When it comes to maintaining outdoor machinery, having a clear understanding of its individual parts is essential for smooth operation and longevity. A well-organized guide to these components can make repair tasks easier and more efficient. Whether you are looking to replace a damaged piece or just want to familiarize yourself with the machine, a thorough breakdown of its elements is crucial.

In this section, we will explore how to identify, troubleshoot, and replace various components of your equipment. Knowing the functions and locations of each part will help you save time and avoid unnecessary repairs. Additionally, a good grasp of the overall structure allows for a more precise and effective approach to maintenance.

Proper identification and understanding of each part contribute significantly to the efficiency of your machine. A well-maintained system reduces wear and tear, improving both performance and safety. By following a clear guide, you can confidently handle any necessary adjustments or fixes yourself.

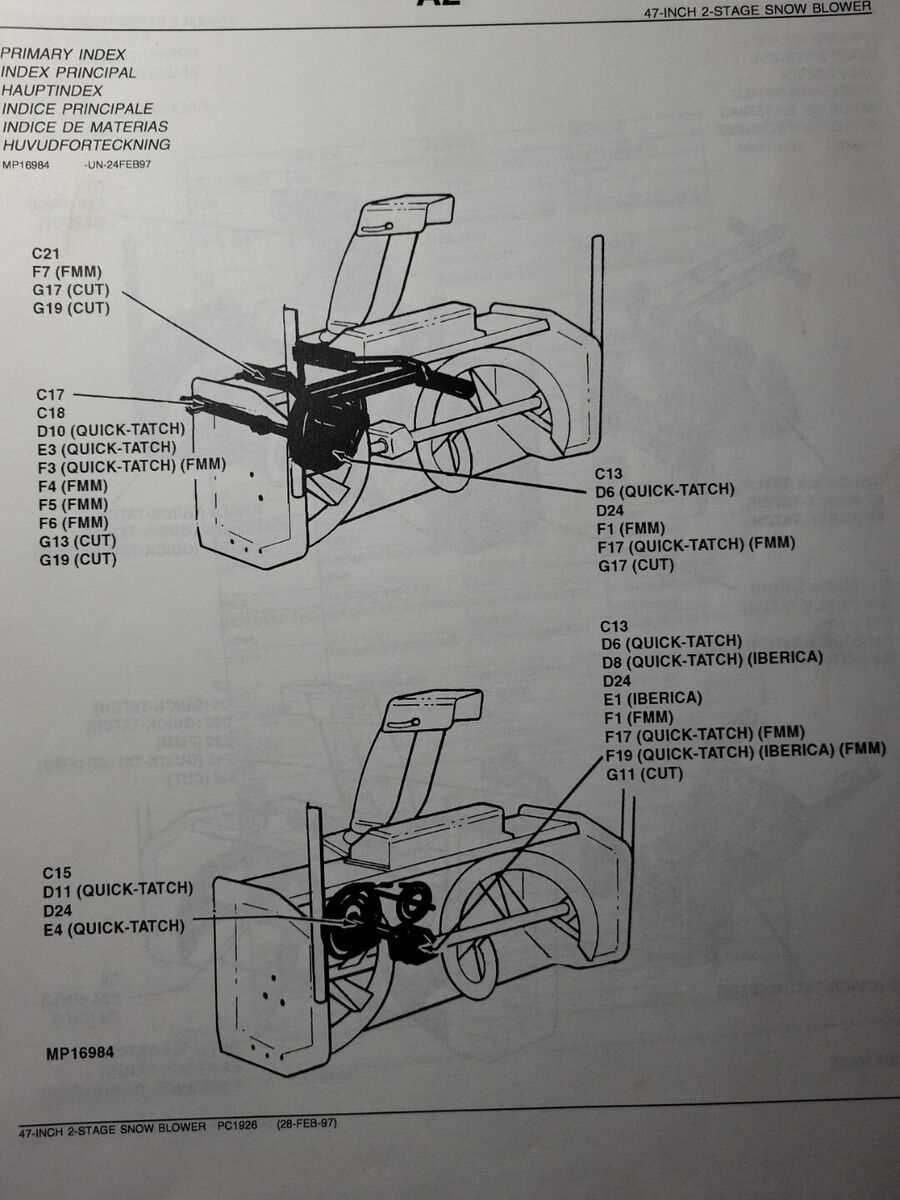

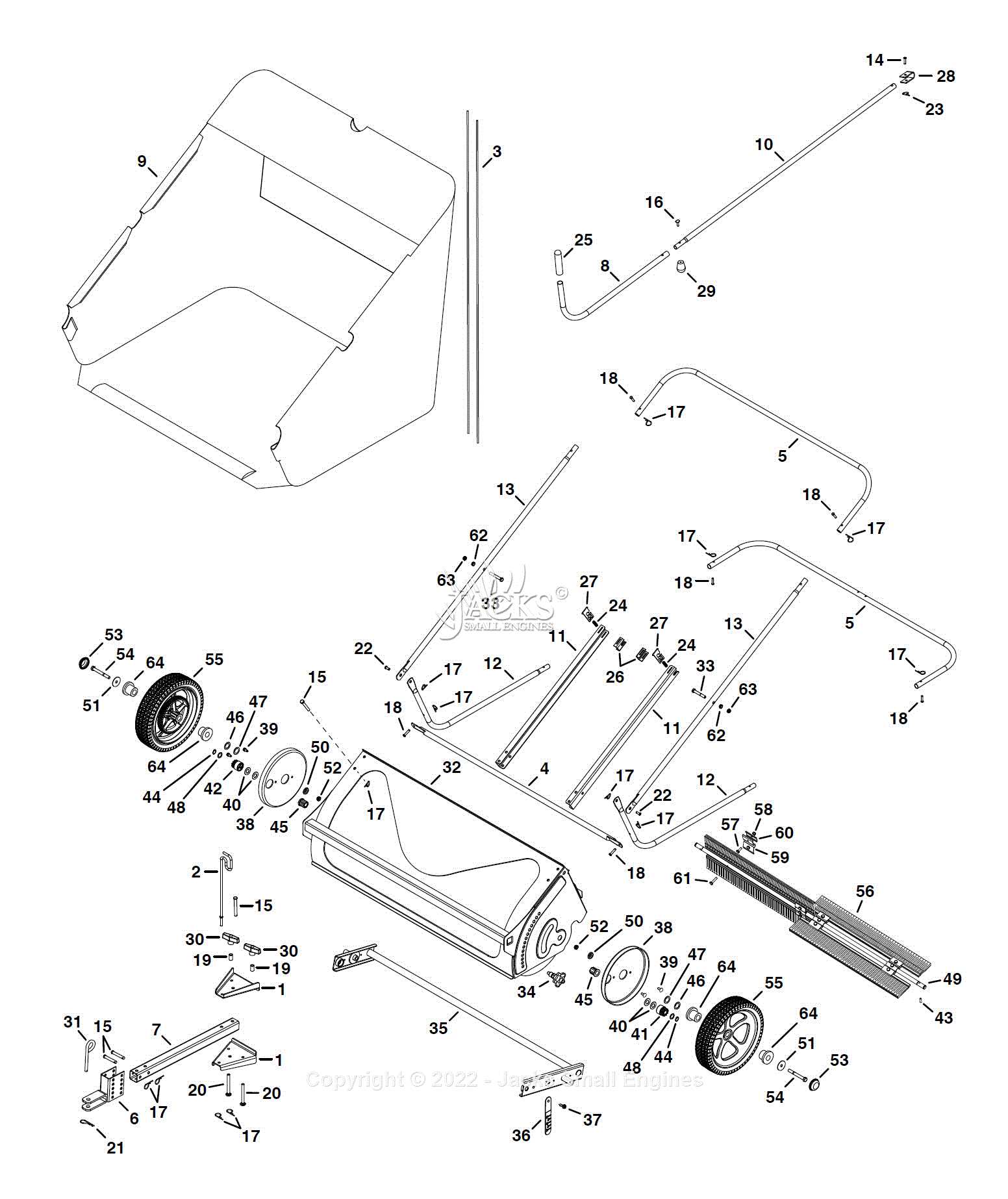

John Deere 44 Snowblower Part Breakdown

Understanding the individual components of your machine is key to maintaining its functionality. Each element plays a vital role in ensuring smooth operation during use, whether it’s for clearing paths or tackling larger areas. By breaking down the system, you’ll gain insight into its design, making troubleshooting and repairs much easier.

The main sections of your equipment can be categorized into mechanical and electrical components. Mechanical elements, such as the engine, auger, and chute, interact to facilitate movement and snow clearing. Electrical parts handle powering up and controlling the system, ensuring efficiency and proper functioning. Identifying each of these sections allows for a targeted approach when servicing or replacing damaged pieces.

Understanding the placement and function of each component is essential for performing repairs or upgrades. For example, components like the auger drive and gear mechanisms require regular inspection to prevent malfunctioning. Familiarizing yourself with these parts enables you to keep the machine in optimal condition throughout the winter season.

