equipment. By using detailed visuals, operators and mechanics can pinpoint potential issues and make informed decisions about repairs or replacements.

Understanding these visual tools enables both new and experienced individuals to work more efficiently and save time. With the right information, tasks become more straightforward, and the chances of improper repairs decrease significantly.

Understanding Tractor Components

For any tractor, comprehending the various mechanical systems and their functions is essential for efficient operation and maintenance. Each vehicle consists of numerous interconnected elements that ensure smooth performance. Recognizing how these components interact allows for timely repairs and helps avoid costly damage in the future. Having a solid grasp of the equipment’s structure also ensures that users can make accurate decisions when it comes to servicing or replacing specific sections.

Key Mechanical Systems

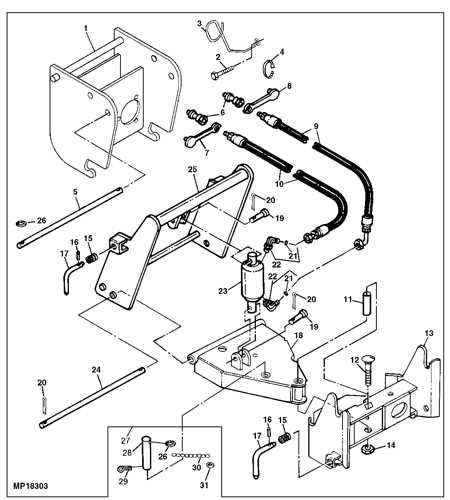

Tractors feature several core systems that drive their functionality. These systems include the engine, transmission, hydraulics, and electrical units. Each of these sections plays a crucial role in enabling the tractor to carry out its various tasks, from plowing fields to hauling loads. Familiarity with the layout and specifics of these systems is vital for diagnosing issues quickly and minimizing downtime.

Components for Effective Operation

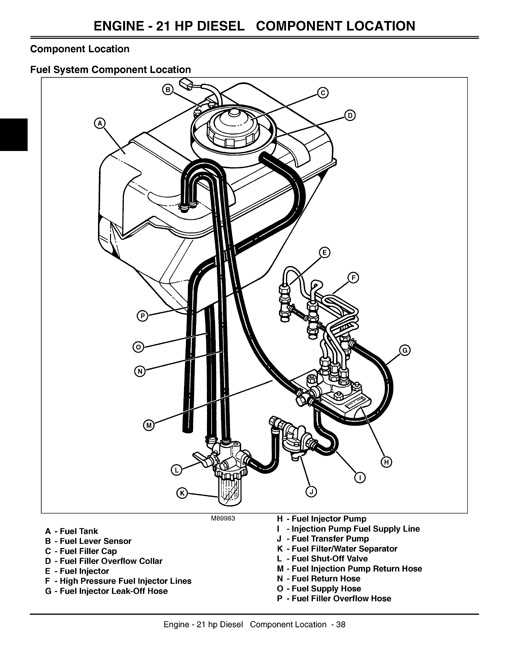

Proper operation depends on each component functioning in harmony. Key components like the steering mechanism, fuel system, and wheels must be in top condition for the tractor to perform its duties. Regular inspection and understanding of the different parts allow operators to identify wear and tear early, leading to more efficient use and longer lifespan of the equipment.

