When working with large machinery, understanding the individual elements that make up the system is crucial for efficient operation and maintenance. A thorough grasp of how each component interacts ensures smoother performance and reduces the risk of damage or malfunction.

Recognizing the role of each unit allows operators to identify issues quickly, making troubleshooting easier. Knowing how the key sections function together promotes better long-term care and efficient repairs. Whether for routine checkups or more intensive fixes, this knowledge is essential for maintaining optimal performance.

In this section, we will break down the essential units, providing insights into their functions, maintenance tips, and how they work within the larger framework. This guide aims to empower users with the knowledge needed for better operation and care of their equipment.

Understanding Key Equipment Components

Proper knowledge of the components that form large-scale machinery is fundamental to efficient operation and maintenance. Each unit plays a specific role in ensuring that the system functions smoothly, with minimal downtime and maximum productivity. Recognizing the purpose and functionality of each piece is vital for operators to maintain control and manage troubleshooting effectively.

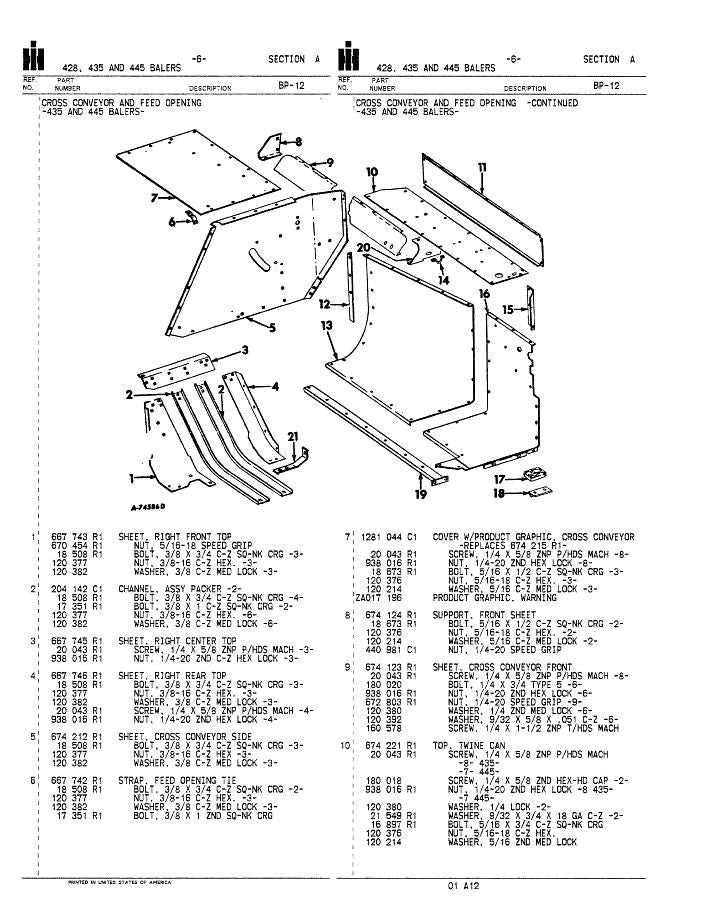

Core Units and Their Functions

Essential units within the machine serve specific functions, such as feeding materials, controlling tension, or managing power distribution. Understanding how these core sections operate together ensures that the machinery performs as intended. Regular inspection of these units can prevent wear and tear, avoiding costly repairs.

Maintenance Tips for Optimal Performance

Maintaining these components requires attention to detail. Proper lubrication, alignment checks, and timely replacements of worn-out parts contribute to longevity. By following maintenance guidelines specific to each unit, operators can maximize performance and ensure that the equipment stays in good working condition over time.

Key Parts and Their Functions Explained

Understanding the various components of large equipment is essential for proper operation and upkeep. Each section of the machine plays a vital role in the overall system, contributing to its efficiency and reliability. By learning the functions of these critical units, operators can ensure better performance and avoid unnecessary issues during use.

