Maintaining and repairing agricultural machinery is crucial for ensuring its longevity and optimal performance. Proper knowledge of the components that make up these machines is key for anyone involved in their upkeep. This section explores the intricate details of the parts that work together to achieve efficient functionality in farming tools.

By examining the structure of each element, operators can better diagnose issues, plan maintenance schedules, and address potential failures. Familiarizing oneself with the layout and interaction of different components enables smoother operations, minimizing downtime during critical farming seasons.

In this guide, we will focus on identifying the key features and functions of the various elements within a specific agricultural tool, offering insights on troubleshooting and maintenance. Whether you’re new to machinery or an experienced operator, understanding these fundamentals can save time and resources.

Understanding Key Components of the Hay Rake

In any farming equipment, it is essential to comprehend the specific roles each component plays in ensuring efficient operation. Every part within the machine contributes to its overall performance, allowing it to function smoothly and effectively. By familiarizing oneself with these elements, operators can better manage the machinery and detect potential issues before they become serious problems.

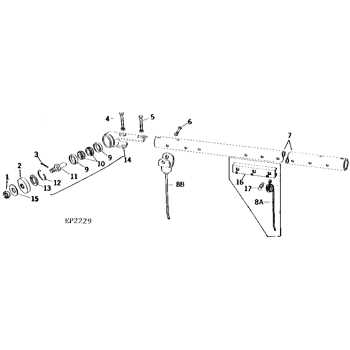

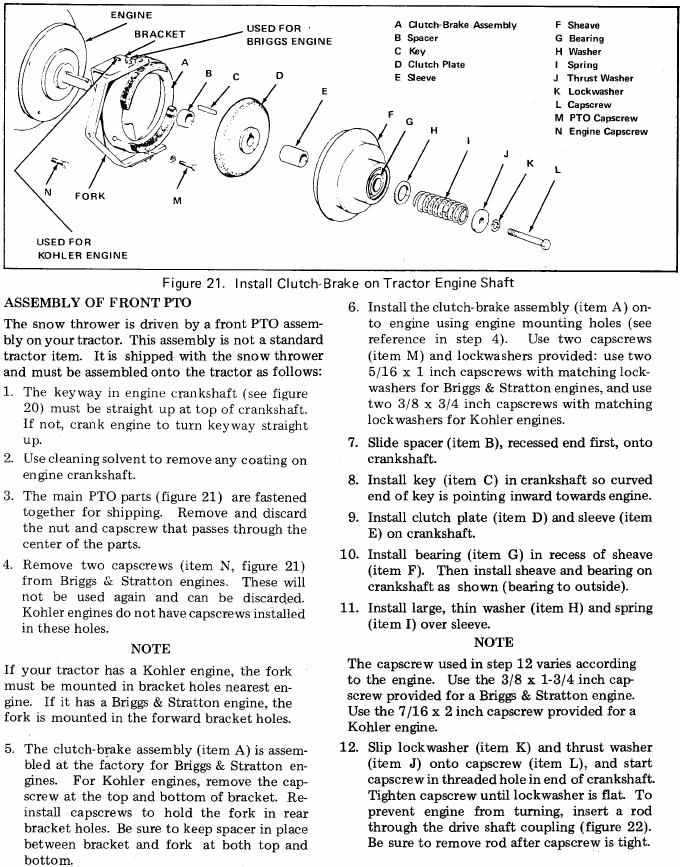

Key components include the mechanical elements responsible for moving and aligning materials, as well as those that support stability and precision during use. These interconnected features must work seamlessly to handle various agricultural tasks, from gathering to processing. Recognizing the importance of each part allows for more effective troubleshooting and ensures that the machine operates at its full potential.

Understanding these components also aids in proper maintenance. Regular inspection and care of these features prevent premature wear and enhance the machine’s longevity, ensuring that the equipment remains reliable through demanding seasons. Proper knowledge can save both time and money, making the machinery more efficient and durable over time.

