Maintaining and operating farming equipment requires a deep understanding of its internal mechanisms. Every piece of machinery is made up of various elements that work together to achieve a specific function. Recognizing the role of each component helps in troubleshooting, maintenance, and ensuring the longevity of the equipment.

Visual aids can be invaluable in this process, offering clear insights into how individual parts are connected and function within the larger system. By studying these resources, operators can gain better control over the repair and upkeep of their machines.

In this guide, we will explore the critical components that make up the machine, providing an overview of their functions and offering practical tips on how to identify and replace them. Proper knowledge of these elements is essential for keeping the equipment running smoothly and avoiding unnecessary breakdowns.

Understanding Key Components of John Deere 569

Every piece of farming machinery is a complex system made up of numerous interconnected elements. Each component has a unique function that contributes to the overall performance of the machine. To ensure proper functionality and ease of maintenance, it is essential to understand how these parts interact and work together.

Main Mechanisms of the System

The core mechanisms that drive the functionality of this machine include the power transmission system, the feeding and compression system, and the ejection mechanism. These systems play vital roles in the overall efficiency of the machine, ensuring that each cycle is executed smoothly and consistently. Understanding how each part within these systems operates helps operators identify potential issues before they become serious problems.

Key Operational Elements

Among the most critical components are the gears, belts, and hydraulic systems, which facilitate the movement and control of various parts. Additionally, sensors and control panels allow operators to monitor performance and make adjustments as needed. Knowledge of these elements ensures that operators can handle routine maintenance tasks and troubleshoot problems when they arise.

How to Use the Baler Parts Diagram

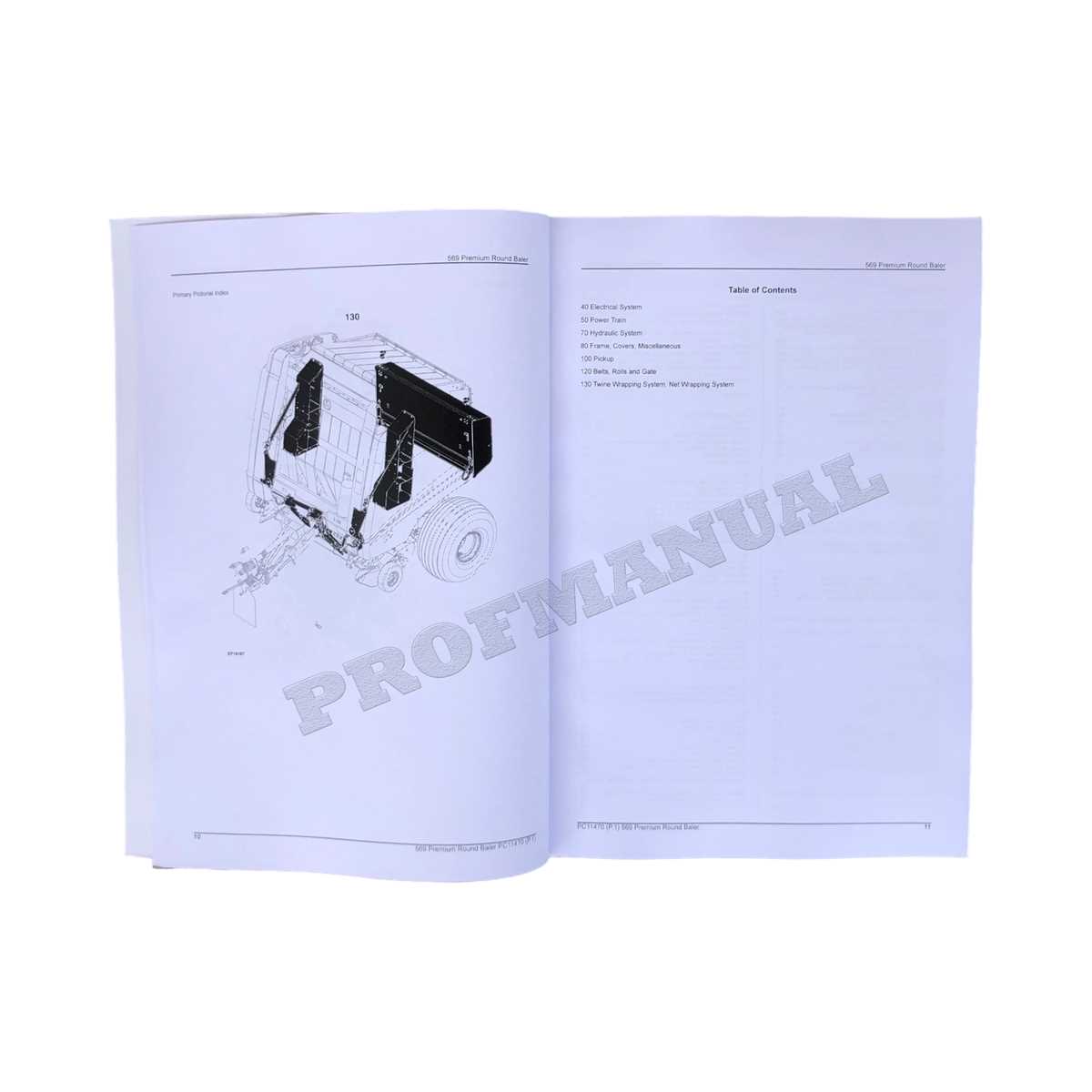

Visual guides are essential tools for understanding and working with complex machinery. They provide clear, structured information about the components of the system, their arrangement, and how they function together. By following these diagrams, operators can quickly identify specific elements, making maintenance and repairs more efficient.

When using a visual guide, start by familiarizing yourself with the layout of the diagram. Identify key sections and labels that correspond to the machine’s critical systems. This will help you navigate through the diagram and find the components you need to examine or replace.

Once you are comfortable with the general layout, focus on the details. Look for arrows, numbers, and annotations that indicate the relationship between various components. This will help you understand how parts interact and where issues may arise. With this knowledge, you can troubleshoot and perform routine maintenance more effectively.

Maintenance Tips for John Deere 569 Baler

Proper maintenance is essential for ensuring the longevity and efficiency of any heavy machinery. By performing regular checks and addressing issues promptly, you can prevent costly repairs and keep the equipment operating at peak performance. A consistent maintenance routine can also improve safety and reduce the risk of unexpected breakdowns.

One important maintenance task is regularly inspecting the hydraulic system. Ensure that all hoses are in good condition, free from cracks or leaks. Also, check fluid levels and replace them as needed to maintain optimal function. Pay attention to the belts and gears as well, keeping them clean and lubricated to prevent wear and tear.

Another key area is the feeding and compression system. Regularly clean these components to prevent debris buildup, which can lead to clogs or reduced efficiency. It’s also vital to inspect sensors and control panels for any signs of malfunction. Keeping these elements in good working condition ensures smooth operation and reduces the risk of costly repairs down the line.