Identifying Key Components for Repairs

When it comes to maintaining your equipment, knowing which parts are most susceptible to wear and tear is essential. Proper identification of these critical elements will help you quickly address any issues that arise. With the right knowledge, you can pinpoint problems early and take preventive measures before they affect the overall performance.

Mechanical Elements

The mechanical system is the heart of your machine, and several components within this section need regular inspection. Key parts like the drive belt, auger, and friction wheel play a significant role in performance. Understanding their functions and recognizing any signs of wear will allow you to act before any damage occurs.

Electrical and Control Systems

Electrical components and control systems are just as crucial. Issues with wiring, switches, or fuses can lead to operational failure, especially if neglected. Identifying and maintaining these parts ensures your equipment operates smoothly when you need it the most. Regularly checking the battery, control panel, and electrical connections can prevent unexpected malfunctions.

How to Use the Parts Diagram Effectively

Using a visual guide to understand the layout and connection of various components can significantly streamline the repair and maintenance process. A well-structured reference helps you identify each part and its placement, making it easier to troubleshoot and replace damaged elements without confusion.

To use this guide effectively, start by familiarizing yourself with the overall layout. Focus on each section and ensure you understand how the components interact with one another. This knowledge will enable you to identify the exact part you need and its corresponding position within the machine. Having a clear understanding of this structure reduces the chances of mistakes when ordering or replacing components.

Once you’ve pinpointed the necessary components, refer back to the visual for assembly or disassembly instructions. Being able to match the labeled parts with their locations makes the repair process much smoother and quicker. A proper understanding ensures that each part is correctly positioned, helping the system function optimally after repairs.