Detailed Overview of Tractor Components

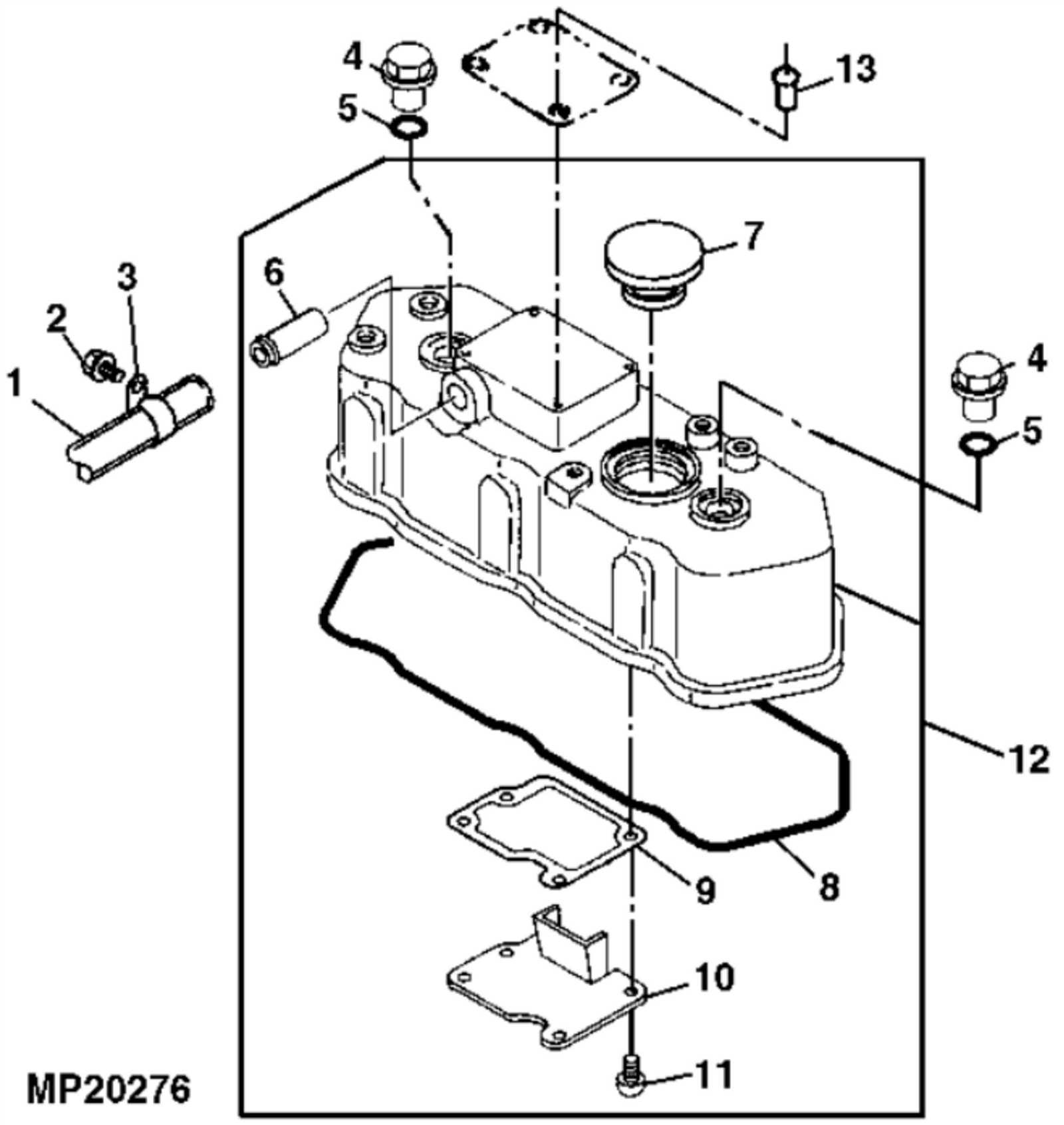

Understanding the key elements of a tractor is crucial for ensuring its performance and longevity. Each component serves a specific function that contributes to the machine’s overall efficiency. Knowing the specifics of these components helps in making informed decisions about maintenance, repairs, or upgrades. This section provides a closer look at the essential systems and individual parts that make up a modern agricultural vehicle.

Major Systems and Their Functions

Tractors are equipped with various systems that work together to perform different tasks. Below are some of the major systems that play a critical role:

- Engine: Powers the vehicle and ensures it has the necessary energy to carry out tasks.

- Transmission: Transfers the engine’s power to the wheels and allows for different speed settings.

- Hydraulic system: Enables the operation of implements and lifts heavy loads with ease.

- Fuel system: Delivers fuel to the engine for combustion and energy production.

- Electrical system: Powers essential electrical components, including lights, sensors, and control panels.

Common Components to Inspect Regularly

To maintain a tractor in peak condition, regular inspection of the following individual components is necessary:

- Air Filter: Prevents dirt and debris from entering the engine, ensuring smooth operation.

- Oil Filter: Keeps contaminants out of the engine oil, prolonging engine life.

- Battery: Powers the electrical system and starts the engine.

- Fuel Injectors: Deliver fuel to the engine in precise amounts for optimal combustion.

- Belts and Hoses: Drive various systems and should be checked for wear and tear.

How to Use the Schematic Effectively

Understanding how to read and utilize a schematic is essential for any repair or maintenance work. These visual representations break down a machine into its individual components, showing how each part fits together. When used properly, they can save time and reduce errors by helping to pinpoint issues quickly and accurately. Knowing where to look and how to interpret these schematics is key for successful troubleshooting and part replacement.

Start by familiarizing yourself with the layout of the schematic. Pay attention to the key sections that are labeled and the different symbols representing various components. Once you have an understanding of the general structure, you can focus on specific areas where issues are suspected. It is important to cross-reference the visual guide with the actual machine to ensure you are looking at the correct part and its position.

When using the schematic, always ensure that you are working with the correct version. Sometimes, minor revisions or updates can make a significant difference, so using the most current version ensures accuracy in your work. Additionally, when replacing components, follow the schematic’s detailed steps to avoid mistakes and ensure a proper fit.