Understanding the inner workings of farming machinery is essential for efficient operation and long-term durability. Whether you are a seasoned professional or new to agricultural machinery, having a comprehensive understanding of how different elements work together can make a significant difference in performance and maintenance.

In this guide, we will explore the essential components of a specific type of field equipment, offering insight into its design and structure. By breaking down the different sections and their functions, you will gain a clearer picture of how these parts interact to optimize agricultural tasks.

Proper care and maintenance are crucial to keeping equipment running smoothly. Knowing where and how to identify wear or damage in the machine can save time, reduce costs, and improve efficiency. Understanding the key components helps ensure that you can address any issues promptly, keeping your machinery in top condition.

Understanding Agricultural Equipment Design

Farm machinery is engineered for efficiency, precision, and durability. To optimize performance, it’s essential to comprehend the layout and design of each element within the system. Understanding how the various components work together allows operators to maximize functionality while minimizing downtime and maintenance needs.

Structural Overview

The design of such equipment focuses on achieving balanced functionality with robust construction. It includes various sections, each playing a pivotal role in ensuring smooth operation. From the frame that supports the entire structure to the moving elements that handle soil and seed placement, every detail is carefully crafted for specific tasks.

Operational Efficiency

Efficiency in operation is a result of well-designed systems working in harmony. The equipment’s design includes features that reduce wear, increase productivity, and enhance user control. Understanding these elements gives operators better insight into how adjustments can improve performance and reduce operational costs.

Key Components of Agricultural Equipment

Understanding the primary elements of field machinery is crucial for maximizing performance and ensuring long-lasting reliability. Each component is designed to serve a specific function, contributing to the overall efficiency of the equipment. A closer look at these critical sections helps identify how they interact and what role they play in the machine’s operation.

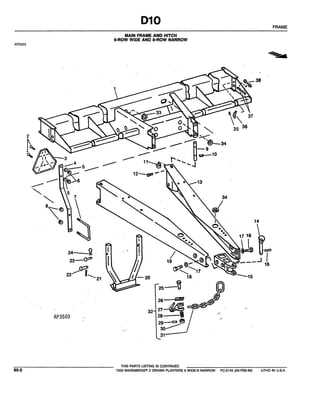

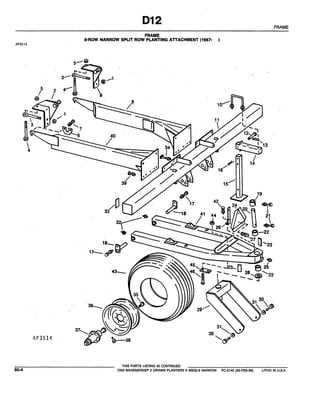

Frame and Structure

The frame serves as the backbone of the equipment, providing stability and support for all other components. Its durable construction ensures that the machine can withstand harsh working conditions, while its design allows for easy integration with other essential systems. The frame’s role is vital for maintaining proper alignment and function during operation.

Seeding Mechanism

The seeding mechanism is one of the most critical parts of the system, responsible for accurate seed placement. Precision in this area is essential for ensuring even distribution and optimal growth conditions. Different models feature various seeding systems, but all focus on delivering seeds to the soil at the right depth and spacing.

Maintaining Your Agricultural Equipment

Proper maintenance is essential for ensuring the longevity and optimal performance of farm machinery. Regular inspections and upkeep not only prevent unexpected breakdowns but also contribute to better productivity and cost savings over time. Understanding the specific needs of each component allows for more efficient care and extends the life of the equipment.

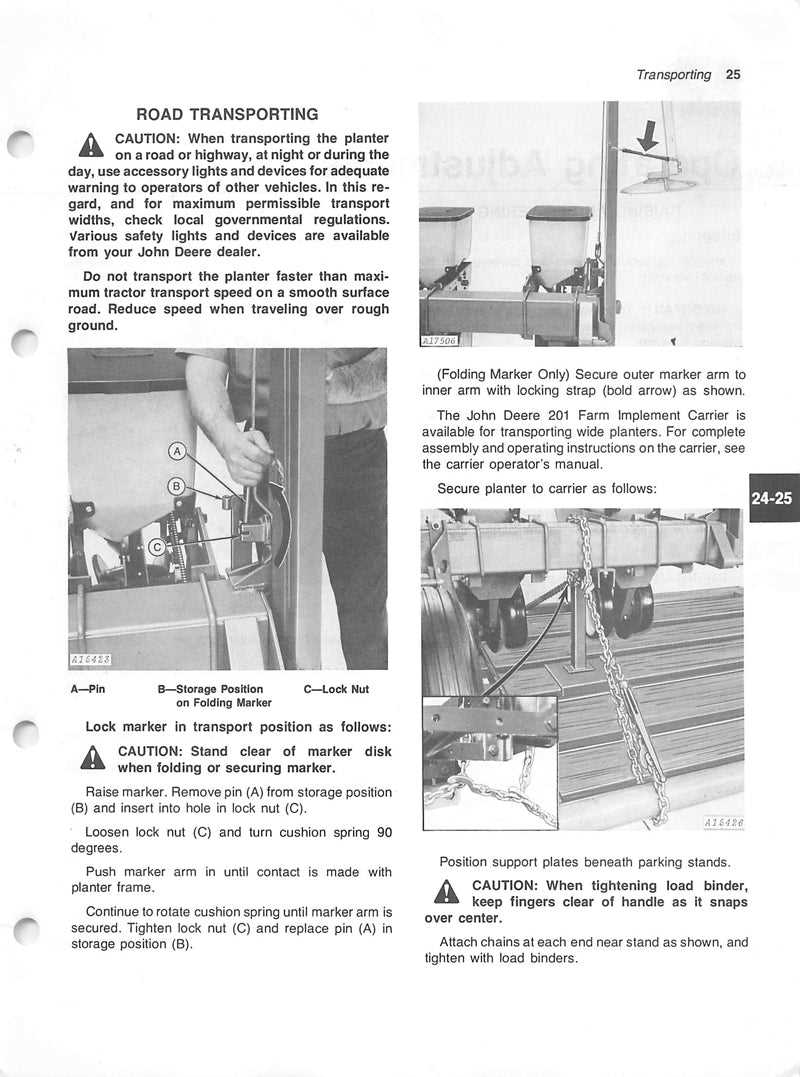

Routine Inspections

Regular checks are crucial for identifying wear and tear before it becomes a major issue. Inspecting the frame, wheels, and other moving parts can help catch any signs of damage or misalignment early. This proactive approach ensures that small problems are addressed before they affect the overall functionality of the machine.

Lubrication and Adjustments

Proper lubrication reduces friction and prevents parts from wearing out prematurely. It is essential to apply the right lubricants to key components, ensuring smooth operation and reducing the risk of breakdowns. Additionally, making minor adjustments to the tension and alignment of moving parts can improve efficiency and prevent unnecessary strain on the system.