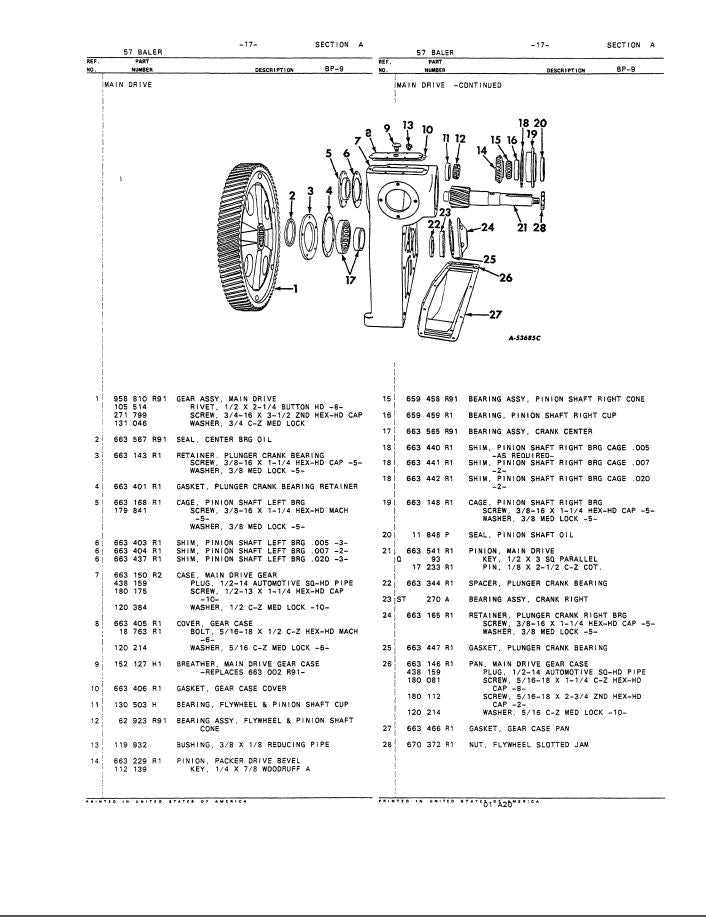

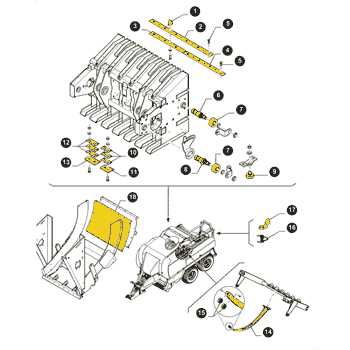

Feeding and Power Transmission Units

The feeding mechanism and power transmission units are responsible for moving materials through the system and ensuring that energy is distributed effectively. These components must be well-maintained to avoid disruptions, as any malfunction here can lead to delays and reduced productivity. Regular checks on tension, alignment, and wear can help prevent breakdowns.

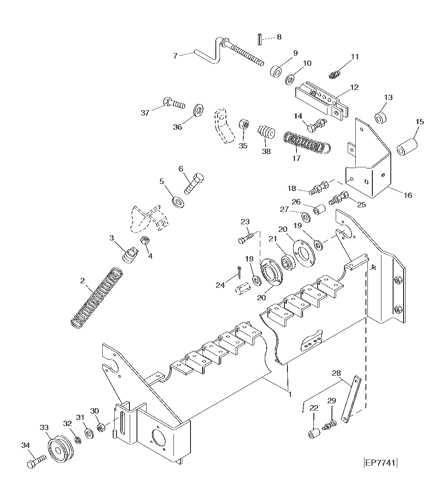

Compression and Ejection Systems

Once materials are processed, compression and ejection systems work together to form and release the final product. These units require proper calibration to ensure uniformity and optimal performance. Keeping them in good condition through routine maintenance will help avoid excessive wear and potential failure.

Step-by-Step Guide to Baler Maintenance

Regular maintenance of machinery is essential for ensuring smooth operation and preventing unexpected failures. By following a structured approach, operators can maintain their equipment in optimal condition, prolonging its lifespan and reducing costly repairs. This guide outlines the key steps involved in keeping the machine in peak performance.

Begin by performing a thorough inspection of all critical components, including feeding systems, power transmission units, and compression mechanisms. Check for any signs of wear or damage and address any issues promptly. Lubrication of moving parts is crucial to minimize friction and maintain efficiency.

Next, ensure that the machine is properly calibrated to prevent uneven performance. Regularly monitor the alignment of key units, making adjustments as necessary. Clean all filters and cooling systems to avoid debris buildup, which can hinder performance and lead to overheating.

Finally, replace worn-out or damaged components before they cause more significant issues. Keeping a log of maintenance tasks will help track the machine’s condition over time, allowing for more informed decisions about repairs and replacements.