Maintenance Tips for John Deere Rake Parts

Effective upkeep of agricultural machinery ensures optimal performance and extends the lifespan of essential components. Regular maintenance is crucial for identifying wear and tear early, preventing costly repairs, and keeping the equipment running smoothly. By focusing on a few key tasks, operators can maintain peak functionality throughout the season.

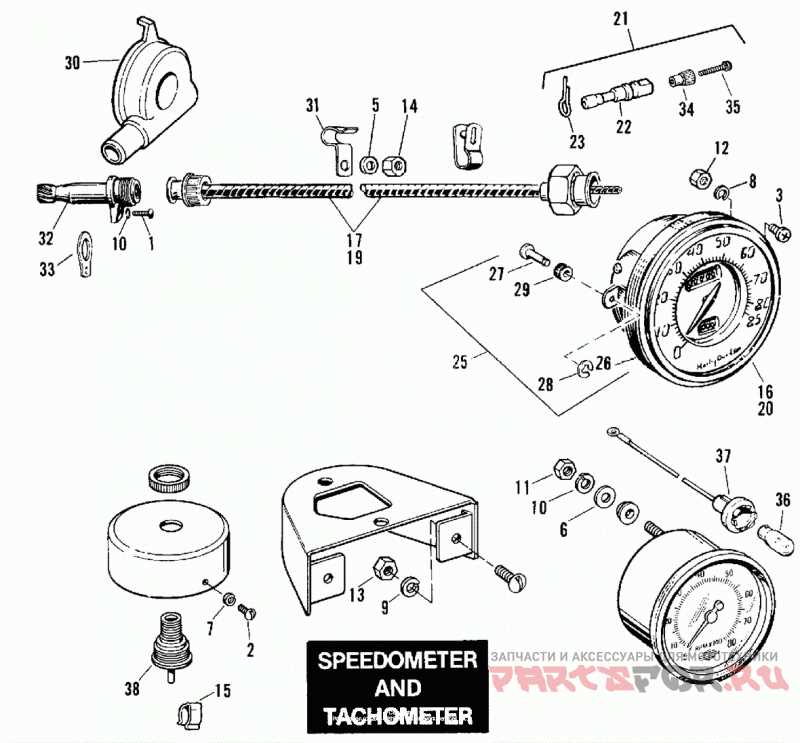

Regular Inspections and Lubrication

Routine inspections help identify potential issues before they become significant. Checking for loose or worn parts, such as belts and gears, can prevent malfunction. Additionally, lubrication is vital for reducing friction and ensuring smooth operation of moving components. Applying the appropriate lubricant to the necessary areas can greatly extend the life of mechanical parts and reduce the risk of damage.

Cleaning and Debris Removal

Removing debris and buildup from the machine after each use is essential for maintaining its performance. Dirt, grass, and other materials can clog moving parts, causing them to wear out prematurely. Regularly cleaning the equipment not only improves its efficiency but also reduces the chances of breakdowns during operation, especially when working in challenging conditions.

How to Identify Wear and Tear Signs

Recognizing the signs of wear and tear on machinery is crucial for maintaining its efficiency and preventing unexpected failures. Over time, the constant movement and pressure on various components can lead to damage, which can impair the overall function. Identifying these signs early allows operators to address issues before they escalate into more costly repairs.

Common Indicators of Damage

One of the most common signs of wear is visible damage such as cracks, dents, or bent parts. Regularly inspecting the mechanical components for any signs of unusual movement or misalignment can also indicate wear. Excessive vibration during operation can point to imbalanced or worn-out parts that need attention. Additionally, if certain components are not functioning as smoothly as they once did, it may be a sign of internal damage.

Listening for Unusual Sounds

Another effective way to spot wear is by paying attention to any abnormal sounds coming from the machine during operation. Scraping, grinding, or squeaking noises often point to friction or damaged bearings. These noises should never be ignored, as they could signal that a part is failing or is already in a state of disrepair. Timely action based on these indicators can help prevent more extensive damage.