Understanding the internal mechanisms of farm machinery is essential for maintaining performance and preventing costly repairs. Recognizing each part’s function and how they interact can simplify troubleshooting and boost efficiency. With the right knowledge, you can extend the lifespan of your equipment and ensure its reliability for years to come.

In this guide, we will break down the critical elements that make up these agricultural machines, providing you with a clear overview of their structure. Whether you’re a seasoned operator or new to machine maintenance, this information will help you quickly identify and address potential issues.

Exploring the system behind the complex components will also help you gain a deeper understanding of how everything works together. Knowing where each part fits into the whole can drastically improve your approach to repair and upkeep, allowing for more effective maintenance practices.

Understanding the Key Components of Farm Machinery

To efficiently operate and maintain any agricultural machine, it is crucial to understand the individual components and their roles. Each element plays a specific part in ensuring the equipment performs optimally, from feeding the material to creating a finished product. A deeper understanding of these elements will help you perform repairs and maintenance more effectively, preventing malfunctions and enhancing machine longevity.

Key components in these machines can be grouped into several categories, each responsible for a particular function. By recognizing how they work together, you can identify potential issues early and address them before they affect the machine’s performance.

- Feeding System: Responsible for drawing in materials and preparing them for further processing.

- Compression Mechanism: Compresses the gathered materials into compact units.

- Drive System: Powers the various mechanical parts of the equipment to keep it moving smoothly.

- Hydraulic Components: Aid in the movement and operation of key parts, ensuring smooth functionality.

- Control System: Allows the operator to manage settings and adjust machine operations efficiently.

By familiarizing yourself with these primary groups, you can better troubleshoot issues, identify wear and tear, and maintain the equipment to ensure it works as efficiently as possible. A clear understanding of the machinery’s internal workings also enables more effective planning for routine maintenance and repairs, minimizing downtime during the busy season.

