Maintaining agricultural machinery requires a clear understanding of each component’s function. For any equipment to run efficiently, it is essential to be familiar with its structure and individual elements. This knowledge helps ensure proper upkeep and quick identification of issues when they arise.

Proper maintenance starts with knowing the exact layout and function of every part, whether you’re replacing a damaged element or performing routine checks. Understanding the mechanical design is crucial in extending the lifespan of the machine and minimizing downtime.

Regular inspections and proper care based on a thorough understanding of these components can greatly improve the overall performance of the machinery. Having a clear visual reference and a systematic approach to repairs is vital for both experienced technicians and novice users alike.

Understanding the John Deere 709 Cutter Parts

When dealing with large machinery, knowing the various components that make up the equipment is essential for its operation and maintenance. Each element plays a crucial role in ensuring the smooth functioning of the system, and understanding their design helps with troubleshooting and repairs. In this section, we’ll focus on key elements that contribute to the machine’s performance and how to recognize them for maintenance.

Key Components of the Machine

The primary sections that make up the equipment include several mechanical and structural parts. Knowing how each piece fits into the overall structure is essential for effective management. Here are some of the key parts:

- Blade Assembly: The cutting mechanism that interacts with the soil and vegetation.

- Gearbox: Transfers power from the engine to the blades, ensuring proper rotation.

- Spindle: A rotating shaft that holds the blades and helps them move efficiently.

- Deck: The main body housing the cutting mechanism and protecting other elements.

Importance of Regular Inspections

Regular inspections ensure that all components are functioning as intended. A failure to notice wear and tear in specific parts can lead to severe mechanical problems. Here are some aspects to consider:

- Check for blade damage and sharpness.

- Inspect the spindle housing for any cracks or signs of wear.

- Ensure the gearbox fluid is at the proper level to prevent overheating.

- Look for any obstructions around the deck that could cause damage during operation.

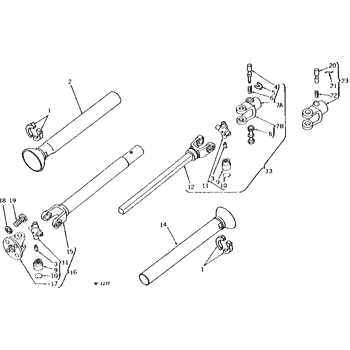

How to Read the Parts Diagram

Understanding the layout and components of a machine is crucial for effective maintenance and repairs. A well-detailed visual representation helps users to easily identify the elements of the equipment and their functions. The key to using this guide effectively is knowing how to read the visual cues and how they correlate with the physical parts in the machinery.

Typically, each component is clearly labeled, and the diagram is designed to make it easier to locate parts that need attention. By following the markers and labels, you can identify both major and minor components, which simplifies troubleshooting and ensures the right part is replaced or serviced. Understanding this guide allows for better decision-making during the repair or maintenance process.

Reading the diagram requires attention to detail. Each section is often color-coded or numbered to distinguish the different elements. Familiarize yourself with these markings to locate parts quickly and understand their relationships within the larger system.

- Identify Labels: Each part is usually labeled with a number or code, making it easier to find in manuals or replacement guides.

- Understand Part Groupings: Parts are often grouped based on function or location on the machine.

- Check for References: Diagrams may include additional references or descriptions that explain the function of each component.

Common Maintenance for Rotary Cutter Parts

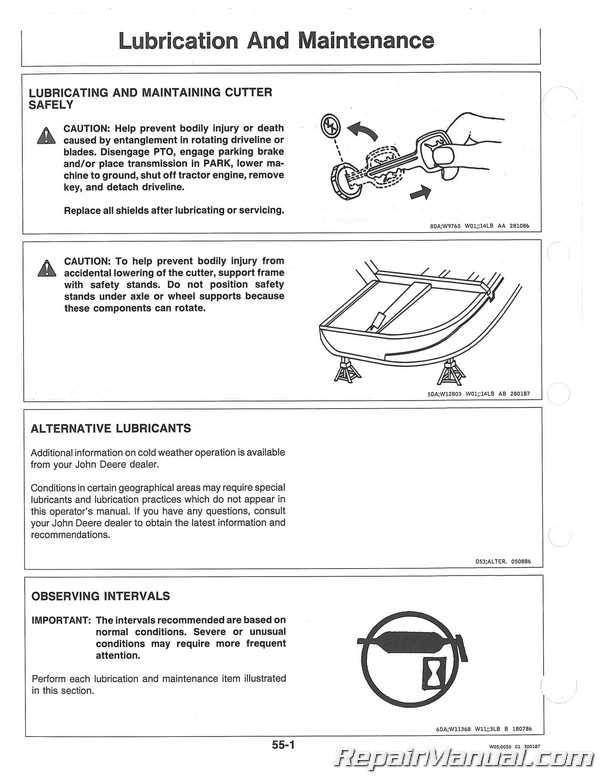

Regular upkeep is essential for ensuring that your agricultural equipment continues to operate efficiently. Each component must be maintained to avoid breakdowns and prolong the life of the machine. Proper care prevents minor issues from becoming major problems, saving time and money in the long run.

Essential Maintenance Tasks

Performing routine maintenance on your machine involves several critical steps. Keeping everything in top condition involves checking for wear, replacing worn-out components, and cleaning essential parts. Here are some key tasks:

- Blade Inspection and Sharpening: Regularly check for damage or dullness. Keeping blades sharp ensures optimal cutting performance.

- Fluid Levels: Ensure that the necessary fluids, such as oils and greases, are at proper levels to avoid overheating or friction issues.

- Check Fasteners: Inspect bolts and screws to ensure they are tight and secure. Loose fasteners can lead to mechanical failure.

Cleaning and Lubrication

Proper cleaning and lubrication are vital for smooth operation. Dirt, debris, and old lubricants can cause parts to wear out prematurely or function inefficiently. Regularly clean the machine and apply fresh lubrication where necessary to avoid these issues.

- Deck Cleaning: Remove dirt, grass, and other debris that could obstruct the machine’s function or cause corrosion.

- Lubricate Moving Parts: Apply lubricant to gears, spindles, and other moving components to reduce friction and wear.