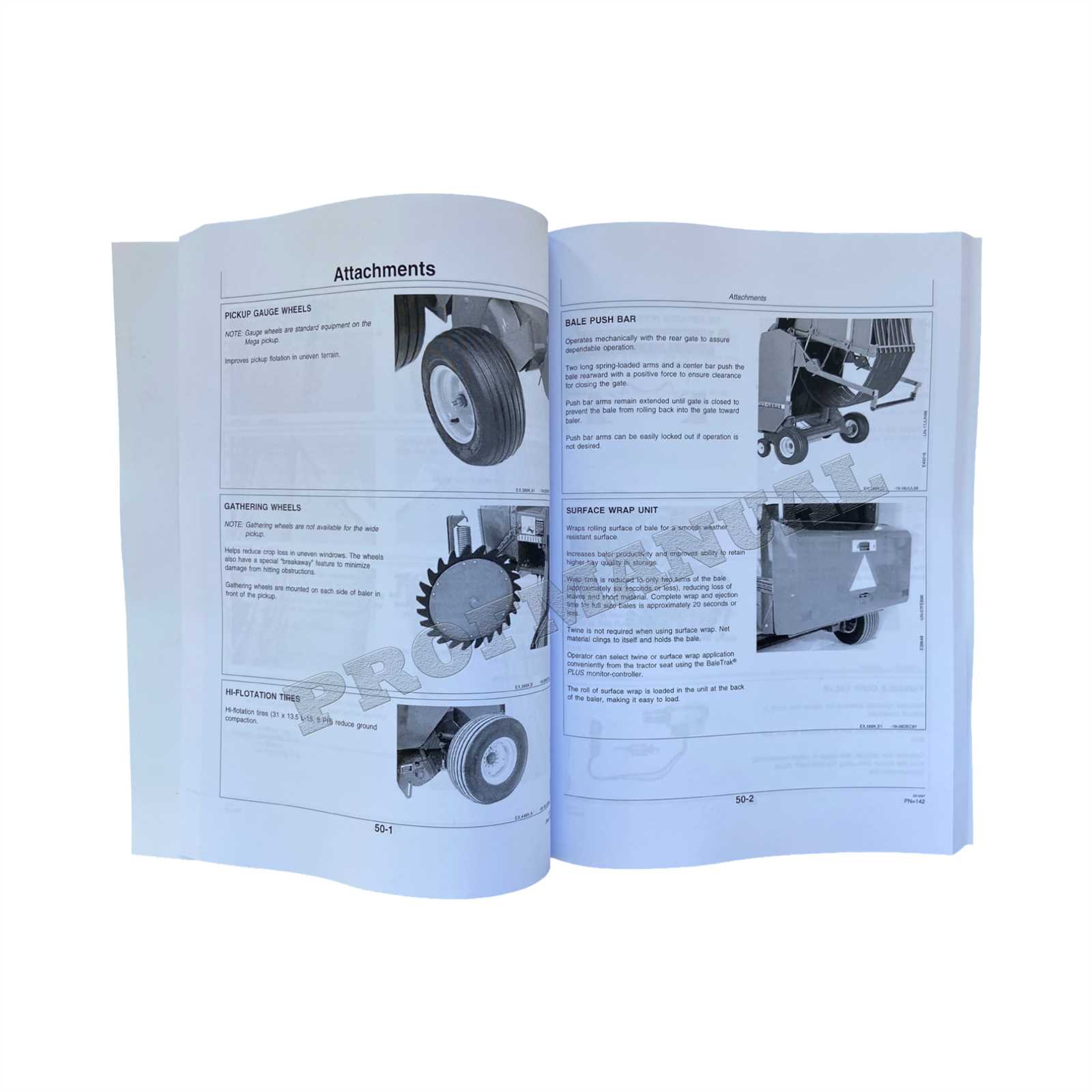

How to Read the Machinery Components Schematic

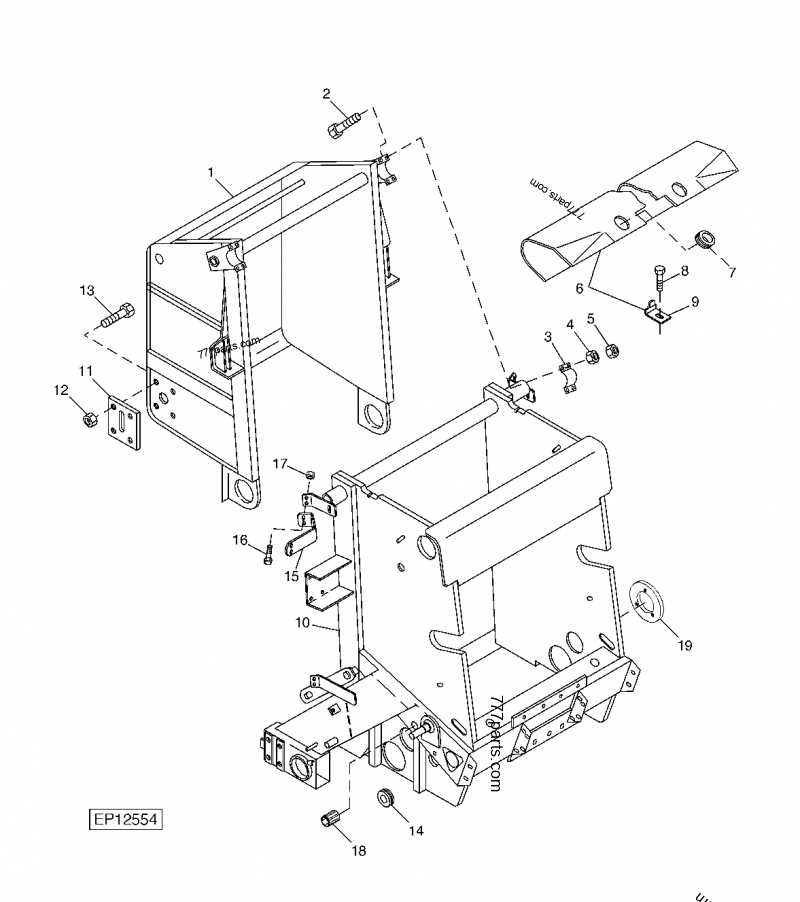

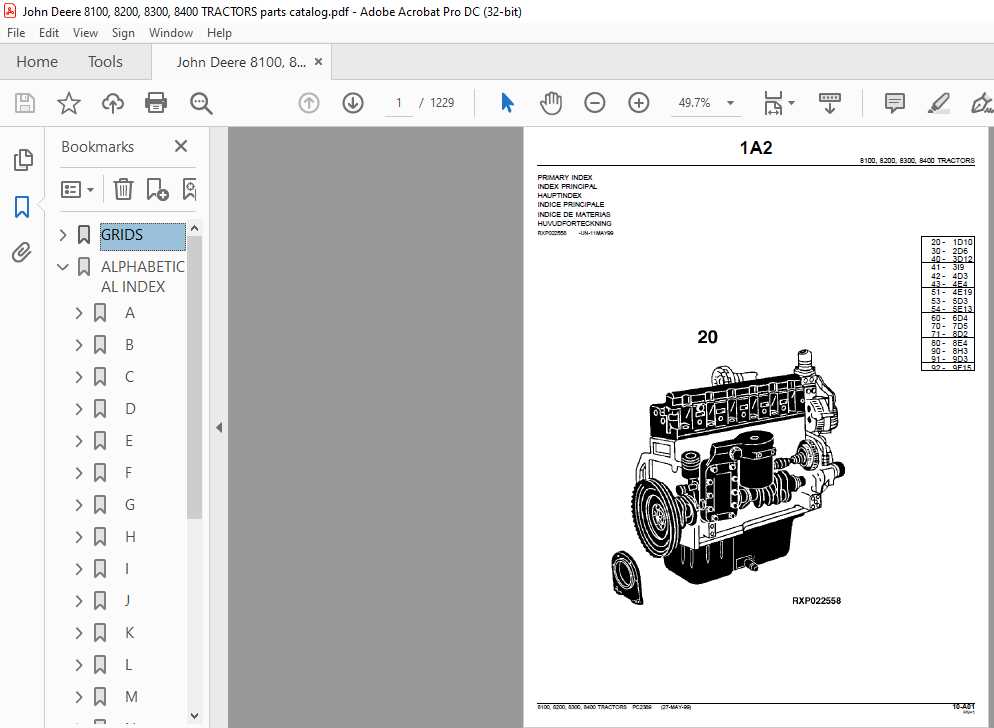

Understanding the schematic of farm equipment is essential for proper maintenance and repair. These visual representations provide a detailed view of the internal system, allowing operators and technicians to identify individual elements and their connections. By learning to read these schematics, you can quickly locate problematic areas and determine the best course of action for maintenance or replacement.

Typically, the schematic includes a variety of symbols and labels that correspond to specific components. The layout is organized to show how each part fits into the larger assembly, often with numbers or codes to identify individual pieces. The key to reading the schematic is recognizing these symbols and understanding the flow of operations within the system.

Steps to effectively interpret a schematic include:

- Identify Key Components: Look for labels or numbers that correspond to major parts such as motors, drive systems, or hydraulic components.

- Understand the Flow: Examine the layout to understand how each part connects to others and how they interact during operation.

- Locate Potential Issues: Focus on areas that seem unusual or where wear and tear could affect performance. These sections are often marked with specific codes or arrows to highlight areas of concern.

- Refer to the Legend: Use the included legend or key to decode any symbols or numbers you don’t immediately recognize.

By following these steps, you can decode the schematic and gain valuable insights into the machine’s mechanics. This knowledge not only helps you troubleshoot efficiently but also enables more informed decisions when replacing or repairing parts.

Common Issues with Agricultural Machine Components

Like any complex machinery, farm equipment is prone to a range of issues that can affect performance. Understanding the most frequent problems that arise with key components allows for quicker diagnosis and efficient solutions. Regularly checking the main elements of the system and being aware of common faults can prevent costly repairs and downtime during the busy seasons.

Several issues tend to occur more frequently, and addressing them early can save time and effort in the long run. These problems usually stem from wear and tear, improper maintenance, or environmental factors that impact the machine’s functionality.

- Hydraulic Failures: Leaks or pressure loss in the hydraulic system can hinder functionality, affecting critical operations such as material compression and part movement.

- Feed Mechanism Jams: Accumulation of debris or material clogging the feeding system can lead to stoppages or inefficient operation, causing strain on other components.

- Drive System Wear: Over time, drive belts and gears may experience excessive wear, leading to reduced power transfer and potential breakdowns.

- Component Misalignment: If parts are not properly aligned, it can cause friction, increased wear, or even complete failure of the affected systems.

- Electrical Issues: Wiring problems, faulty sensors, or electrical malfunctions can interrupt control systems and prevent the machine from operating as intended.

Regular inspection of these common problem areas is key to maintaining optimal performance. Taking proactive steps to address these issues ensures smoother operations and reduces the risk of unexpected failures during critical times. Regular servicing and immediate attention to emerging problems can significantly improve the machine’s lifespan and productivity.